Cutting external threads: How to make it work for you

Cutting external threads yourself can be particularly useful when you are working with unusual dimensions or when you need a thread directly on a workpiece, such as a pipe. In this manner, you can also re-cut dirty or damaged external threads.

Cutting external threads is not hard and can easily be done by hand or with a machine. In this blog post, we explain what equipment you need and which diameter is important for cutting external threads, helping you avoid common mistakes.

The tools you need for cutting external threads

Before you start, ensure you have the right equipment for cutting external threads. The most important tools are the thread cutting die and the die stock. We will take a closer look at these two items shortly.

Additionally, for cutting external threads you will need:

- The bolt or rod into which the external thread is to be cut

- A file for chamfering the bolt

- Cutting paste or cutting oil as a lubricant to reduce friction

The star of the show for cutting external threads: The thread cutting die

Nothing happens in cutting external threads without the thread cutting die. Let's first take a closer look at this tool.

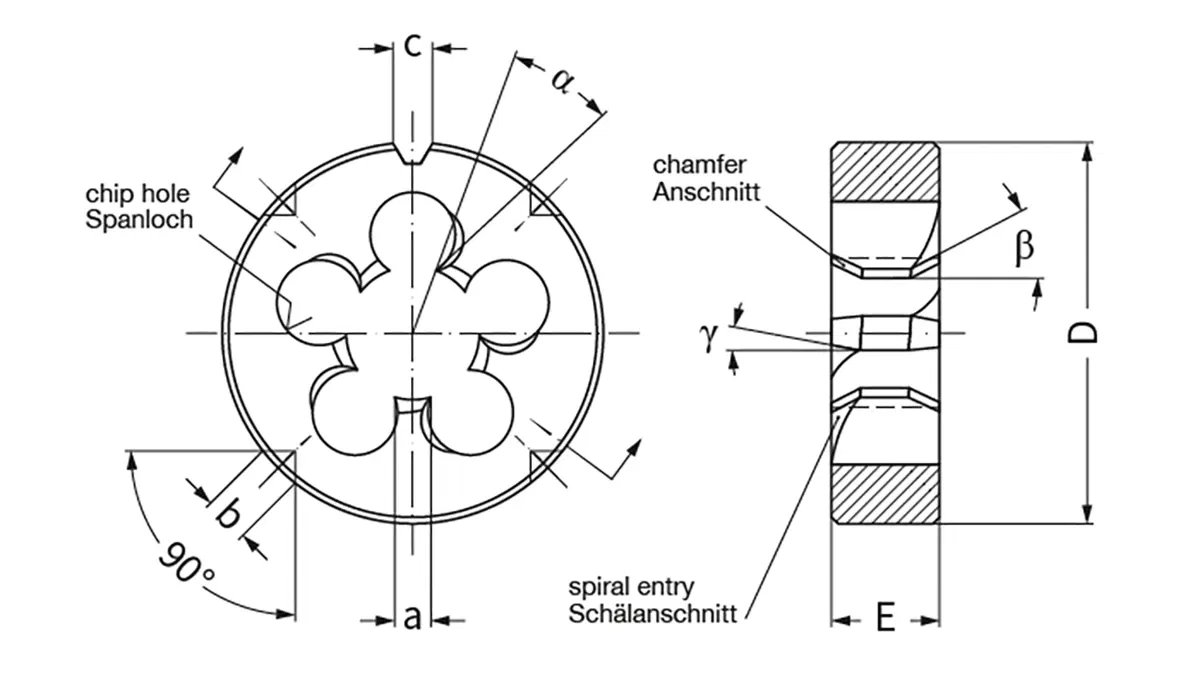

The thread cutting die is shaped like a flat cylinder. Inside this cylinder is an opening that somewhat resembles the shape of a flower bloom. To cut the external thread, you'll find toothed stiles with multiple thread turns here – the exact number depends on the design. Distributed evenly around it, like petals, three or more chip evacuation holes ensure that the resulting shavings can escape. On the outside of the thread cutting die, there is a V-groove and several holes used for fixing.

In addition to this standard design, there are some special forms for cutting external threads. Automatic thread cutting dies, for example, have two additional retaining holes. Bell thread cutting dies are noticeable due to their one-sided curved form, and the hexagon die nuts can be used with a standard wrench, which is why they are primarily used for re-cutting and repairs.

