Bienvenue sur le blog de BAER

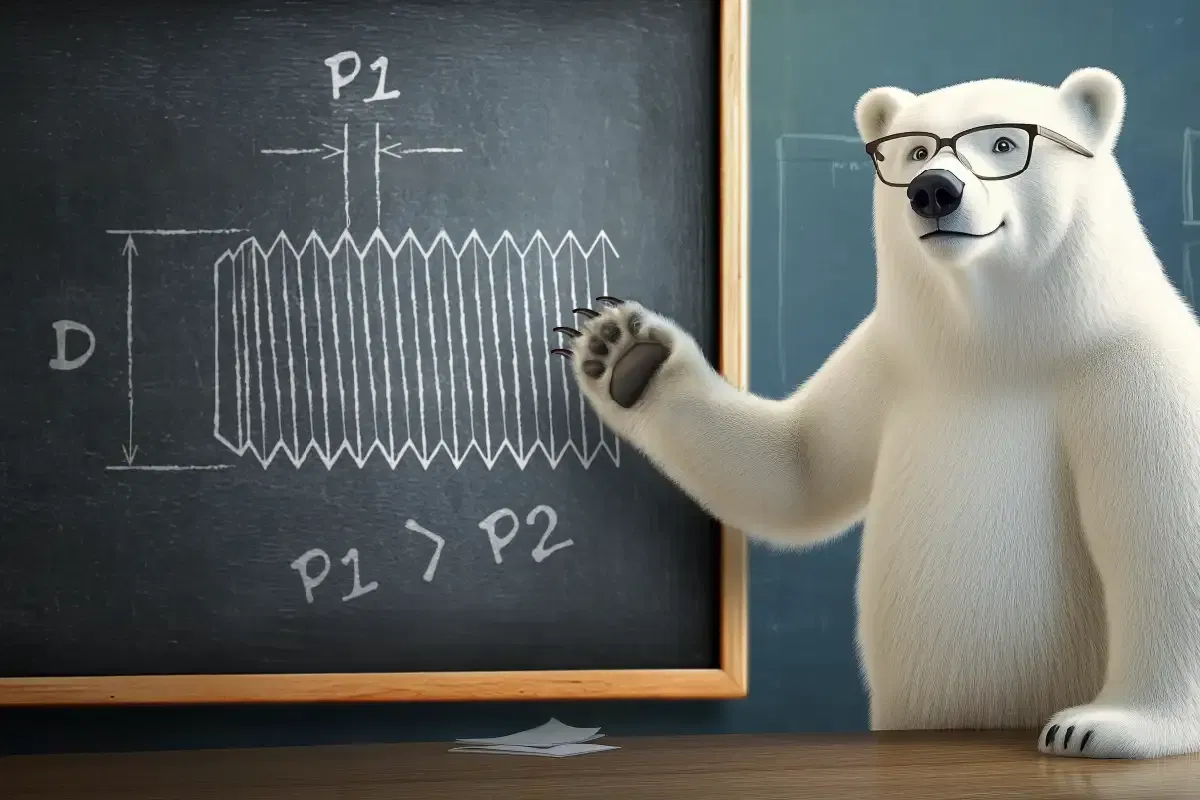

Bienvenue sur notre blog, le lieu de rencontre par excellence de tous ceux qui s'intéressent aux filetages, aux tarauds, aux inserts filetés et à la réparation des filets. Nous plongeons dans le monde du travail de précision et expliquons pourquoi les outils de filetage sont indispensables dans l'industrie manufacturière moderne.

Notre blog propose non seulement des connaissances de base sur les filetages et leur application, mais aussi des techniques et des méthodes avancées de coupe et de réparation des filets. Apprenez à améliorer vos projets grâce à des inserts de filetage, des tarauds et des mandrins de perçage de haute qualité. Nous présentons les dernières innovations et les meilleures pratiques afin d'élargir vos compétences et votre compréhension de ces outils essentiels.

