BAER HSSE VAP Hand Tap Finishing (No. 3) M 8 x 1.25 - for Stainless Steel

€10.58*

Prices incl. VAT plus shipping costs

In stock

Express shipping is also possible for this product

BAER HSSE VAP Hand Tap Finishing (No. 3) M 8 x 1.25 - for Stainless Steel

The hand tap finishing tap (No. 3) enables you to cut a finished thread. It is advantageous to shape the thread beforehand with a taper tap (No. 1) or intermediate tap (No. 2) in order to better distribute the cutting power.

The finishing tap (No. 3) can optionally also be used without a pre- or intermediate tap (No. 2) as it already cuts a fully usable thread. However, the short chamfer makes it more difficult to get straight into the hole and the tool life time is reduced compared to using multi-part hand tap sets

Compared to the machine tap, the hand tap has a short shank. This allows you to cut internal thread by hand without jamming and can be operated with tap wrenches, tool ratchets or other holding tools with square drive.

The thread can be cut into a pre-drilled core hole. Due to the short chamfer of the finish tap, it can be used universally for through holes and blind holes.

Dimensions

| Diameter |

8 |

|---|---|

| Nominal diameter in inches |

0,315 |

| Nominal diameter in mm |

8 |

| Pitch |

1,25 |

| Pitch in mm |

1,25 |

| Dimension |

M 8 x 1,25 |

Characteristics

| Product group |

Screw taps |

|---|---|

| Product type |

Hand tap sets |

| Thread standard |

M: Metric ISO standard thread according to DIN 13 |

| Tolerance |

ISO2/6H |

| Direction |

Right |

| Standard |

DIN 352 |

| Tensile strength at room temperature |

up to 1400 N/mm² | 44.5 HRC |

| Material |

HSSE VAP |

6.8 mm

Through hole and blind hole up to 2 x D

Form C straight fluted

2-3 threads

Rarely occurs. Chips remain in flutes.

External cooling and lubrication

HSSE VAP

up to 1400 N/mm² | 44.5 HRC

ISO2/6H

Applications

- Wear resistant steels up to 1400 N/mm²

- High alloy steels

Examples of applications

- M8 bicycle thread for clamping stem shaft and saddle

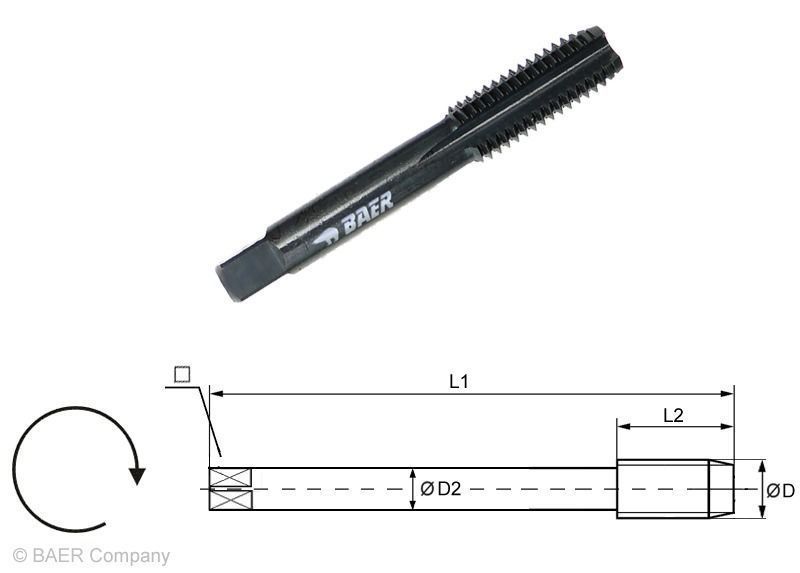

Technical drawing

| D1 |

M 8 x 1,25 |

|---|---|

| D2 |

6 mm |

| L1 |

56 mm |

| L2 |

22 mm |

| Diameter |

8 |

| Square |

4,9 mm |

Application – Sample materials

| Rust / acid-resistant steels | |

|---|---|

| 1.4105 | X 6 CrMo S 17 |

| 1.4305 | X 8 CrNi S 18-9 |

| 1.4301 | X 5 CrNi 18-10 |

| 1.4541 | X 6 CrNiTi 18-10 |

| 1.4057 | X 17 CrNi 16-2 |

| 1.4112 | X90 CrMoV 18 |

| 1.4006 | X 12 Cr 13 |

| Case-hardening steels | |

|---|---|

| 1.0401 | (C15) |

| 1.7016 | 17 CR3 |

| 1.7131 | 16MnCr5 |

| 1.5919 | 15CrNi6 |

| Quenched and tempered steels unalloyed | |

|---|---|

| 1.0402 | C 22 |

| 1.1151 | C22E (Ck 22) |

| 1.0503 | C 45 |

| 1.1191 | C45E (Ck 45) |

| Pure titanium | |

|---|---|

| 3.7035 | Ti 99.4 / Ti Gr.2 |

| 3.7065 | Ti 99.2 / Ti Gr.4 |

| Quenched and tempered steels alloyed | |

|---|---|

| 1.1133 | 20Mn5 |

| 1.5710 | 36NiCr6 |