The saw thread is a specialist among thread types

Thread types are a dime a dozen. You will certainly have noticed this if you have ever needed a thread for something more complex than a normal fastening screw. The wide variety of thread types is also necessary, because each of them was developed for a specific purpose and can do something that others cannot do so well. And because threads generally work in the same way despite all the different standards, it is not that difficult to keep track of them.

But there is one type of thread that is a little out of the ordinary. So much so that it may not even be recognizable as a thread at first glance. We are talking about the saw thread. Why it has such a curious geometry, what it can do particularly well and where the saw thread is used due to its special properties - we explain all this and more in the following blog post.

These are the special features of the saw thread

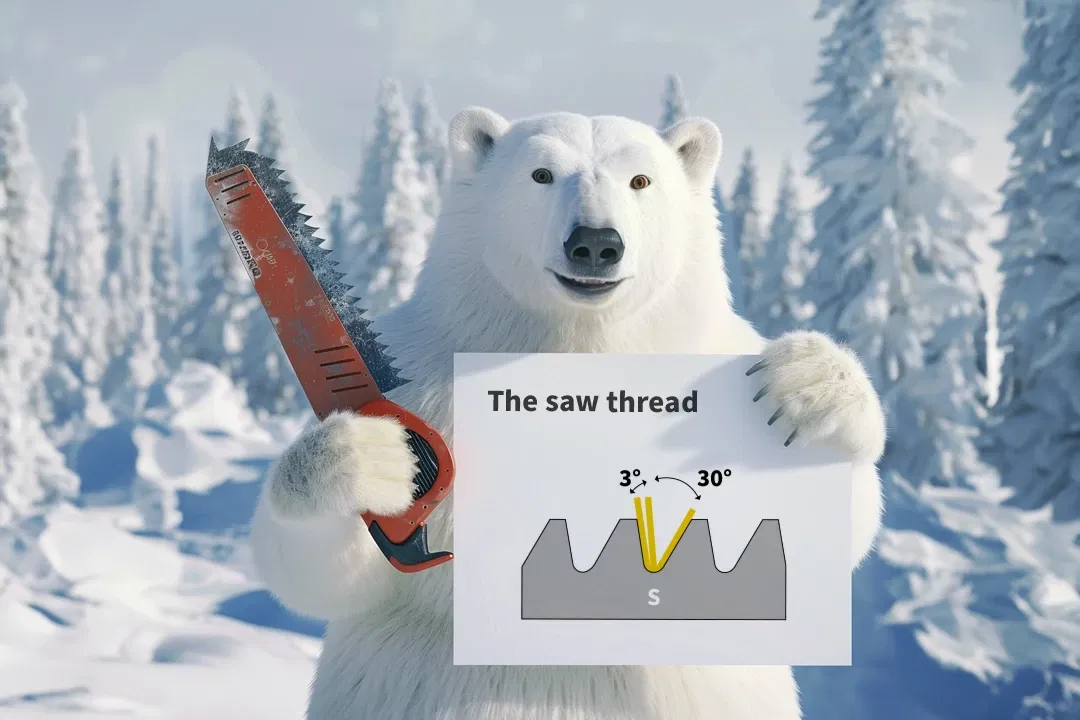

It quickly becomes clear where the saw thread gets its name from when we take a look at the profile. In fact, the threads are reminiscent of the teeth of a saw. But that's the whole reason for the name, because the saw thread can neither saw nor does it have a special connection to saws. So what makes a saw thread special?

The profile of the saw thread is not symmetrical

Whether pointed threads, round threads or trapezoidal threads - despite all the variety, thread profiles usually have one thing in common: they are symmetrical. This principle is completely overturned with the saw thread. In plain language, this means that the angles of the two thread flanks are not identical.

With saw threads, a distinction is made between load-bearing and non-load-bearing flanks

The reason for this form is the fact that, unlike other thread types, saw threads have a load-bearing and a non-load-bearing flank. Accordingly, two different values must be taken into account for the flank angle, namely the angle between the flank and an imaginary line perpendicular to the axis. The flank angle of the saw thread then results from these two values. For the metric saw thread, the angle on the load-bearing flank is 3° and the angle on the non-load-bearing flank is 30°. The flank angle therefore corresponds to 33°. For better illustration, the flank angle of the metric saw thread can also be specified as 30°+3° or as 30°/3°.

Saw threads are designed for one-sided loads

The distinction between load-bearing and non-load-bearing flanks results from the design of the saw thread, which is intended to withstand particularly one-sided loads. The load-bearing flank is almost perpendicular to the axis and can therefore generate an enormous force in the axial direction and offer an extremely high load-bearing capacity. This makes saw threads ideal for transporting loads in one direction as a moving thread.

This is what the saw thread is used for

The saw thread is used wherever high loads act in only one axial direction. Lifting spindles or screw presses, for example, are areas of application for which the saw thread is optimally designed. However, the saw thread can also demonstrate its special properties in completely different areas. For example, saw threads can also be found in applications where clamping force is only required in one direction. Saw threads form the locking mechanism of vices or are also used, for example, to anchor dental implants securely in the jaw. Saw threads are also used in the oil industry, where the one-sided force parallel to the axis has the additional advantage of enabling securely sealing connections.

These types of saw threads are available

Saw threads are available in different variants. The following versions are used particularly frequently:

The metric saw thread

The metric saw thread is also known abroad as the "German saw thread" and is the variant that you will encounter most frequently in this country. The metric saw thread is characterized by its comparatively low flank angle of 33°, with 3° on the load-bearing flank and 30° on the non-load-bearing flank. The metric saw thread is standardized according to DIN 513-1 to DIN 513-3, where it is available in dimensions from 10 mm up to 640 mm. The metric saw thread is marked with the abbreviation S.

Saw thread with 45° flank angle

In addition to the metric saw thread, threads with a 45° flank angle are particularly common. The simplest version has a load-bearing flank that is exactly perpendicular to the axis with a 45° angle on the non-load-bearing flank. However, these dimensions are not optimal for all applications of the saw thread. There is also an American ANSI saw thread in which the 45° angle on the non-load-bearing flank is supplemented by 7° on the load-bearing flank. There is also a thread standard with these dimensions in Great Britain.

Saw thread for plastic containers

A special variant of the saw thread is the saw thread for plastic containers in the packaging industry, which also has its own standard with the number DIN 6063-1. It is designated with the abbreviation KS. The saw thread for plastic containers in the packaging industry has a particularly high angle of 10° on the load-bearing flank, which is supplemented by an angle of 40° on the non-load-bearing flank. Incidentally, there is also a DIN 6063-2 standard for trapezoidal threads for plastic containers. These two standards should not be confused with each other.

Of course, you also need a very special tap for the special saw thread. And where can you find it? In our BAER online store! And while you're here, be sure to take a look at our other threading tools and accessories, which will make your work twice as easy. If you have any questions or problems, our customer service team will be happy to help.