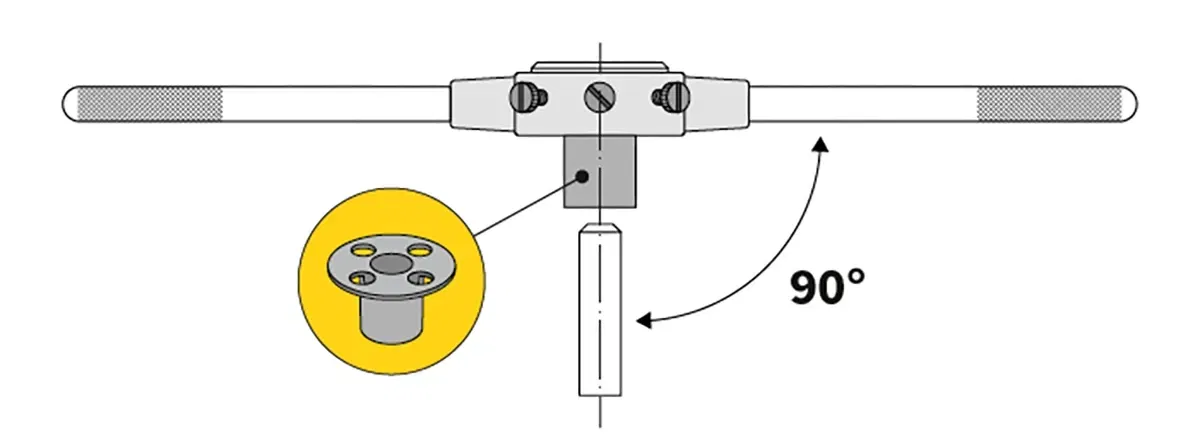

Essential accessories: Die stock and die guide

You won't get far in cutting external threads with just the thread cutting die; you also need a suitable holding tool. If you're cutting an external thread by hand, you'll use a die stock. The die stock has a body with a circular opening into which the thread cutting die can be inserted. Fixing screws, which correspond to the holes in the cutting die, securely hold the tool during the external thread cutting. Long handles ensure a good grip and optimal power transmission.

A thread cutting die can also be used for cutting external threads with a stationary drilling machine. For machine use, you don't need a die stock but a special chuck for your die. Again, you clamp the thread cutting die with fixing screws. By the way, you don't need a special machine die to cut the external thread!

While not absolutely necessary, a die guide is highly recommended. This small tool is simply placed in the die stock before cutting the external thread and helps ensure the tool is perpendicular to the bolt. Quite handy!

Cutting external threads: What should you pay attention to?

Cutting an external thread is not a complicated process. Especially if you already have some experience with threading. However, we would like to highlight a few points:

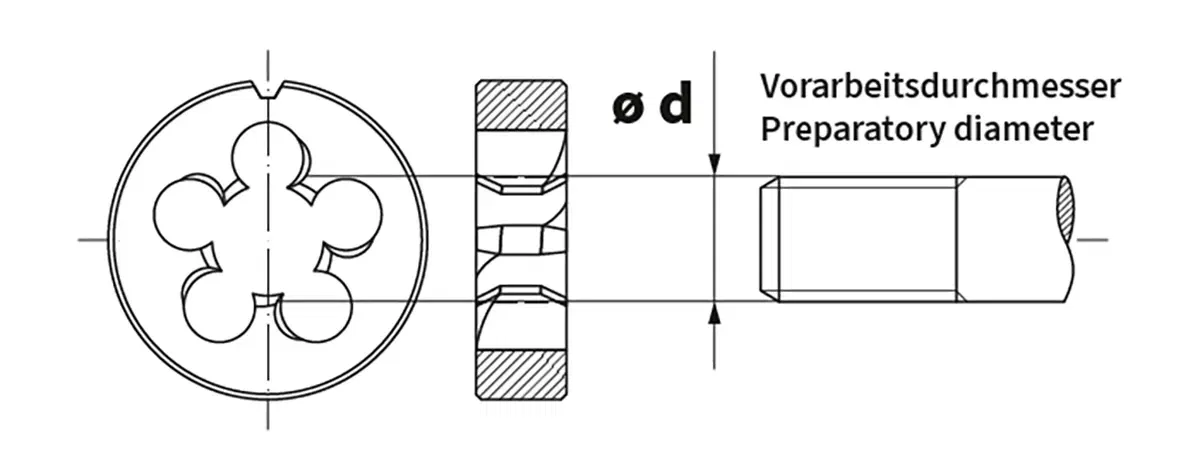

- Bolt pre-working diameter: When cutting external threads, the diameter of the bolt is a critical factor for a successful thread cutting (similar to the core hole diameter for internal threads). This must be below the nominal dimension since the thread cutting die only cuts the thread and does not reduce the bolt to the appropriate diameter. If you can't find a bolt with the correct dimensions, you can easily adjust it to the right size on a lathe. In the BAER online shop, you will find a table with the corresponding information.

- Everything in line?: Especially when cutting external threads by hand, it can be a bit tricky to always keep the die stock straight. But this is particularly important since only straight-cut external threads function as they should. It's best to use tools like a die guide and work calmly and carefully. Chamfering the bolt also helps create a straight start.

- Feed: when working with a machine, make sure to set the correct feed rate. The feed depends on the thread pitch since the thread cutting die must cut one thread per one turn.

