BAER HSSG Short Machine Tap Form B - M 2 x 0.4

BAER HSSG Short Machine Tap Form B - M 2 x 0.4

Short machine taps allow you to cut a finished thread with just one tool in one step, even by hand. Exact internal thread can be cut by hand or semi-professionally by machine to save time.

Compared to the machine tap, the short machine tap has a short shank. This allows you to cut internal thread by hand without jamming and can be operated with tap wrenches, tool ratchets or other holding tools with square drive.

The thread can be cut in a pre-drilled core hole and does not require any preparatory work by a taper tap (No. 1) or intermediate tap (No. 2).

This internal tap clearly offers the price advantage over the hand tap set, as you no longer need two or three screw taps for thread cutting, but only one screw tap. Due to the high time saving in the process, the efficiency of the thread cutting is also significantly increased.

The tap can be used for through holes, as the long gate, the straight flutes and the spiral point ensure that the chip is transported forward out of the hole.

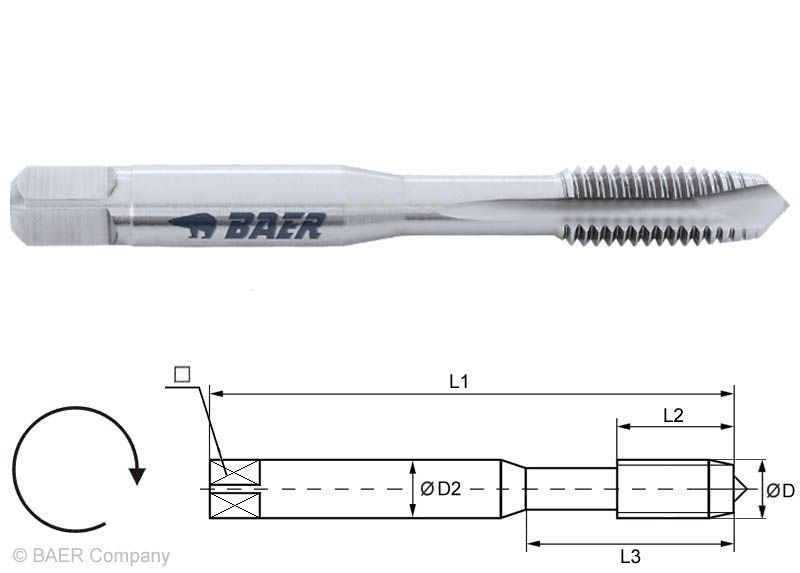

Dimensions

| Diameter |

2 |

|---|---|

| Nominal diameter in inches |

0,079 |

| Nominal diameter in mm |

2 |

| Pitch |

0,4 |

| Pitch in mm |

0,4 |

| Dimension |

M 2 x 0,4 |

Characteristics

| Product group |

Screw taps |

|---|---|

| Product type |

Short machine taps |

| Thread standard |

M: Metric ISO standard thread according to DIN 13 |

| Tolerance |

ISO2/6H |

| Direction |

Right |

| Standard |

DIN 352 |

| Tensile strength at room temperature |

up to 800 N/mm² | 22.2 HRC |

| Material |

HSSG bright |

1.6 mm

Through hole up to 4 x D

Form B with spiral point

4-5 threads

Chips are removed downwards in the direction of cutting

External cooling and lubrication

HSSG bright

up to 800 N/mm² | 22.2 HRC

ISO2/6H

Applications

- Materials with good machinability up to 800 N/mm²

- Unalloyed and low-alloy steels

Technical drawing

| D1 |

M 2 x 0.4 |

|---|---|

| D2 |

2,8 mm |

| L1 |

36 mm |

| L2 |

8 mm |

| Diameter |

2 |

| Square |

2,1 mm |

Application – Sample materials for taps

| Unalloyed construction steels | |

|---|---|

| 1.0035 | S185 (St33) |

| 1.0036 | S235JRH |

| 1.0038 | RSt37-2 |

| 1.0039 | S235JRG1+CR |

| 1.0044 | St44-2 |

| 1.0060 | E335 (St60-2) |

| 1.0116 | St37-3 |

| 1.0570 | St 52-3 |

| Alloyed construction steels | |

|---|---|

| 1.5415 | 15Mo3 |

| 1.5423 | 16Mo5 |

| 1.5622 | 14Ni6 |

| 1.7335 | 13CrMo44 |

| 1.7337 | 16CrMo44 |

| 1.7715 | 14MoV63 |

| Free-cutting steels | |

|---|---|

| 1.0711 | 9S20 |

| 1.0715 | 9SMn28 |

| 1.0718 | 11SMnPb30 |

| 1.0721 | 10S20 |

| 1.0723 | 15S20 |

| 1.0726 | 35S20 |

| 1.0737 | 9SMnPb36 |

| 1.0758 | 60SPb20 |

| Case-hardening steels | |

|---|---|

| 1.0401 | (C15) |

| 1.7016 | 17CR3 |

| 1.7131 | 16MnCr5 |

| 1.5919 | 15CrNi6 |

| Quenched and tempered steels unalloyed | |

|---|---|

| 1.0402 | C 22 |

| 1.1151 | C22E (Ck22) |

| 1.0503 | C 45 |

| 1.1191 | C45E (Ck45) |

| Cast steel | |

|---|---|

| 1.0420 | GS-38 |

| 1.5419 | GS-22 Mo 4 |

| 1.6750 | GS-20 NiCrMo3 7 |

| 1.7357 | GS-17 CrMo 5 5 |

| Malleable cast iron | |

|---|---|

| 0.8145 | EN-GJMB 450-6 |

| 0.8170 | EN-GJMB 700-2 |

| 0.8045 | EN-GJMW-450-7 |

| 0.8055 | EN-GJMW-550-4 |

| Pure copper low-alloyed | |

|---|---|

| 2.0240 | CuZn15 |

| 2.0265 | CuZn30 |

| Brass short-chipping | |

|---|---|

| 2.0401 | CuZn39Pb3 |

| Brass long-chipping | |

|---|---|

| 2.0321 | CuZn37 |

| 2.0335 | CuZn36 |

| 2.0360 | CuZn40 |

| Aluminum cast Si > 5-12 % | |

|---|---|

| 3.2161 | G-AlSi8Cu3 |

| 3.2163 | G-AlSi9Cu3 |

| 3.2381 | G-AlSi10Mg |

| 3.2583 | G-AlSi12(Cu) |

| Lamellar graphite cast iron | |

|---|---|

| 0.6010 | EN-GJL 100 (GG-10) |

| 0.6020 | EN-GJL 200 (GG -20) |

| 0.6025 | EN-GJL 250 (GG-25) |

| 0.6030 | EN-GJL 300 (GG -30) |

| Copper-tin alloy (bronze) short-chipping | |

|---|---|

| 2.1090.01 | G-CuSn7ZnPb |

| 2.1086.01 | G-CuSn10Zn |

| 2.1097 | G-CuSn5ZnPb |

| Pure copper, low-alloyed copper | |

|---|---|

| 2.0240 | CuZn15 |

| 2.0265 | CuZn30 |