Des guides détaillés sur la façon de choisir les bons outils aux conseils d'experts sur la façon de les utiliser efficacement, notre blog est un trésor pour tous ceux qui travaillent dans l'industrie manufacturière, les amateurs de bricolage ou simplement ceux qui s'intéressent à la technologie du filetage. Rejoignez notre communauté et restez au courant des dernières tendances et évolutions dans le monde du filetage. Nous sommes impatients de partager nos connaissances avec vous et de repousser ensemble les limites de la technologie du filetage.

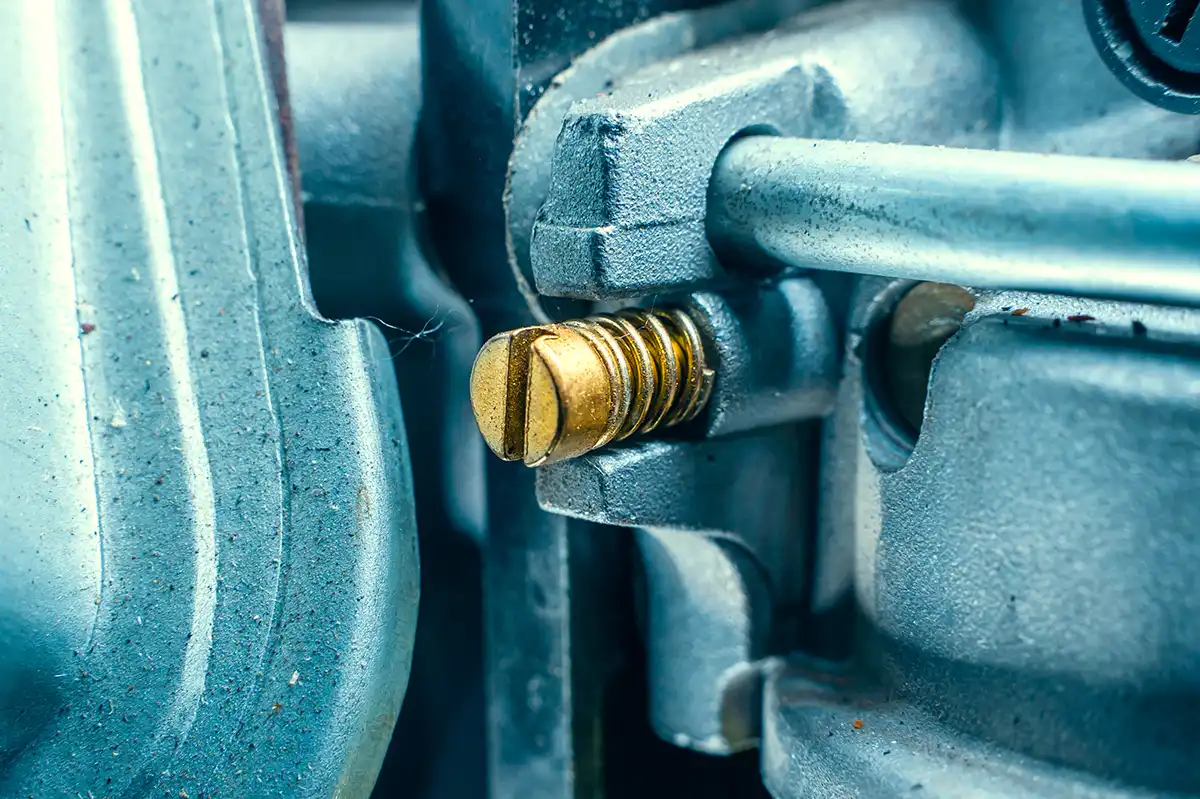

How do you actually know if your thread has been successfully cut? In many cases, like small repairs or DIY projects, simply testing the thread is enough. If the screw or bolt moves easily without jamming or seizing and can be fully screwed in and out again, you can consider your work a success.