Differences between fine thread and coarse thread

When searching for the right threading tools, you've probably come across various abbreviations marking different threading standards. In Europe, the letter M is the most common. It represents the metric ISO thread, which is standard in many places. You might have already worked with this threading standard and are familiar with it. But have you ever wondered why, besides the metric coarse thread M, there is also a metric fine thread MF? And what is the difference between fine thread and coarse thread? As a tap manufacturer, we have the answers for you!

Distinctions between Fine Thread and Coarse Thread at a Glance

Compared to coarse thread, fine thread has the following characteristics:

- Narrower thread profile

- Smaller pitch

- Larger core diameter

- Enhanced self-locking

- Precise adjustments possible

- Greater sensitivity to damage and contamination

The difference between fine thread and coarse thread: it's all about the profile

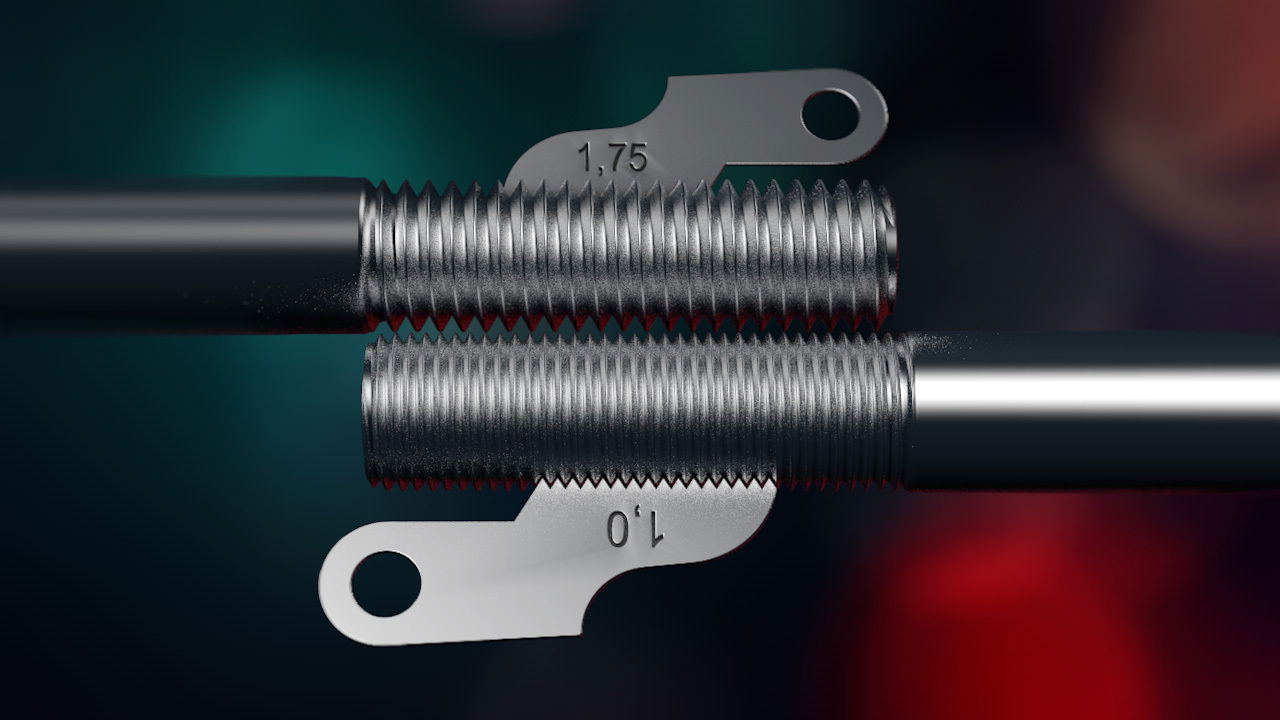

To understand the difference between fine and coarse threads, we need to talk about the thread profile. This refers to the complete set of measurements characterizing a specific type of thread. Imagine cutting a screw lengthwise. Viewing the thread, you'd see a series of thread turns, a continuous sequence of peaks and valleys. The "mountain slopes" are called flanks, and the angle between two adjacent flanks is the flank angle. The distance between the peaks of two adjacent threads is called the pitch. And right here, we find one of the primary differences between fine and coarse threads.

The thread profile of a fine thread is narrower than that of a coarse thread. Specifically, the pitch is smaller, but the external diameter and the flank angle remain the same as the coarse thread of the same size. This means the thread depth decreases, and the core diameter increases. In simpler terms, a fine thread has more threads over the same length than a coarse thread. This is a significant difference!

The Pitch Matters

The smaller pitch is the most notable distinction between fine and coarse threads. But what implications does this design have on the physical properties of the threaded connection? To understand this, think of tightening or loosening a screw as pushing or pulling a load on an inclined plane. It's essentially the same, but with a screw, the inclined plane wraps around the bolt. A smaller pitch leads to a smaller lift, a critical difference between metric coarse thread and fine thread. This is the basis for two highly desirable properties in fine threads: an enhanced self-locking mechanism and fine-tuning capability, both of which we'll explore next.

The pitch in fine threads is also noteworthy for another reason: it's always indicated in their designation. With coarse threads, a specific pitch is assigned to each nominal size. So, if you purchase screws or threading tools labeled M 10, they always have the same pitch. With fine threads, things are different since various combinations of nominal diameter and pitch are possible. Hence, you'll find designations like MF 10 X 1. This is another difference between fine and coarse threads.

Applications of Fine Threads

Knowing the differences between fine and coarse threads, we can infer the primary applications of fine threads.

The small lift allows for highly accurate adjustments. Hence, fine threads are often used for measuring and adjustment screws — anywhere precision adjustments are needed.

Due to their enhanced self-locking capability, fine threads don't easily loosen, even under vibrations and shocks. If you want a solid connection under such conditions without using a screw lock, fine threads are an excellent choice.

The shallower thread depth makes drilling a receiving thread easier. For example, a hand tap set for fine threads consists of only two drills compared to three for coarse threads because less material needs to be removed.

This smaller thread depth becomes advantageous when threading thin-walled components. In contrast to fine threads, a coarse thread might not fit due to its deeper profile.

With their tighter thread profile, a fine thread is stronger than a coarse thread of the same size. This strength becomes vital when space is limited.

Drawbacks of Fine Threads Compared to Coarse Threads

If fine threads have so many advantages, why do we still need coarse threads? As you might suspect, the differences between fine and coarse threads also bring some less-desirable traits in various applications.

The main issue is that due to their specific construction, fine threads are much more sensitive than coarse threads. They can easily seize up and jam during tightening, particularly during high-speed assembly. Their shallow profile also means they get dirty more easily and can strip more readily.

Especially in industrial production, the differences between fine and coarse threads can lead to a slower assembly since the smaller pitch angle requires a more extensive rotation angle. For load-bearing connections, unless there's a concrete reason for using fine threads, it's best to opt for coarse threads.

If you're looking for thread taps for fine threads for your next project, check out our online shop! At BAER, you'll find taps for the metric fine thread and many other international standards. If you have questions about thread types or our products, please don't hesitate to contact us. Our friendly customer service is always here to help.