Checking threads: External and internal threads

You should always be able to rely on a thread. It must be precisely cut and work seamlessly. And of course, it should have the exact dimensions you expect; otherwise, components won't fit together in the end, and you would have wasted a lot of time and effort.

To avoid this, regularly checking threads has become standard practice. Here's the rule: A manufacturer is responsible for ensuring that the threads they deliver have an actual dimension that lies within specified limits and tolerances. Conversely, a customer cannot complain if it's found during the thread inspection that these limits have been adhered to.

Checking threads is thus a crucial process with potential legal implications. Whether you're a DIY enthusiast or especially a professional craftsman, you should at least have a basic understanding of what's involved in this process and how it can be legally secured. That's why today, we're diving deeper into this topic.

Why you should check threads

The answer to this question depends somewhat on your role. If you're a craftsman or a manufacturer of components with threads, you can't avoid a thorough thread inspection. Even the highest-quality tools wear out over time, or mistakes and mix-ups happen. This can lead to the threads you produce silently falling out of the tolerance range. This can have extensive consequences. Your customers not only expect flawless threads and don't need to accept defective workpieces - which can lead to financial losses - but as a company, you also have a reputation to uphold. You wouldn't want your name consistently associated with too large or too small threads.

But from a consumer perspective, it makes sense to check the threads too. After all, you want to ensure that you've received the right threads. Or you may want to verify whether your self-cut threads are within the tolerance range or if you need to replace your tool.

Checking threads with thread gauges

Checking threads is essential, that much is clear. But how do you properly perform a reliable thread inspection? This can be accomplished using the right testing tools. To be sure, you should rely on thread gauges. These are standardized according to DIN ISO 1502 and provide decisive results in disputes.

Gauging threads differs from other testing methods, like measuring, primarily in the type of results obtained. When measuring, a measurement value is obtained, like measuring a distance, resulting in a numerical value. With gauging, however, you determine if the thread is good or rejected. This has several advantages.

During measurement, transmission errors can occur at several stages. The value must be read correctly during thread inspection, then noted down correctly. The value must then be interpreted correctly, where errors or inaccuracies can easily distort the result.

With gauging, on the other hand, the risk of user error is minimized since the approach and interpretation of the results are much less error-prone. Measuring might be faster and more convenient for ongoing thread checks. However, gauging is the safer option and should be done at least on a sample basis.

Practical thread checking

So, we now know that we should perform our thread inspection using gauges for clear and secure results. But how exactly does it work? Specialized testing tools, known as thread gauges, are available for this process. These are straightforward to use and can be easily employed by anyone. Ensure that the thread to be tested is clean and dry and that both the thread gauge and the workpiece are at room temperature.

Checking internal threads

Testing tools for checking internal threads are called thread plug gauges. The application of the thread plug gauge pin is simple: for easy handling, the testing tools are mounted on a handle. Unlike screw taps, thread plug gauges don't have a chamfer so they can gauge from the start.

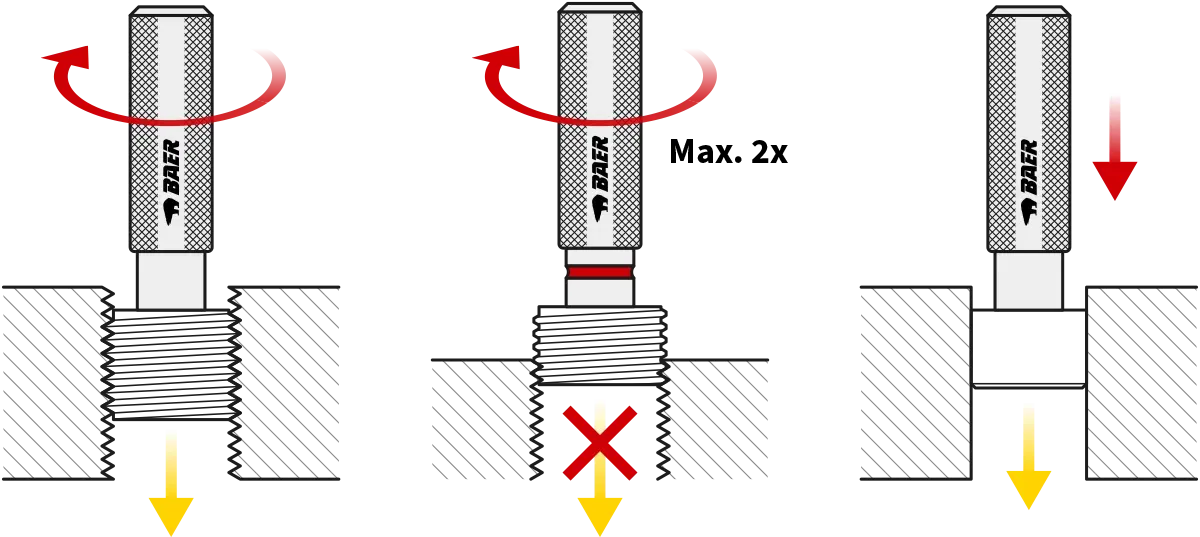

Go thread plug gauge

The Go thread plug gauge checks the smallest diameter of the thread flanks and thread outer diameter, as well as form deviations in the thread, such as pitch or profile. To check the thread, the Go thread plug gauge must be screwed into the thread by hand without any force and must be completely screwed in.

