Accessories for thread cutting: What you really need

You may be familiar with this phenomenon: you just want to buy an urgently needed tool, but while shopping an exciting item catches your eye and your shopping cart is full of products that you don't actually need. The abundance of options can sometimes obscure your view of which tools and aids you actually need for your work.

Today we would like to shed some light on the subject and help you to make more targeted purchases in the future. To this end, we have prepared a comprehensive overview of all the items you might need for thread machining in addition to the tap itself.

Thread cutting by hand: actuating tools and co.

If you have decided to cut your thread by hand, you will need the right tap for an internal thread or a die for an external thread. A tool holder is required so that you can use these tools.

Tool ratchets and tap wrenches

Taps for cutting a thread by hand can be inserted into a tool ratchet or a tap wrench. The tool ratchet has a square chuck and can be used with taps of different dimensions.

A tap wrench holds the tap - or any other tool with a square shank - in place between two clamping jaws. It requires a little more space due to the long handles, but you can also work on larger diameters thanks to the higher torque that can be achieved.

For deep internal threads, the reach of your tool can be further increased with an extension. This is simply positioned between the tap and the holding tool.

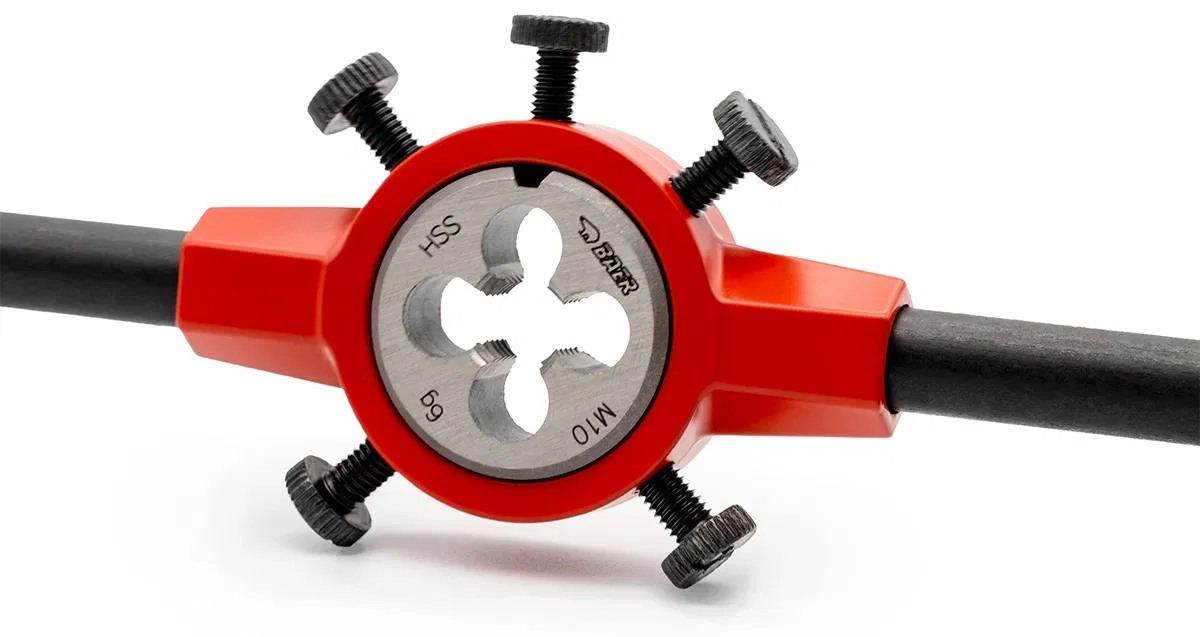

Die holders and die guides

You use cutting dies by clamping them in a die holder. The fastening screws hold it in place and the long handles support efficient power transmission and straight alignment of the tool.

If you have problems with the plumb alignment of the die, a die guide can be helpful. This is inserted into the holder in front of the die and slides along the bolt during work, holding the tool securely in the correct position.

Before thread cutting

Before you can start cutting a thread, some preliminary work must be done. You will also need various tools for this.

Twist drills and step drills

You can only ever cut an internal thread in a finished hole - unless you use a combination machine tap that can create its own core hole. You will therefore always need a twist drill in the right size. You can also use a step drill for through holes in sheet metal or similar.

The advantage of these tools is that they can be used for many more applications than just preparing a core hole. A set of high-quality twist drills should therefore always be in your toolbox.

Countersink

Countersinks are always optional accessories, but their use is highly recommended. By countersinking the edge of your core hole, you not only create space for the head of a countersunk screw, you also create a clean and burr-free finish. Countersinking also makes the subsequent tapping process easier.

Lubricant

Lubricant in the form of oil or cutting paste should always be used in sufficient quantities when cutting threads. It makes your work much easier, helps to remove chips and leaves a smooth surface. Apply a sufficient amount of cutting paste to the cutting edges of your tool before you start working.

Maintaining and checking threads and taps

But tapping is not the end of the story. Tools and threads must be kept in good condition and checked for proper functioning at regular intervals. You can also get support for this.

Threaded inserts

To repair worn or damaged threads, you can use thread inserts in various designs. Whether as wire thread inserts or threaded bushes - these useful products help you to reduce waste.

To reinforce a thread in this way, you also need a twist drill and a countersink, and a suitable tap for wire thread inserts. Special installation tools are also required for installation. If you want to purchase all the items you need conveniently as a set, then thread repair kits are a good choice.

Thread restorer

Sometimes threads are just a little dirty or rusted and can be easily repaired. In such cases, you can use a thread restorer for internal or external threads. In this way, you can quickly, flexibly and safely remove residue from the threads and restore the original function.

Thread gauges

Even the best tap will show signs of wear sooner or later. At the latest when these become so noticeable that the threads no longer meet the tolerances of the DIN specification, it is time to replace or regrind the tool.

In order not to miss this point, you can check your cut threads for gauge accuracy. This is a simple and above all clear way to ensure that your workpiece meets all requirements.

Conclusion: Which accessories do you need?

So these are all the tools you can use for thread cutting. But which of them are essential, which are optional and which are a nice extra?

You need holding tools for manual tapping, otherwise you won't get very far. So you have no other choice here. You can't do without core drilling either, so twist drills are also a must. You should also not work without lubricant.

Countersinks make the work easier and optimize the result, but are dispensable in case of doubt. You are flexible when it comes to thread maintenance - here you decide how much effort you want to put in. The use of thread gauges is only standard in an industrial environment.

Last but not least, you should of course make sure that all tools and accessories are of high quality and reliable. And we are happy to be the strong BAER partner at your side. Click through our online store to find everything you need for thread machining. And our customer service is always available to answer your questions and concerns.