Cooling lubricants for screw taps: types & use

In every thread cutting manual, there's always a mention of using cooling lubricants for screw taps. This advice should never be ignored! Cutting processes, like thread cutting, create friction. This results in more heat, wear on the tool, and unsightly surfaces on the thread. If you don't use cooling lubricants for screw taps, you risk damaging both the tap and the component.

Within the realm of tap lubrication, there are numerous products with a variety of specialized features for all sorts of applications. This starts with consistency and goes all the way to the inclusion of specific additives to provide qualities such as corrosion protection or even better lubrication performance. With such a broad spectrum of products, it can be overwhelming. We'll clarify the differences and guide you on what to consider when choosing cooling lubricants for taps.

What cooling lubricants for screw taps must accomplish

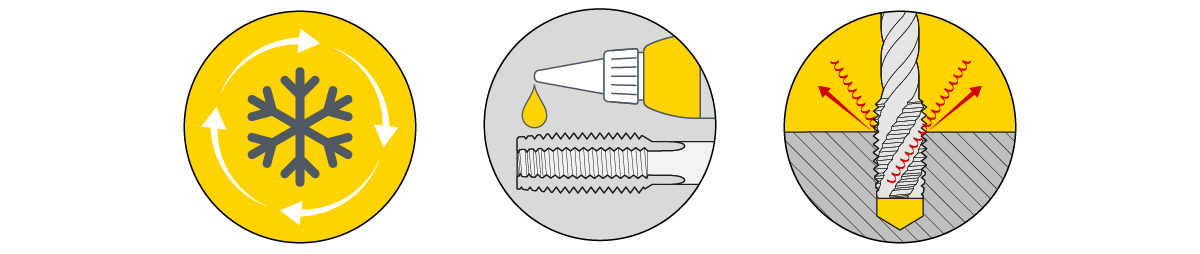

The primary functions of cooling lubricants for screw taps and dies are implied in their name. They're meant to cool and lubricate. However, these functions are not equally prioritized. Depending on the machining process, one function may outweigh the other. The necessary cooling effect is related to the cutting speed, while the lubrication effect tends to decrease with higher cutting speeds. This means there's a greater emphasis on lubrication in cooling lubricants for screw taps.

Additionally, cooling lubricants for screw taps aid in chip removal. They ensure that the removed material is transported away smoothly. In an industrial context, where coolants are continuously provided in large volumes, these lubricants effectively wash away the chips.

The roles of cooling lubricants for screw taps summarized:

- Cooling effect

- Lubricating effect

- Chip removal

Available types of cooling lubricants for screw taps

Cooling lubricants are standardized according to DIN 51385. This standard differentiates between water-miscible and non-water-miscible lubricants. Thanks to various possible additives, the properties of cooling lubricants for screw taps can be fine-tuned. This includes the addition of EP additives or high-pressure additives, which can significantly enhance the lubrication effect.

Non-water-miscible cooling lubricants for screw taps

The basis for non-water-miscible coolants is typically mineral oils enriched with other additives. These coolants form an oil film on metal that adheres well and is pressure-resistant. The properties of non-water-miscible coolants focus mainly on lubrication, and their other ingredients are chosen with this in mind. Suitable additives include corrosion inhibitors, foam suppressants, and anti-fog agents.

Water-miscible cooling lubricants for taps

Water-miscible cooling lubricants need to be mixed with water before use. Because water conducts heat well, these lubricants are especially effective in dissipating heat generated during the machining process. Water-miscible coolants contain additives like emulsifiers, antioxidants, and corrosion inhibitors. EP additives are also commonly found in these coolants.

Applications of cooling lubricants for taps

The type of cooling lubricant for screw taps used primarily depends on the material being worked on. When cutting threads into steel, a water-mixed coolant is usually employed. It should be applied precisely and evenly for maximum effectiveness. For hard-to-machine alloys like INCONEL, non-water-miscible coolants are sometimes used. These need to be fluid and are applied in large amounts to the work area.

The case of magnesium demonstrates the careful considerations required when using cooling lubricants for taps. If water-miscible coolants are used for magnesium, the machining process can produce magnesium hydroxide and hydrogen. Hydrogen can combine with the surrounding air to form explosive mixtures. This risk can be mitigated by using a coolant with a high pH level.

Another scenario requiring attention is when working with titanium or its alloys. When machining these materials, ensure that the coolant doesn't contain chlorine, as this can lead to stress-corrosion cracking.

How thread cutter lubrication looks in practice

In industrial settings, the supply of cooling lubricants for thread cutting tools and drill bits must be consistent and even. After all, even a minor interruption in the lubrication film can have significant consequences. The coolant can either be directed internally through the tool or externally sprayed from nozzles.

If you're cutting threads in your hobby workshop or garage, the process is simpler. Just manually apply your chosen cooling lubricant for srew taps to the tool and reapply as needed. This way, your threading process will run smoothly.

Which cooling lubricant for screw taps is right for you?

Selecting the appropriate lubricant is a science in itself. Various factors come into play, such as the cutting conditions, the screw tap being used, and the material being processed. Fortunately, these considerations are mainly relevant in industrial production, where there's a focus on optimizing efficiency and cost-effectiveness. Moreover, issues like wear become more critical when producing in bulk. Maybe a threading tool can handle a few cuts with a suboptimal cooling lubricant for scree taps, but how does it fare in continuous operation?

For occasional threading in your home or workshop, you'll often find universal products suitable for many applications. Just ensure that the coolant is truly intended for screw taps and buy only from trusted sources. Then not only will your project succeed flawlessly, but you also won't have to worry about hydrogen explosions, although admittedly, that's a very rare occurrence.

If you're in the market for a cooling lubricant for screw taps, consider checking out the cutting paste in the online shop of screw tap manufacturer BAER. It's suitable for a variety of materials and applications, easy to use, and free from petroleum, chlorine, and sulfur. If you wish to learn more about cooling lubricants for screw taps, our customer service team is always available for consultation!