No-Go thread plug gauge

The No-Go thread plug gauge , marked with a red ring, checks if the thread flank diameter exceeds the prescribed maximum size. It's also manually screwed into the thread but should not be screwed in more than two turns.

Limit thread plug gauge

For thread diameters under 40 mm, both the Go and No-Go thread plug gauge are mounted on one handle during thread inspection. This testing tool is then called a limit thread plug gauge. The No-Go side is again marked with a red ring, and its application is similar to the individual testing tools.

Plain gauges for internal thread core diameter

The internal thread core diameter can be tested using a cylindrical plain plug gauge. Again, there's a Go and a No-Go gauge pin.

Checking external threads

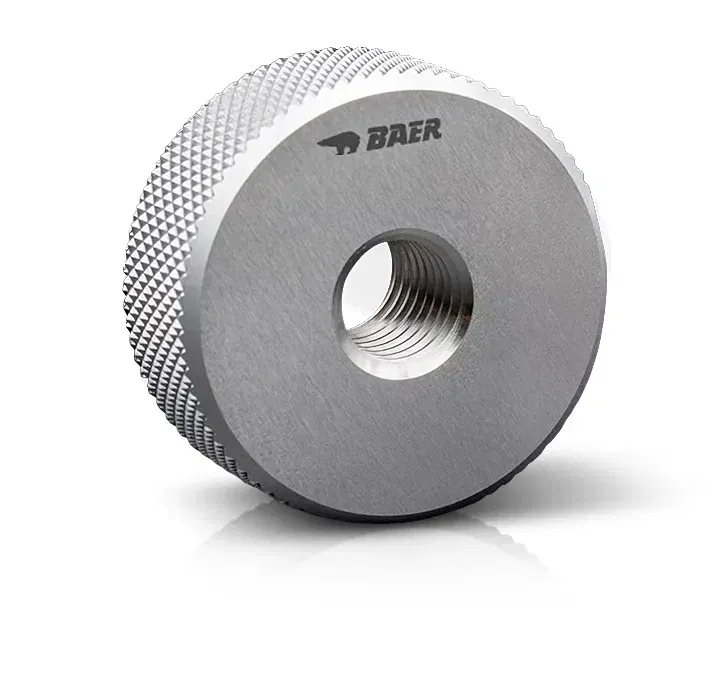

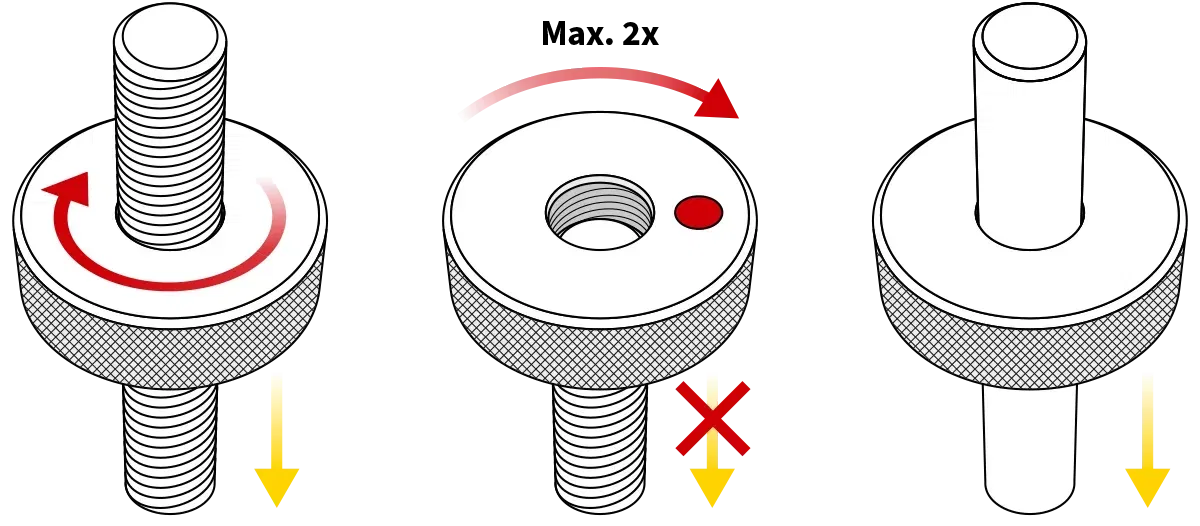

External threads are checked with thread ring gauges, which are screwed onto the thread. The thread ring gauges, in turn, can be checked for wear using a wear testing pin.

Go thread ring gauge

With a Go thread ring gauge, you can test the maximum diameter of the thread flanks, deviations in thread pitch, and profile, and also check the length of the straight flank section. The Go thread ring gauge must be screwed onto the thread by hand without significant force.

No-Go thread ring gauge

The No-Go thread ring gauge, identified by its red circular mark, tests the thread flank diameter. For thread inspection, it should not screw onto the thread more than two threads when done by hand without significant effort.

Plain gauges for external thread outer fiameter

For gauging the outer diameter of the external thread, there are plain gauges. The Go gauge ring should slide over the thread entirely, while the No-Go gauge should slide no more than two threads.

Still have questions about checking threads? Then contact our BAER customer service! And in the online shop of

screw tap manufacturer BAER, you'll also find high-quality thread gauges that allow you to check your threads - quickly and easily.