Test

We are all familiar with threads as a safe and simple solution for connecting two components together. As craftsmen and DIY enthusiasts, we use them every day in the form of screws and nuts. You have probably also heard of movement threads. But threads can actually be used much more flexibly than you may have realized. Did you know that these geometric shapes are also used to transport a wide variety of materials?

The idea is not only ingenious, but also very old. Thousands of years ago, people were already using such constructions to transport water. And it has stood the test of time, because even in this day and age with all its modern possibilities, there are still conveyor systems based on this ancient principle. So let's take a look at what lies behind the threads used to transport materials. To do so, we will shed light on the historical origins as well as the question of where the basic idea is still used today.

What does Archimedes have to do with it?

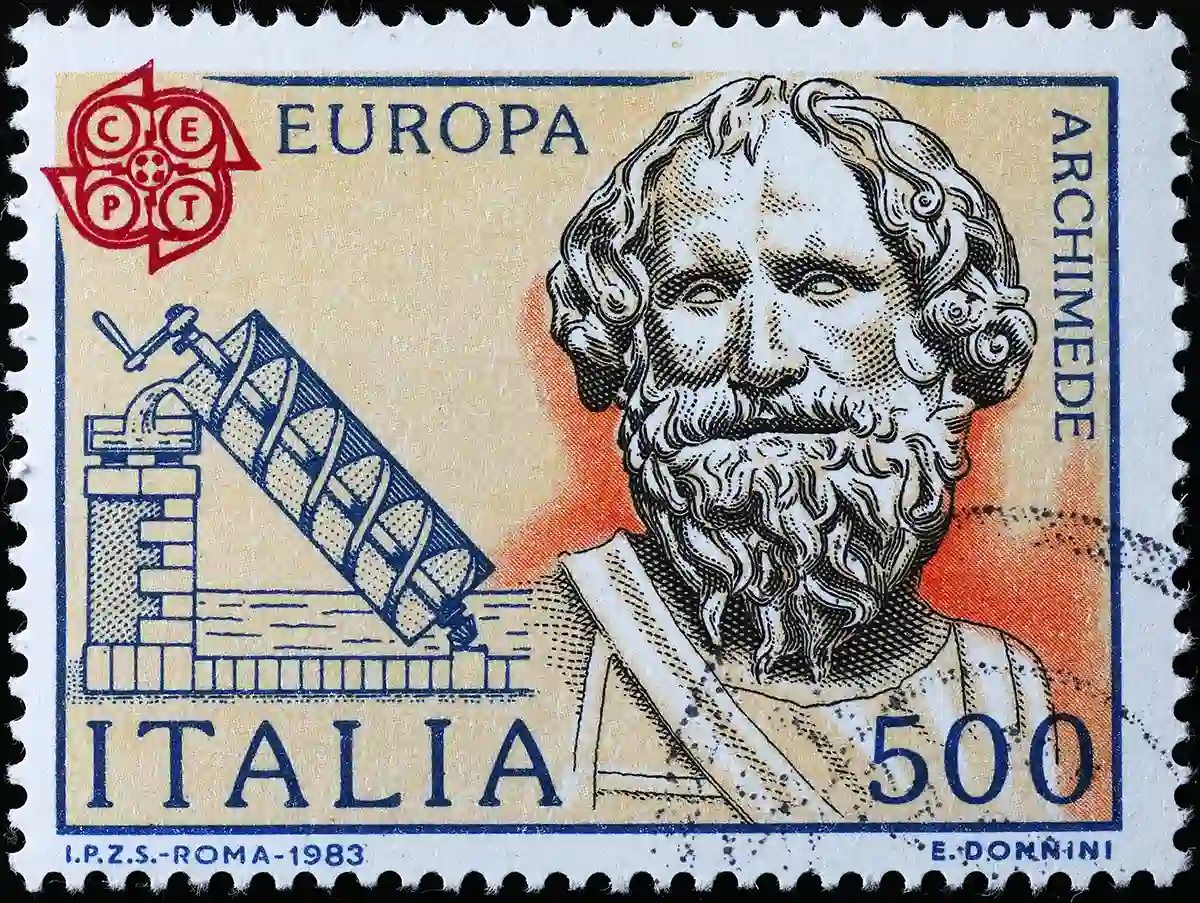

It all started with Archimedes - but that's hardly surprising. After all, the Greek mathematician and inventor from the 3rd century BC is generally regarded as a universal genius and laid the foundations for many a breakthrough in the field of physics and mathematics. However, we do not know for sure whether he really came up with the idea of transporting water using threads or whether he was simply writing down an already known principle.

