Why a turnbuckle needs a thread

Sometimes the most obvious solution is the best. The turnbuckle is neither a new invention nor one that relies on particularly complicated mechanisms. And yet the turnbuckle has established itself in numerous areas as an irreplaceable aid for tensioning ropes or cables as required. And which element ensures that the turnbuckle accomplishes this task so effortlessly? The thread, of course. Or to be more precise, two threads that work hand in hand. In this blog post, we take a closer look at how exactly this works and where the turnbuckle is particularly popular.

How does a turnbuckle work?

Although turnbuckles are available in many different designs, the structure is always the same. The heart of the turnbuckle is the body in the form of a double nut. Then there are the two threaded end pieces, which can take on different shapes depending on the type of turnbuckle.

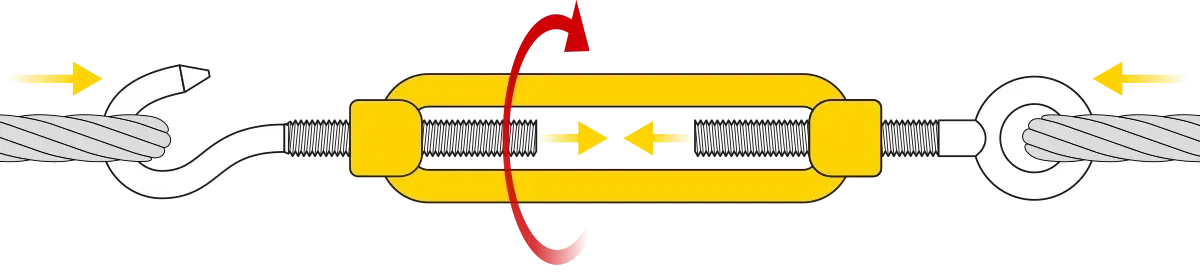

Ropes, cables or straps can be attached to the end pieces of the turnbuckle. If you then turn the central body, the end pieces move towards each other. Thanks to the special design of the turnbuckle, this happens without the end pieces also turning. By turning the turnbuckle open and closed, tension can be created or loosened without the attached ropes or straps twisting.

How exactly you turn the body depends on the size of the turnbuckle and the degree of tension you want to create. With small turnbuckles and low tension, you can simply turn the body with your fingers or use a screwdriver. On the construction site, on the other hand, you may need to use long rods to benefit from the leverage effect.

Which threads are used for turnbuckles?

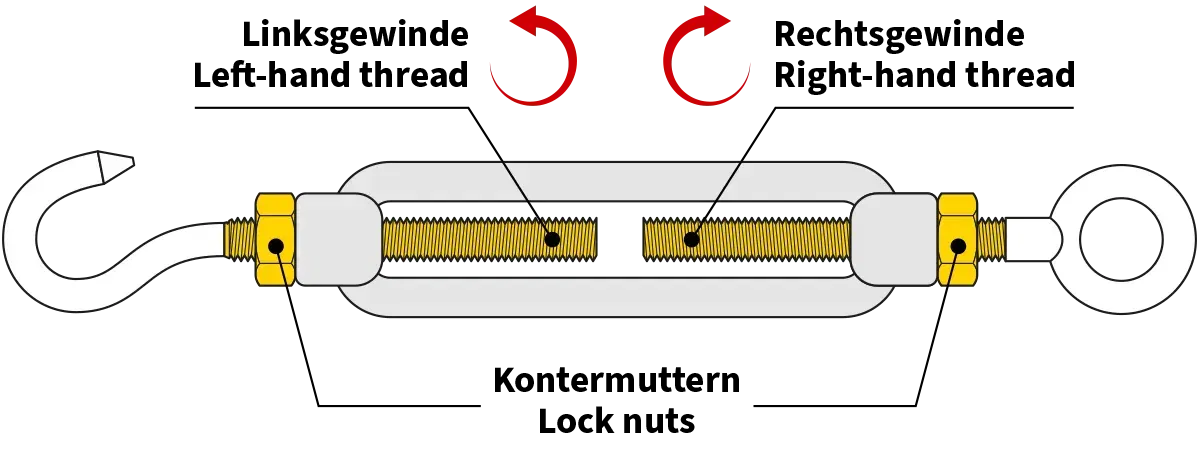

The threads play a decisive role in the turnbuckle. It is important that the two nuts on the body have opposing threads and that one of the end pieces has a left-hand thread and the other a right-hand thread. This is the only way for the crucial mechanism to work. When you turn the body, the end pieces do not move in the same direction but towards each other thanks to the opposing threads. This allows the tension to be adjusted very precisely. For high tensions and applications with vibrations, there is also the option of securing the threads with lock nuts to prevent unintentional loosening.

The load capacity of the turnbuckle depends on the material used and, above all, on the thread size. When purchasing a turnbuckle, you should therefore make sure that the thread diameter is large enough for your purposes. Turnbuckles can be equipped with different types of thread. Turnbuckles with an M thread are standardized according to DIN 1478 or DIN 1480 and are available in a wide range of dimensions.

What types of turnbuckles are there?

