Why the pitch of the thread is so important

What is the thread pitch anyway?

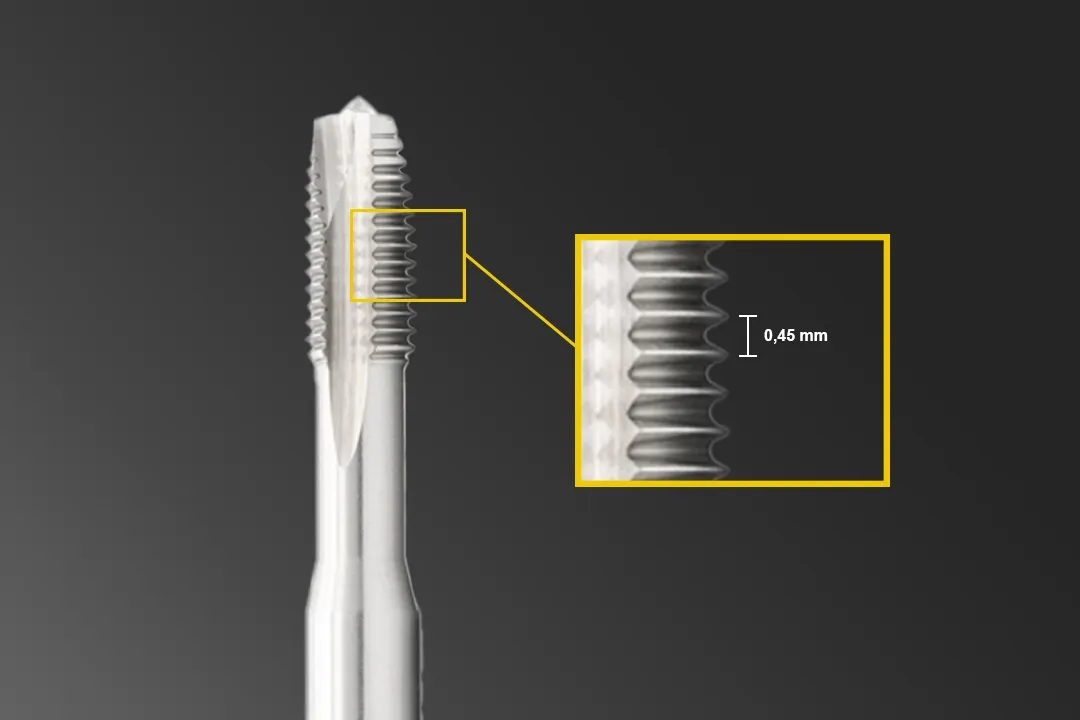

If you've already noticed that you don't actually know that much about the pitch, don't worry: we'll start small. First, imagine the profile of a tap. Now you can see the peaks and valleys that result from the adjacent threads. The distance between two of these thread peaks is the pitch. It corresponds to the distance traveled per revolution in the axial direction. In other words, if you turn a screw once through 360°, it will move as far into the receiving thread as the pitch corresponds to.

And what about thread profiles without a recognizable point? For threads such as a trapezoidal thread, extend the thread flanks in an imaginary line until they meet and you will have thread tips between which you can measure the thread pitch. You can also read the pitch from a thread table or directly from your tap or the packaging or product page. For many threads, such as the metric fine pitch thread, the pitch is also part of the thread designation.

The pitch works as described above for single-start metric threads. We will go into the exceptions to this rule in more detail in a moment.

The pitch has this influence on the thread

First, let's take a look at what the pitch actually means for the properties of a thread. Threads with a large pitch are called coarse threads or standard threads, those with a smaller pitch are called fine threads. All common collections of standards, be it the metric DIN threads, the American UN threads or the British BS threads - include a coarse thread and one or more fine threads.

Coarse threads are more robust, do not tear out as easily and are better able to withstand dirt and damage. Screws with a coarse thread can also be installed more quickly, as the greater pitch means that more distance is covered per revolution when screwing in. On the other hand, fine threads have a higher self-locking effect and are better equipped to resist self-loosening due to shocks or vibrations. The smaller pitch also ensures that screws with fine threads can be adjusted very precisely, which is important for adjusting screws. Fine threads also have a shallower thread depth and can be easily cut into components with thin walls.

You should be able to distinguish the designations for the pitch

The pitch for multi-start threads

And there is another exception to the conventional way in which the incline works. However, you will rarely be confronted with such a case in normal applications. We are talking about multi-start threads. These are threads that have two or more threads. This means that several threads wind around a bolt and the thread flanks facing each other or the neighboring thread tips no longer belong to the same thread. Accordingly, we must adapt the definition of the pitch for these cases. Now it is no longer about the distance between neighboring thread tips, but between two thread tips that belong to the same thread. Depending on how many threads are used, very large pitches can be achieved. And since the pitch also determines the distance traveled when screwing in, it is easy to understand why these cases are also referred to as high-speed screwing.

But even with multi-start threads, the distance between directly adjacent thread tips is still a factor. It is no longer referred to as the pitch, but as the pitch. The relationship between the two values can be expressed by the formula Number of threads = pitch : division.

In the BAER online store you will find taps and dies with every conceivable pitch. And we will be happy to manufacture anything that is not yet available for you. Just ask our competent customer service team!