Cutting Oil for Metalworking: Optimal Lubrication for Better Results

It’s a small step in the threading process that you might have skipped before: lubricating the tool. However, products like cutting oil or drilling oil are crucial in metalworking for achieving high-quality results and long tool life. So it’s worth investing a little time and money here to save both in the long run!

But what exactly does cutting oil do when threading, and what options are available? We'll take a closer look in this blog post. We’ll also explore the important question of how environmentally friendly such a lubricant really is. Curious? Then keep reading to learn everything you need to know about lubrication.

Running Smoothly: Why Cutting Oil Is Important

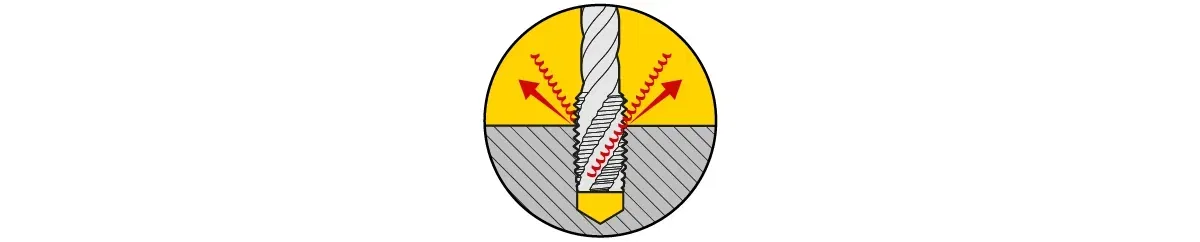

Just like in other metalworking processes, machining generates friction and, depending on conditions, considerable heat. These undesirable effects lead to increased tool wear and, ultimately, reduced surface quality. Cutting oil and similar products primarily serve two functions: cooling and lubrication. Depending on the process, one benefit may outweigh the other.

Cooling

Coolants and lubricants with a focus on cooling help reduce thermal stress on the tool and workpiece. High cutting speeds, in particular, generate high temperatures, making adequate cooling essential.

Lubrication

When it comes to threading, the lubrication performance of a coolant-lubricant is most important. Reduced friction lowers cutting forces and improves chip evacuation.

Chip Evacuation

Coolants can also directly support chip evacuation. Especially in large manufacturing systems, these products are continuously sprayed onto the tool to flush away chips.

So, not all coolants are created equal. The selected product must match the process and materials used to ensure optimal results.

High-Performance Cutting Oil or Cutting Paste: Types of Coolants and Lubricants

There is a wide range of lubricants, differing in base composition, viscosity, and performance. In industrial settings, economic factors are key: companies aim to produce quickly without sacrificing quality while maximizing tool life. If you're a tradesperson or hobbyist threading now and then, your selection is much more manageable.

DIN 51385 Classification: Water-Miscible vs. Non-Water-Miscible Coolants

Coolants are classified according to DIN 51385. The distinction is between non-water-miscible products, typically oil-based, and products that must be mixed with water before use. These are available as solutions or emulsions.

Beyond cooling and/or lubrication, coolants can be enriched with additives to expand their performance range. These may include rust inhibitors, anti-foaming agents, or viscosity modifiers to ensure usability at low temperatures. Selecting the perfect coolant in industrial production quickly becomes a task for experts.

Products for Home and Workshop Use

Outside of industrial settings, things are thankfully a bit simpler. For small-scale use, cutting oils and pastes have proven effective. Pastes are particularly suited for home use, as they can be applied directly to the tool and workpiece without additional equipment.

When choosing a product, make sure it’s designed for machining and compatible with the materials you plan to work with.

Sustainability and Environmental Protection

Due to their ingredients, some coolants pose health and environmental risks. Their use and disposal are therefore strictly regulated in industrial contexts. However, even in your home workshop, you can contribute by considering environmental factors when purchasing.

Products Free of Harmful Substances

Today, lubricants are available without problematic additives like petroleum, chlorine, and sulfur. If you look for these specifications when buying, you’ll be doing both your health and the environment a favor. Our tip: Try the high-performance cutting paste from the BAER Online Shop!

Cleaning and Reuse

The best environmental approach is to minimize waste. In industrial systems, coolants are filtered, cleaned, and reused. This creates a closed-loop system where the product is recycled over and over.

How often a coolant can be reused depends largely on economic factors. Recycling saves money, but each cycle reduces product purity, which can negatively impact lubrication performance and surface quality. Service life can range from a few weeks to several years.

Environmentally Responsible Disposal

Once a coolant can no longer be used, it must be disposed of. Companies are required to follow strict legal regulations, as lubricants are classified as hazardous waste. Disposal is handled by specialized service providers who ensure environmentally responsible treatment.

As a private user, you don’t need to worry about this. In your home workshop, you’ll typically only have small amounts left, which can be wiped away with a soft cloth. For your own safety, be sure to avoid contact with skin and eyes, and do not ingest any of the lubricant.

You’ll find cutting oils and pastes for every application in our BAER Online Shop. For more information, check the product pages or reach out to our friendly customer service team. Contact us by phone or conveniently via our customer service. We look forward to hearing from you!