In any case, Archimedes plays a decisive role in the tradition of construction, which is why the best-known realization still bears his name today: Archimedes' screw.

Screw pumps, screws and spirals - how does material transportation by thread work?

The Archimedean screw is the standard example of a conveyor system that transports material by means of a thread and many of the modern variants are very closely based on this principle. So let's first take a look at how this basic principle has worked since ancient times. Since then, of course, there have been many further developments and modifications, especially in the form of pumps such as the screw pump or worm pump.

How an Archimedean screw works

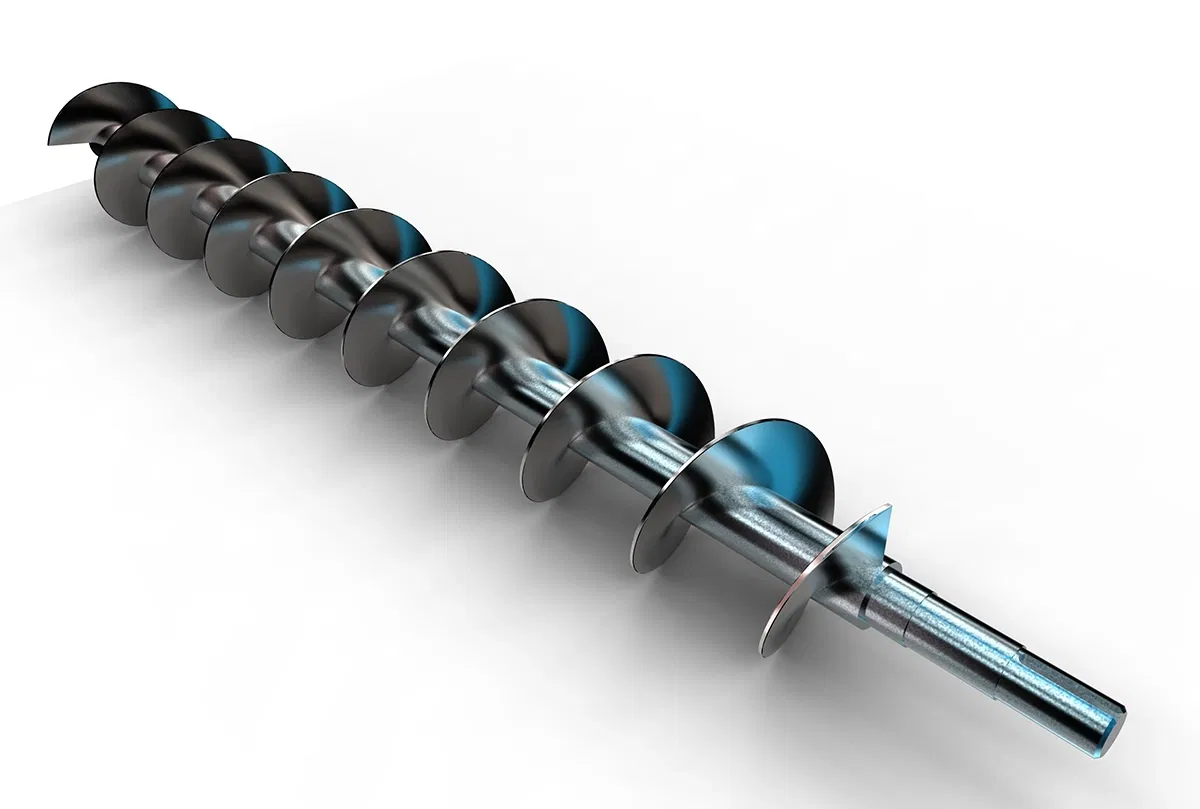

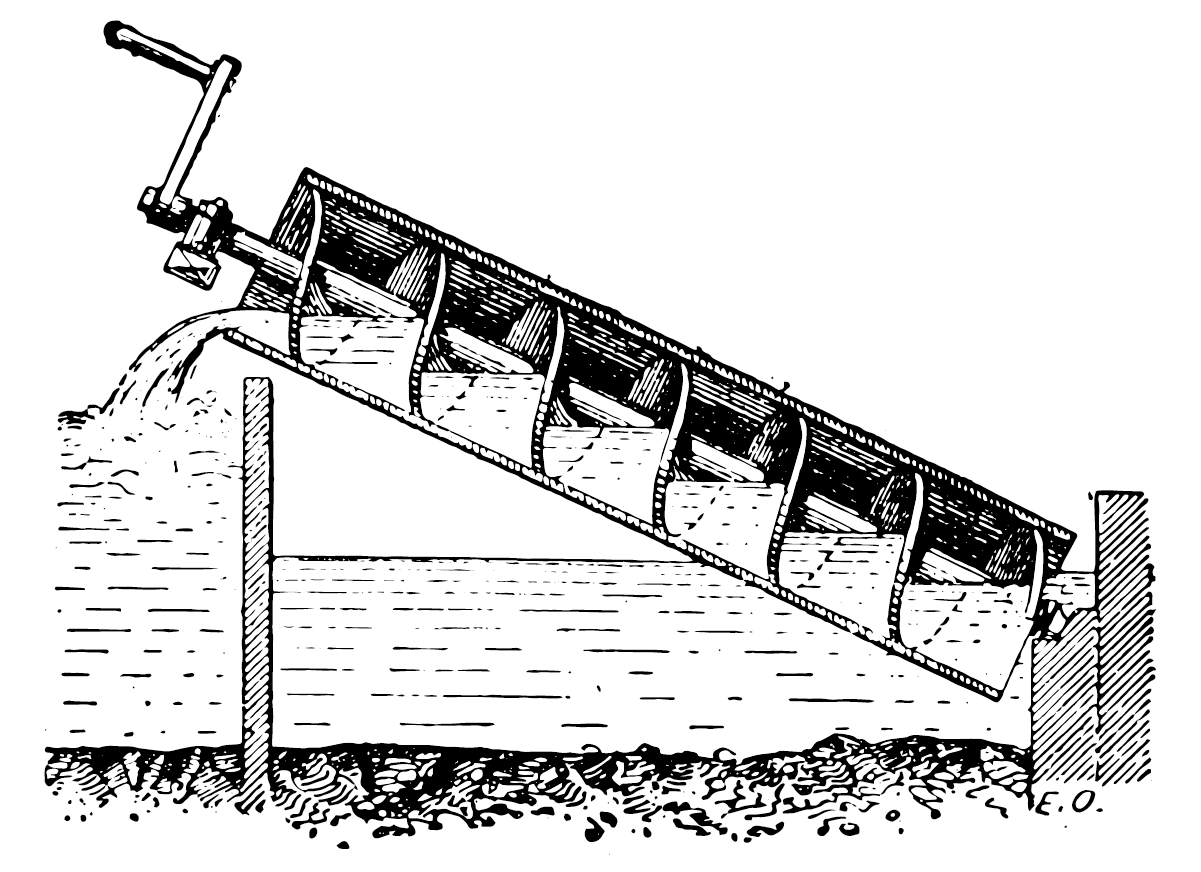

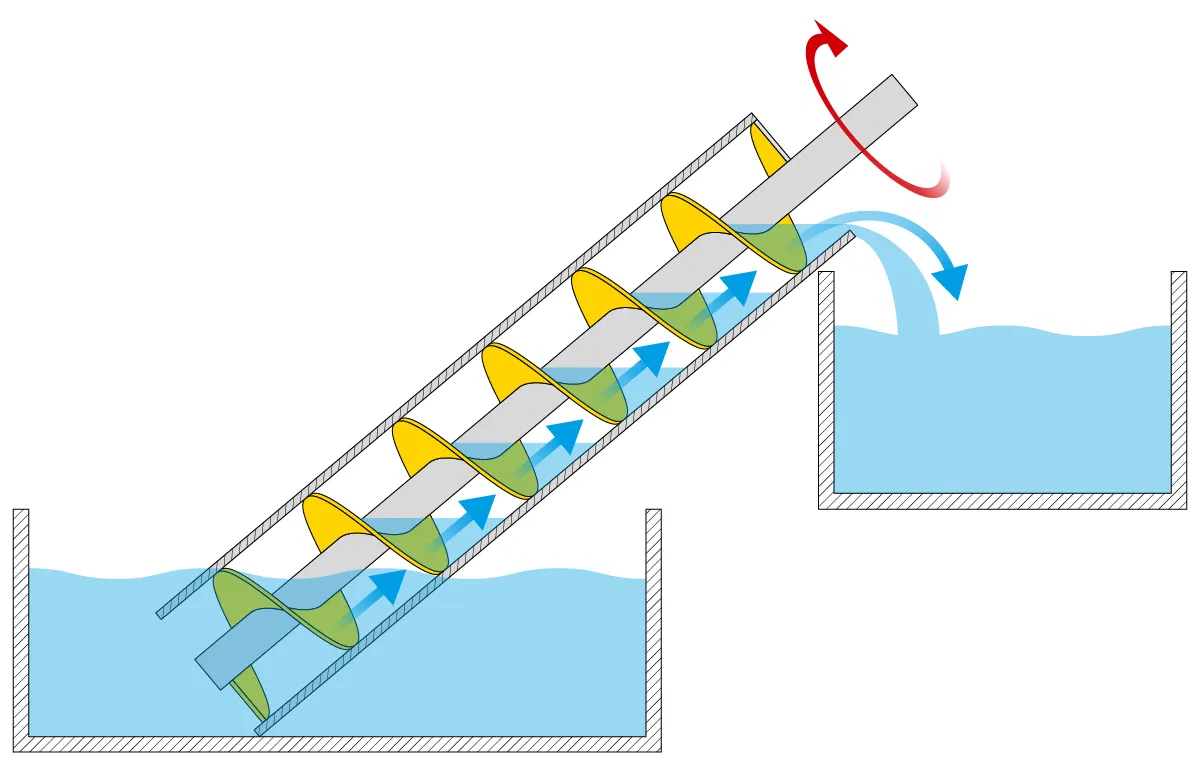

The classic Archimedean screw consists of two parts: a trough or tube and a threaded rod. The thread is characterized by very wide thread valleys, which create chambers in which the liquid to be transported can be accommodated. This rod now rotates within the pipe. In the past, the rotation was generated by simple means, such as a windmill or muscle power. Nowadays, the mechanism can be driven by a motor.

The rotary motion moves the liquid upwards to the outlet of the pipe until it emerges at the top. Historic screw pumps were usually operated with an inclination of 37° to 45° and could overcome delivery heads of up to 6 meters. And they were efficient to operate even with antique means, as no watertight seal is required between the thread and the pipe.

