Festsitzende Gewinde lösen – So klappt es auch bei Ihnen

Fastening threads are meant to hold tight; that’s a crucial part of their job. After all, these threads are used with screws, bolts, and the like to keep components together. But as with everything in life, it’s all about the right balance. If the screw is so tight that it can’t be loosened anymore, you’re often facing a serious problem.

You’ve surely encountered this situation: You want to unscrew a bolt after a long time, whether to repair your motorcycle or disassemble furniture for an upcoming move. You position the screwdriver, but nothing happens. Stuck screws are a major nuisance and can turn even minor repair work into a big hassle. But don’t worry – we won’t leave you alone with this issue. Here are our tips for loosening jammed threads and stuck screws.

Finding the Cause and Prevention: Why Won’t the Screw Move?

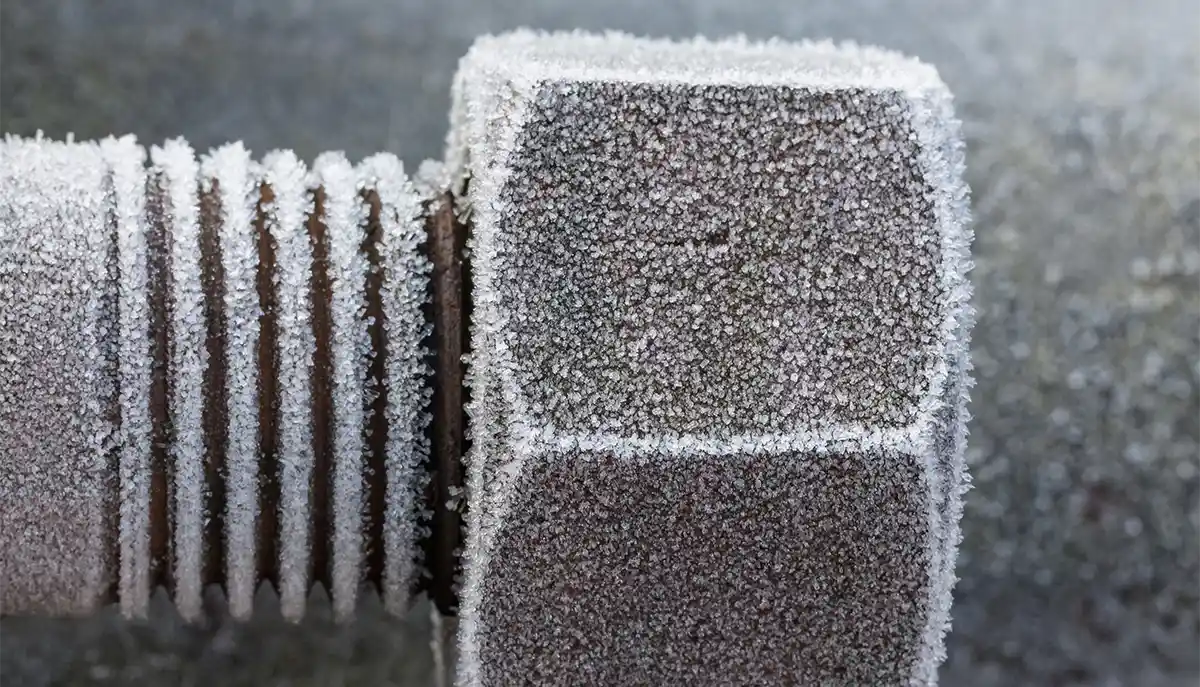

As always, prevention is better than cure. Why does it happen that screws can’t be loosened anymore, and is there a way to prevent it? Often it’s rust or other deposits in or on the thread that prevent the connection from coming apart. You can prevent this by paying attention to dryness and cleanliness during assembly. However, that’s not always easy to do, and many deposits form over time without your control.

You have more control over mechanical factors. If the thread is not properly cut or you tighten the screw too much, the threads can get damaged or jammed, making it impossible to loosen the screw. So, care and a delicate touch will really pay off here.

Loosening Stuck Screws: Your Options

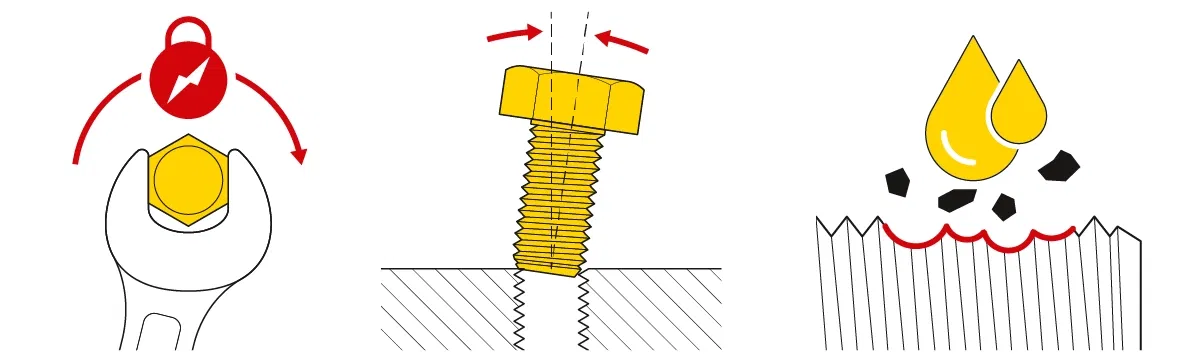

The first instinct when trying to loosen stuck or rusted screws is often to use brute force. But that usually causes even more damage. So always proceed gently and try the mild methods first before resorting to more forceful ones.