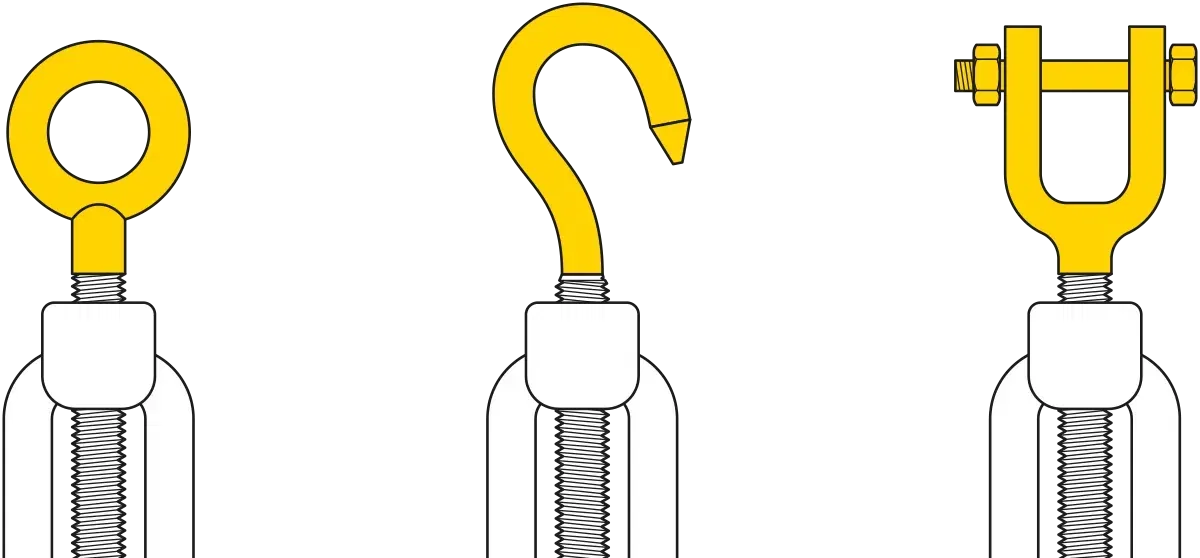

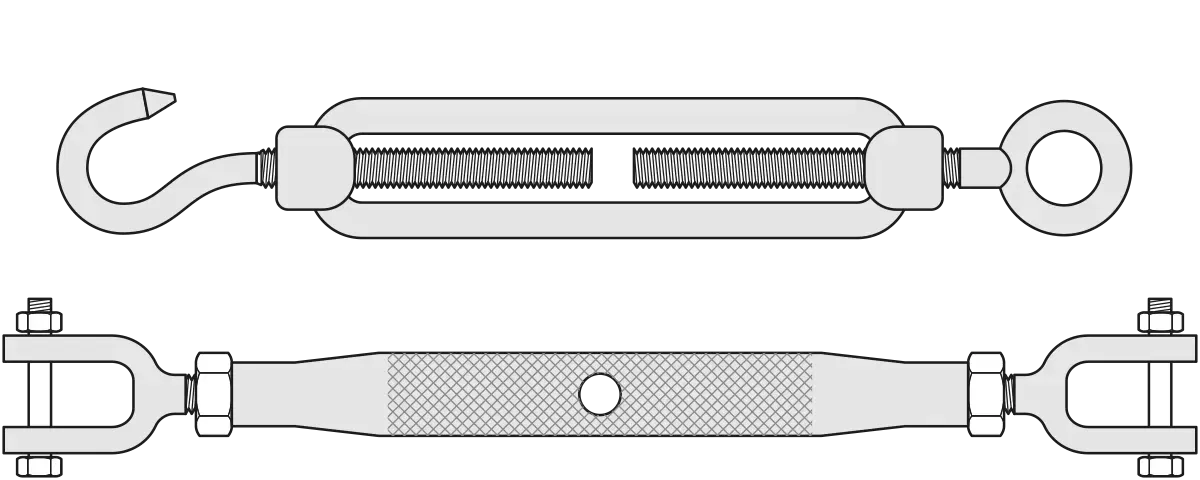

The main difference between turnbuckles is the design of the end pieces. There are various shapes that can be combined with each other in different ways. The most common type is turnbuckles with hooks and eyes. The combination of two hooks or two eyelets works as well as the turnbuckle with a hook on one side and an eyelet on the other.

There is also a design with a fork. Here, the end pieces run out in a U-shape, which can be closed at the upper end with a bolt and matching nut. Shroud tensioners, which are very frequently used in sailing, also fall into this category.

The body of the turnbuckle can also be designed differently. The open form is often used, in which the two nuts are connected to each other by two rods attached to the side. However, there is also a closed form in which the body resembles a tubular body. This design is somewhat narrower and also offers a certain amount of protection for the internal threads

A turnbuckle is used in these areas

Turnbuckles are used wherever cables, ropes, straps or cables need to be kept under tension. In some areas, however, they have become particularly popular.

Turnbuckles for sailing

Shroud turnbuckles are standard equipment in sailing and are used to precisely adjust the tension of the cordage. Shroud turnbuckles are turnbuckles with a fork, but they are also a product category in their own right and are often made of stainless steel due to their place of use.

Turnbuckles in the construction industry

In the construction industry, turnbuckles are often used to temporarily fix components in one position. The term clamping screw is often used in this context. The clamping screw allows the components to be perfectly aligned before they are then permanently screwed together. After permanent fixing, the turnbuckle is usually removed again.

Another common application for turnbuckles in the construction industry is bridges, whose steel cables need to be kept under permanent tension. Turnbuckles are also ideal for any type of temporary structure, such as in trade fair construction. Turnbuckles are also popular for fences.

Turnbuckles in mechanical engineering

Turnbuckles are also used in mechanical engineering, for example to tension chains or belts. Turnbuckle devices can also be used on machines to adjust play, stroke or spring force.

Turnbuckles in sport and the entertainment industry

Turnbuckles are also often used outside of heavy machinery, for example to keep the rope boundaries of boxing rings taut. And theater performances, concerts or film shoots would also be inconceivable without turnbuckles. They are an essential part of any stage equipment and help with the positioning of spotlights and other elements.

You can also find all kinds of threading tools in our BAER online store. Why not take a look? And if you have any questions or problems, the friendly BAER customer service team will be happy to help.