When thread protection is really necessary

Threads are strong all-rounders that give your components the necessary hold. But they also have a sensitive side! This is because the geometry of a thread consists of a complex interplay of many different angles, diameters and other dimensions, and if something goes wrong, it is not uncommon for the entire thread to become unusable. It may therefore be necessary to provide your threads with special protection to prevent deformation and contamination and thus guarantee smooth operation and a long service life. If you protect your threads well, you will save time and money. But in which cases do you need such thread protection and what options do you have to protect a thread optimally? We explain this in this blog post.

What should you protect your thread from?

Of course, not every thread needs thread protection. There are often very specific cases in which threads are exposed to particular mechanical loads or in which contamination can easily occur, making thread protection indispensable.

Thread protection in production

The serial production of large components can sometimes be a little more rough and tumble. Handling threads that have already been cut with particular care could lead to delays and is not feasible in many cases. It is much easier to secure threads during production with special thread protection. Thread protection does not only apply to mechanical damage. Thread protection is also necessary when painting components in order to prevent the threads from being clogged by the paint.

Thread protection for transportation and storage

After production, the adventure really begins for many components. Preparing threads for long transport routes with suitable thread protection ensures that the customer receives the products in the same quality as when they left production. The thread protection also prevents dust and corrosion during subsequent storage. So it doesn't matter whether the threaded component is waiting hours, days or weeks to be used.

Thread protection for at home

Although thread protection is less relevant outside of industrial manufacturing processes, it does have a right to exist here too. Sensitive fine threads and threads that perform safety-relevant tasks should be protected with thread protection to prevent them from losing their functionality. Thread protection can also be useful in dirt-prone working environments such as a car workshop, saving time and effort.

What types of thread protection are there?

If you have now determined that you should also use thread protection, you are now spoiled for choice. Because there is a wide range of products with which you can reliably achieve such thread protection.

Caps and plugs without thread

Non-threaded caps and plugs are a quick and flexible thread protection solution that protects against impact as well as dirt and moisture. They are suitable for several thread sizes and can be fitted and removed quickly. However, they do not hold as well as other variants.

Threaded caps and plugs

Threaded caps and plugs must fit exactly to the type of thread they are intended to protect. You therefore need to take a close look at this type of thread protection. They also take a little longer to fit and remove. On the other hand, this is a very reliable thread protector that can withstand shocks and vibrations.

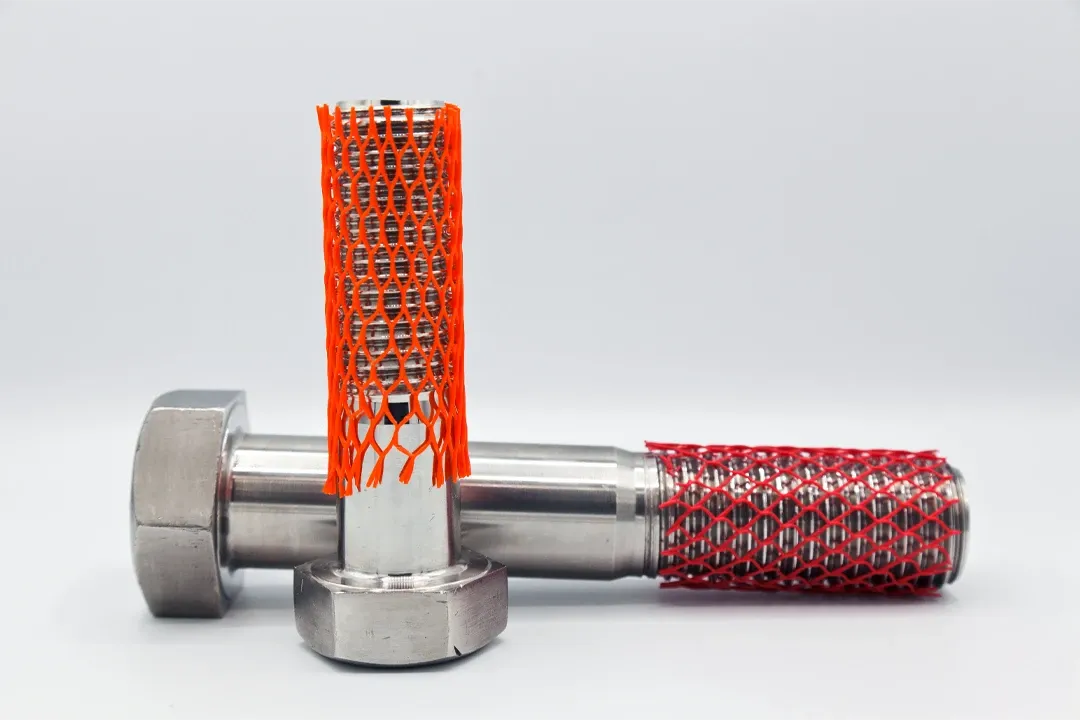

Mesh protection caps for external threads

Mesh protection caps are only suitable for external threads. This thread protection is easy to fit and provides good protection against damage. However, the mesh principle means that there is no protection against liquids and only limited protection against dust and dirt.

Nuts for thread protection

Thread protection also works by screwing an appropriate nut onto the thread. Special products are available for some areas of application. The very sensitive thread for attaching silencers to a gun must be well protected so that the perfect alignment with the trajectory of the bullet is not impaired. For this purpose, there are special nuts that serve to protect the thread when the silencer is not in use.

Thread protection with masking tape

A quick and low-threshold option for thread protection is to wrap the thread with masking tape. However, this method is not without its pitfalls, as residue from the adhesive can do more harm than good. This thread protection therefore only works with high-quality, residue-free adhesive tape and only for very short-term use.

What you need to look out for when choosing thread protection

How do you find the right thread protection for your application from the many options available? First of all, you should consider what you need the thread protection for. Do you want to prevent damage during production, prepare the component for storage or will your thread be exposed to special conditions? This will give you an initial indication.

The next consideration concerns the environmental influences that could affect the thread. Do you only need thread protection to protect the thread from knocks and impacts, or will moisture, high temperatures or a particularly dirt-prone working environment play a role? It is not only the shape, but also the material of your thread protector that is decisive here. PVC, for example, can cope well with vibrations, while silicone can also withstand high temperatures. For special cases such as contact with chemicals, you need to use resistant materials.

And finally, of course, it is also relevant how uncomplicated the installation and removal of the thread protector can or should be. In most cases, you have to weigh up speed against safety and consider how long the thread protector will remain on the thread.

Of course, before you can protect the thread, you first have to produce it. And that's where we come in! In the BAER online store you will find threading tools in all shapes and sizes. Why not take a look?