Loosening Screws with Tools

First, try using different tools to loosen the screw. If the screw head is protruding, a pair of pliers might help. This is especially useful if the screw slot is stripped and you can’t apply enough force otherwise.

Gentle taps with a hammer are a good way to break crusts inside the thread. The slight movements can crack these buildups and allow the screw to turn again. Be very careful with this method and, if necessary, place a piece of fabric underneath to protect the component from damage.

A more aggressive method, which should only be used on robust parts, is striking the screw with a hammer and chisel or center punch. First, notch the screw, then position the chisel or punch in the notch. Further hammer blows can then rotate the screw in the loosening direction.

Loosening Screws with Heat or Cold

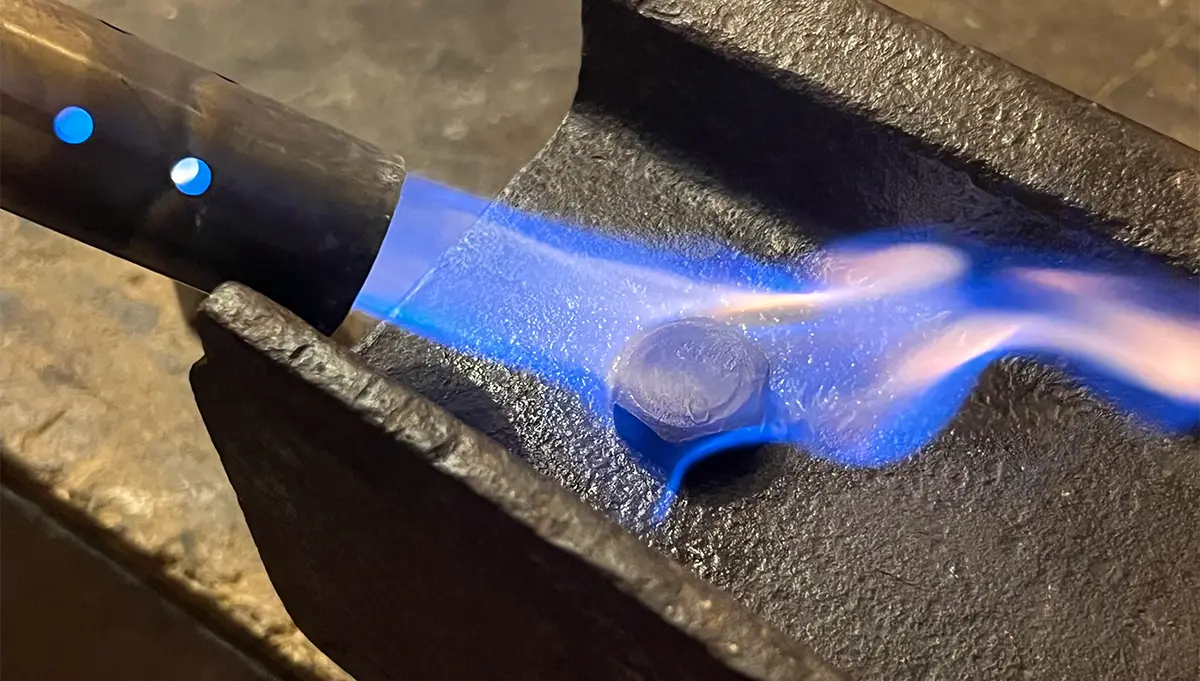

To loosen jammed or encrusted threads, there needs to be movement in the thread. And that can be achieved not just mechanically. Depending on the material, heat and cold can cause the material to expand or contract, which can free the thread. Cold can be applied precisely using freezing spray from the hardware store. Heat is a bit trickier. You can use a hot air gun or the flame of a gas burner.

Especially when using heat – safety always comes first. Never use an open flame in confined spaces or where you can’t guarantee adequate fire protection measures. When in doubt, a stuck screw is still a smaller problem than a burned-down workshop!

Loosening Screws with Chemical Aids

And finally, there’s the option of loosening screws with the help of chemicals. Rust dissolver spray or a special oil like penetrating oil are excellent for solving the issue gently and with minimal effort. Be patient and let the agent soak in for a while – ideally for several hours or overnight. Then try to move the screw with a screwdriver. For stubborn cases, repeat the process.

What to Do If the Thread Gets Damaged While Loosening?

Just because the screw is out doesn’t mean the problem is solved. You should always inspect both the internal and external threads to check whether damage has occurred or may have even caused the problem in the first place. A broken screw can be replaced easily, but what if the thread on an expensive component is damaged? There are solutions for that too.

To remove rust and dirt, you can re-cut the thread using the correct tap or treat it with a thread restorer. For more serious damage, a thread repair may be necessary. This involves using special inserts that are installed into the damaged thread. That way, you can fully restore the thread’s functionality without having to replace the entire part.

You’ll find thread tools and accessories of all kinds in our BAER online shop. We also offer effective solutions for thread repair. Take a look and see for yourself. If you have any further questions, our customer service is happy to assist you by phone or via our contact form.