Each thread profile consists of a wealth of

precisely coordinated dimensions and angles. Much more than you may realize. The good thing is that you don't need to know them all to cut perfect threads.The manufacturer does the tedious calculations for you and guarantees that the thread dimensions will fit as desired in the end.However, there are a few variables on the thread profile that you should have heard of. If only because they are essential for choosing the right tap for your project. One of these particularly important variables is the

flank angle.

The flank angle is one of the decisive factors that clearly define the thread profile. As the flank angle does not differ for some of the most common thread types, its importance is sometimes not fully recognized. But at the latest when you have to deal with foreign standards or venture into the area of movement threads, you can no longer avoid the correct flank angle. To ensure that you are always prepared, we have summarized all the important facts and figures on the subject of flank angles.

Where is the flank angle located in the thread profile?

As always, let's start from the beginning.

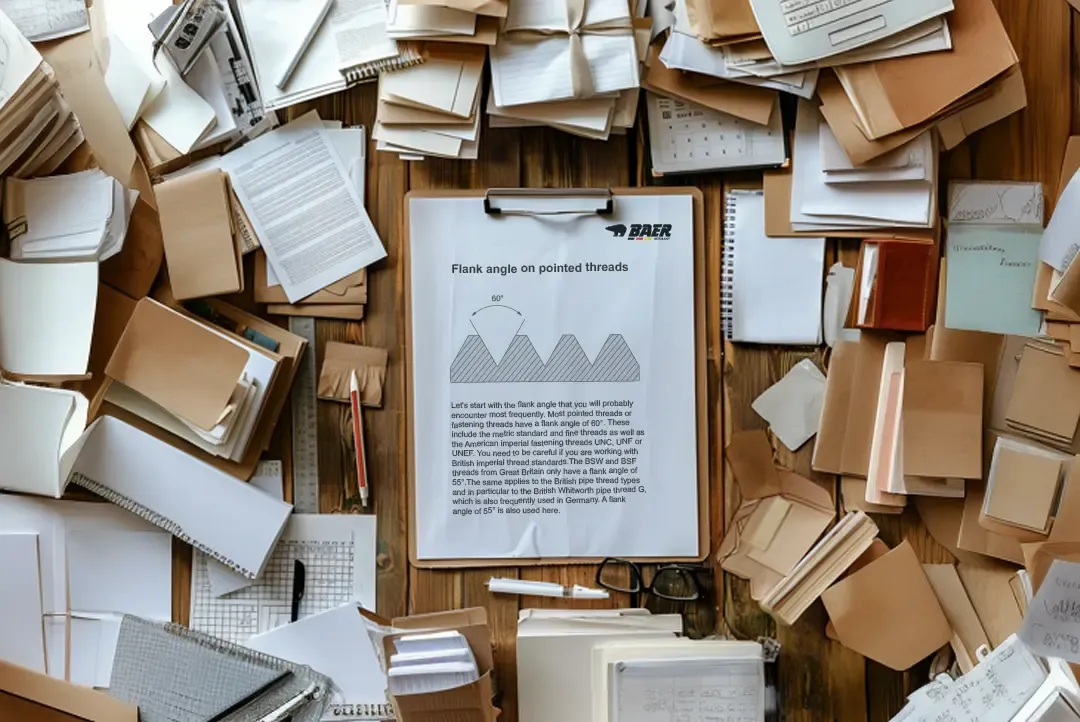

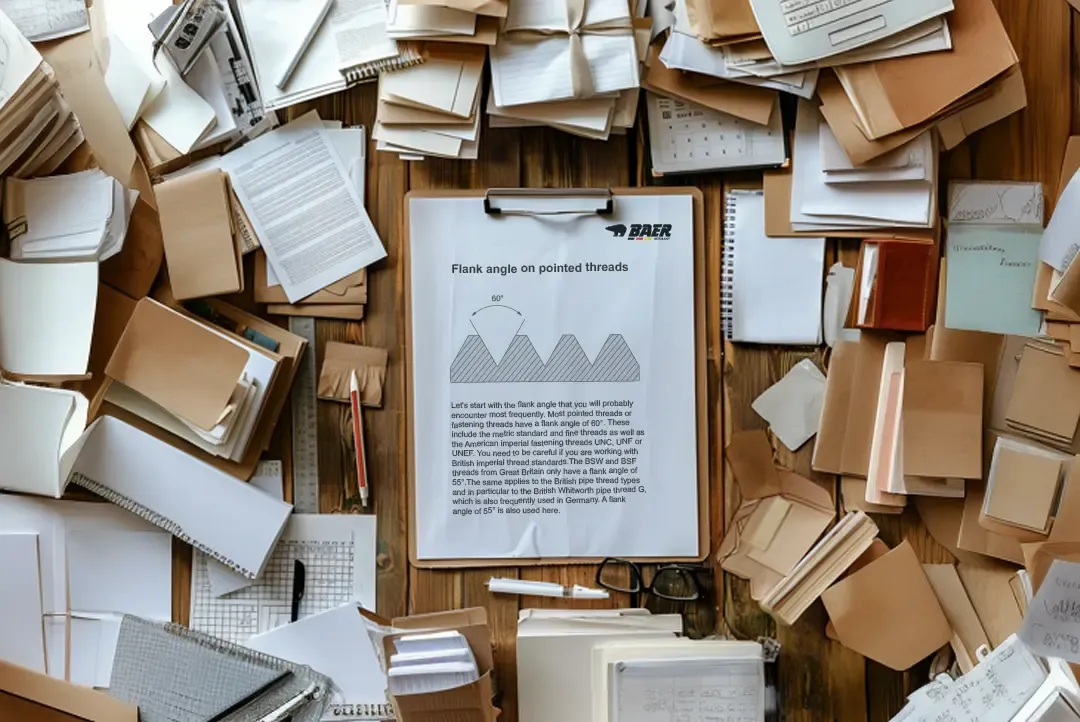

What actually is the flank angle?To locate the flank angle correctly, we need to imagine our thread in the profile. To do this, we saw through a tap or screw lengthwise (in our minds!) and take a look at the edges of the cut surface. The thread in the profile now looks like a jagged line or a mountain range in which one pointed mountain follows the next. And just as in the mountains, the two inclined planes that together form a mountain are called flanks. The flank angle lies between two flanks facing each other.

With a conventional pointed thread, this image works wonderfully to visualize the position of the flank angle. But what about other thread forms? Thread types such as trapezoidal or round threads, which do not produce such a beautiful seamless mountain chain in the profile, naturally also have a flank angle. In such cases, all we have to do is extend the thread flanks by an imaginary line until they also meet at some point to form points. The angle in between is then the flank angle.

What effects does the choice of the correct flank angle have?

The flank angle influences the friction and self-locking of threads. Applied to a screw connection, it can therefore be said that the flank angle determines (among other factors) how easily a screw can be loosened. The smaller the flank angle, the smoother the thread. How much friction or self-locking is desired depends on the intended use of a thread.For example, thread types that are mostly used for motion threads have a small flank angle.In these cases, a firm hold is not helpful. The situation is different for classic fastening threads, which must not come loose by themselves and therefore require good self-locking. A larger flank angle is then used.

These flank angles are frequently used