Water is not the only material that can be conveyed in this way. Any type of powder or granular material can also be moved using the same principle.

Water screws: The reverse principle of Archimedes' screw

And the mechanism can also be used in the opposite direction to this day. Hydropower screws generate electricity in modern hydropower plants. Here, it is not the screw that moves the water upwards, but the other way round: water flows downwards, generating rotation, which in turn drives a generator.

The screw pump - same principle?

At first glance, you might think that an eccentric screw pump works in the same way as an Archimedean screw. Here too, a threaded rod rotates in a pipe, whereby the thread is usually realized as a round thread. However, the movement of the pumped medium in these systems is achieved by displacement and is therefore based on a different physical principle.

What are the advantages of such a system?

Use since ancient times right up to the 21st century - that's quite a success story. The question naturally arises as to what makes the Archimedean screw principle and designs based on it so useful that it is still in use today. This is mainly due to the fact that such conveyor systems are both robust and flexible.

They can cope well when the flow rate fluctuates or the viscosity of the material is not always uniform. The Archimedean screw can also show its strengths in areas where liquids have to be transported that are sometimes interspersed with solids.

This is where threads are used to convey materials

Did you already have a vivid image in mind when you heard the phrase “liquids interspersed with solids”? Exactly, sewage treatment plants are a prime example of applications in which conveying systems based on the Archimedean screw principle have proven their worth.

But there are even more appetizing examples. Conveying systems based on this principle are also used on combine harvesters, in grain elevators or in concrete mixers. The progressing cavity pump in particular also has numerous applications in the food industry, for example for conveying ingredients in pasta production or as the basis for various transport systems in breweries or in viticulture.

And you may have seen a thread for transporting materials in action at the last major event with a buffet. It is precisely this mechanism in the chocolate fountain that ensures that supplies can keep flowing in from above.

Unfortunately, you won't find chocolate fountains in our online store, but it's still worth taking a look! If you are looking for threading tools and everything else you need for thread processing, you are guaranteed to find what you are looking for here! And if you have any questions or concerns, our customer service team is always on hand to help.