Cutting external threads made easy with our guide

Here's how you proceed if you want to cut an external thread:

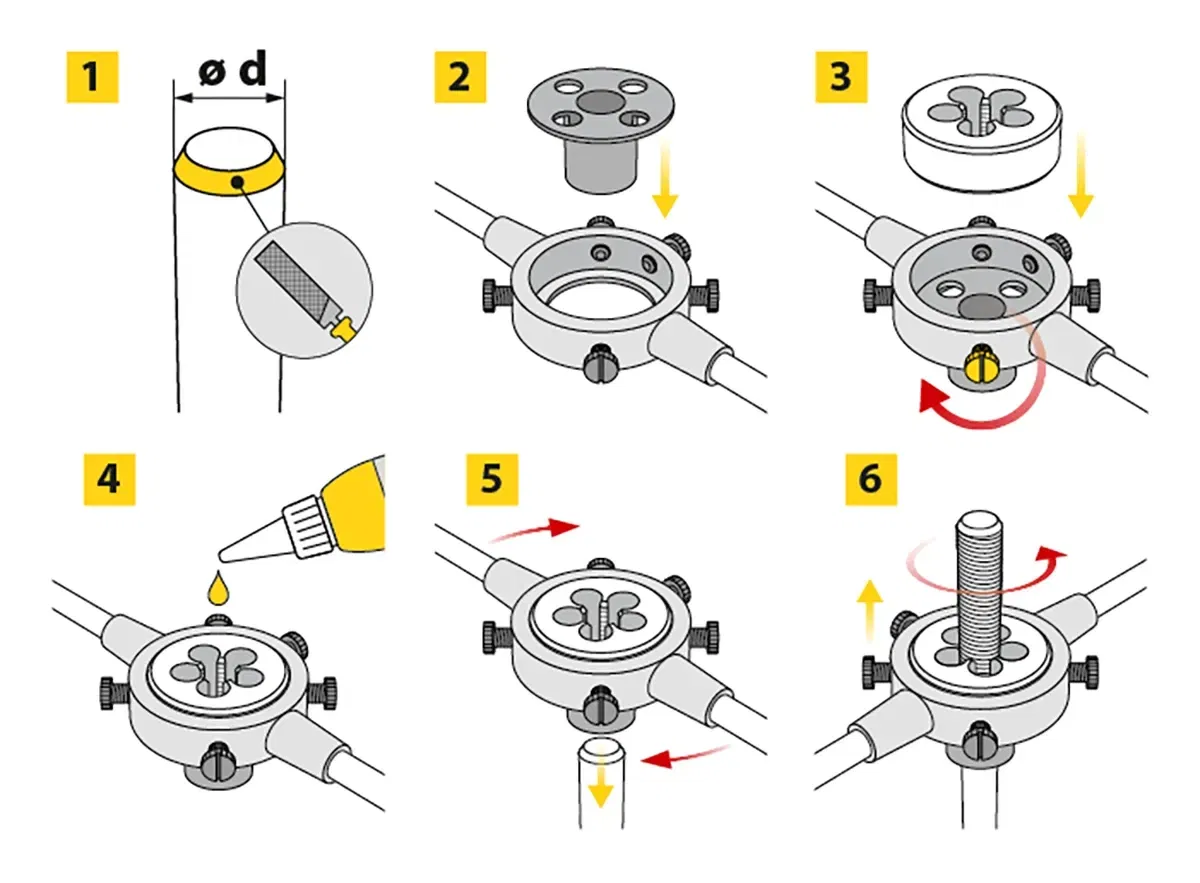

- 1. Adjust the bolt to the correct diameter and chamfer it with a file.

- 2. (Optional) Insert the die guide into the die stock.

- 3. Insert the thread cutting die into the die stock or the die chuck for the machine and tighten the fixing screws.

- 4. Moisten the thread cutting die and cutting edges with cutting paste or cutting oil.

- 5. Carefully turn the thread cutting die onto the bolt. You'll need to apply a bit more pressure for the initial cut, after which the thread vutting die is automatically guided by the already cut threads.

- 6. After cutting the desired length, turn the thread cutting die counterclockwise to remove it from the bolt.

- 7. And there you have the newly cut external thread!

What mistakes can occur when cutting external threads and how can they be avoided?

Things don't always go smoothly when cutting external threads. We'll show you some common problems and explain the potential causes.

A frequently occurring error is a rough surface. If you notice this on your thread, you should re-check the bolt pre-working diameter and ensure you're using enough lubricant. Your thread cutting die might also not be suitable for the material in use, or it might simply be dull or dirty.

If you find you're applying a great deal of force when cutting an external thread, you might have forgotten the lubricant. Use some cutting paste or cutting oil every time you cut to reduce friction.

Is the thread cutting die getting stuck and can't turn? You're probably not holding the tool perpendicular to the axis of the thread. The risk of breaking the die is particularly high here! Remember to hold the bolt at a 45° angle and use a die guide.

Everything you need for cutting external threads can be found in the

thread scree tap manufacturer

BAER's online shop! If you have any questions, our customer service is happy to help.