Buying Thread Gauges: When Is It Worth It?

How do you actually know if your thread has been successfully cut? In many cases, like small repairs or DIY projects, simply testing the thread is enough. If the screw or bolt moves easily without jamming or seizing and can be fully screwed in and out again, you can consider your work a success.

Things get a bit more complicated in industry, where components must be produced according to standards. For legal reasons alone, it is essential to regularly check the compliance of a thread. This is where a thread gauge comes into play. What exactly that is, and whether purchasing a thread gauge might be worthwhile for you as well, you’ll find out in this blog post.

Inspection Tools for Threads: Basics of Measurement Technology

Inspection, measurement, gauging – these terms are often used imprecisely and many people think they are interchangeable. However, each term has a clear definition. Once you understand the difference between measuring and gauging, it becomes much easier to see why thread gauges are needed – and why a caliper is no proper substitute.

The Difference Between Measuring and Gauging

Measuring is easy to explain. As a DIYer or craftsman, you probably do it every day using a folding rule, a tape measure, or a caliper. No matter what you measure, the result matters: a numerical value and a unit. A board is 120 cm long? That’s the result of a measurement.

Gauging, on the other hand, does not produce a specific value. Instead, an actual condition is compared to a target condition, and the outcome is a judgment. Is the component within tolerance or is it scrap? The exact dimensions don't matter as long as they lie within the specified tolerances.

Why Thread Gauges Are Useful

To determine this for a thread, you need thread gauges – and the correct ones. Thread type and size as well as the tolerance class must match the required target values, otherwise the system won't work. Once everything fits, gauging is extremely simple, and measurement or transfer errors are virtually eliminated.

Thread gauges are standardized and thus also ensure legal compliance. In professional environments, they should be used regularly to check whether tools are still performing flawlessly or need to be replaced. In private use, thread gauges are great if you want to be absolutely certain that your threads are within the dimensions defined by the tool's tolerance class.

Internal and External Thread Gauges: Gauging Every Thread

There is a wide range of thread gauges for every thread type, such as metric threads. You will also need different gauges for external and internal threads. For an extra measure of accuracy, you can even have your gauges calibrated.

Gauging Internal Threads with a Plug Gauge

Thread gauges for internal threads are called limit plug gauges. You will always need two: one to check acceptance and one to check rejection. They are called a go gauge and a no-go gauge. For threads up to 40 mm in diameter, both gauges are usually mounted on a common handle, called a limit plug gauge.