Flank angles are important and unchangeable components of thread standards and are the result of precise calculations combined with many years of experience. As a result, only a few different flank angles are used in modern thread types. Nevertheless, you must pay particular attention here and find out which flank angle you are working with. This is because even slight deviations in the flank angle prevent threads from being compatible.

Flank angle on pointed threads

Let's start with the flank angle that you will probably encounter most frequently. Most pointed threads or fastening threads have a flank angle of 60°. These include the metric standard and fine threads as well as the American imperial fastening threads UNC, UNF or UNEF. You need to be careful if you are working with British imperial thread standards.The BSW and BSF threads from Great Britain only have a flank angle of 55°.The same applies to the British pipe thread types and in particular to the British Whitworth pipe thread G, which is also frequently used in Germany. A flank angle of 55° is also used here.

Flank angles on movement threads

The flank angles on movement threads are significantly lower than these values and are usually around 30°. These include the metric ISO trapezoidal thread Tr with 30°, the metric saw thread S with 33° and the round thread Rd with 30°. But beware, there are also international variations in the movement threads. The American trapezoidal thread ACME has a flank angle of 29°. A small but significant deviation from its metric counterpart.

Special flank angles

While the absolute majority of all threads can be described by the flank angles mentioned above, there are of course also a few deviations and curiosities.

For many types of saw thread, for example, the flank angle is made up of two values. Saw threads are designed for one-sided loads and, unlike other thread types, do not have a symmetrical profile, but one that actually resembles the shape of a saw tooth. A distinction is made between the load-bearing and non-load-bearing flanks. The flank angle is the angle between an imaginary line running perpendicular to the axis and these two flanks, e.g. 30°+3° for metric saw threads.

Threads with conspicuously large or small flank angles are often older thread types that are no longer in use. Not yet completely extinct but well on the way to this category is the steel armor pipe thread with an 80° flank angle.There were once even historical threads with a 0° flank angle, i.e. a completely right-angled thread profile. These were the forerunners of today's trapezoidal threads. However, the rectangular shape was not only very difficult to produce, but also quite susceptible to mechanical wear and was quickly abandoned in favor of models with a larger flank angle.

No matter which flank angle you need - we are guaranteed to have the right tap or die for you in the BAER online store. Take a look around and don't hesitate to contact us with your questions and concerns.