Gauging External Threads with a Ring Gauge

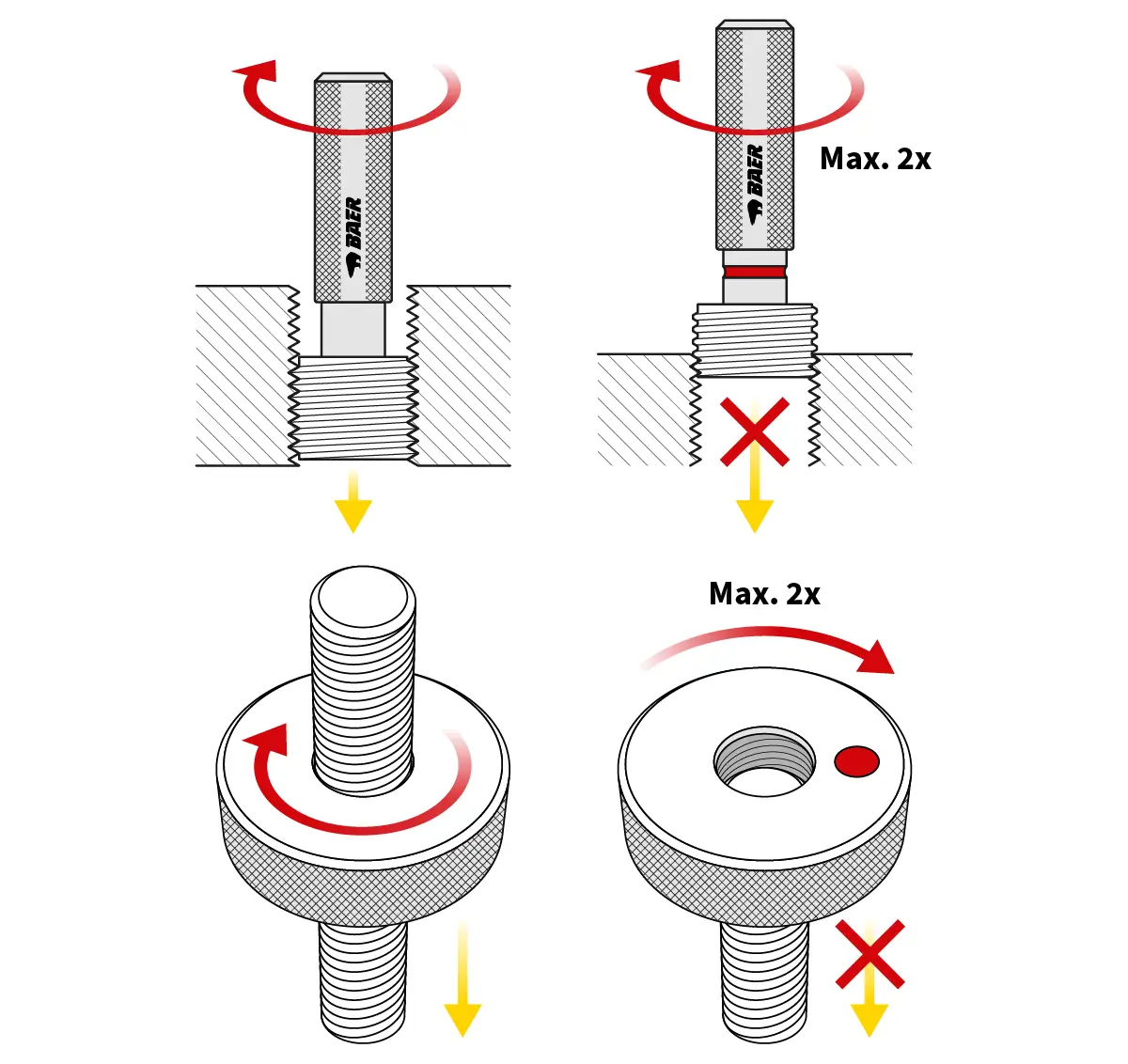

External threads are checked with a ring gauge. Again, there are two versions: a go ring gauge and a no-go ring gauge. Unlike plug gauges for internal threads, external thread gauges are always two separate rings.

How Thread Gauging Works

Plug gauges are screwed a short way into the internal thread, while ring gauges are screwed onto the external thread. If this can be done effortlessly up to a specified depth, the gauging is successful. If the thread fails the gauging test and cannot be reworked, it is considered scrap.

To achieve accurate results, it’s important that the threads are clean and dry, and that the ambient temperature is around 20°C. After all, the thread gauge must detect even the slightest deviations, and materials can expand or contract with temperature changes. Additionally, you should always use the thread gauge manually and with as little force as possible, as they are designed for hand use only.

Modern Methods: Analog or Digital Thread Measurement?

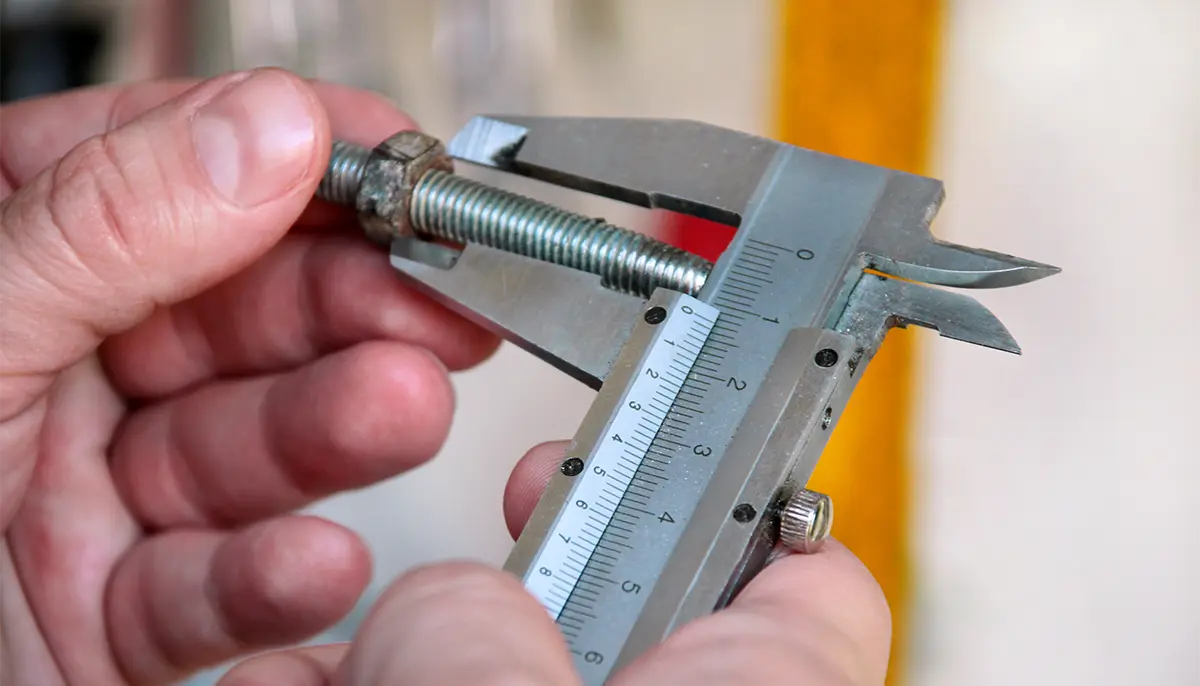

Of course, there are also methods to measure a thread that can be very helpful for both private and professional use. A useful tool here is the caliper, which you can use to determine the nominal diameter of a thread. Calipers are now also available in digital versions, where the measurement is conveniently displayed on a screen. This modern feature helps avoid errors, especially since reading analog calipers with sliding scales can be tricky – particularly for beginners.

In our BAER Online Shop, we offer a wide variety of thread gauges and many other products for you. As a manufacturer of threading tools with decades of experience, we provide not only first-class quality at a fair price but also fast delivery directly to your door.