Drill chuck types - everything you need to know

Many DIY enthusiasts love to talk at length about the power of their driling machines or the special drill bits they've just acquired. In the process, other parts might be overlooked. Yet tool holders, like the drill chuck, deserve your full attention! After all, the success of your project largely depends on how well the machine and the tool, with all its various parts, work together. A good drill chuck plays a significant role in this, even if it often stays in the background. In this blog post, we'd like to highlight it and present it as what it truly is: the element that holds everything together. Let's shine a spotlight on the drill chuck!

What exactly is a drill chuck?

The drill chuck is a tool holder and thus serves as the link between the tool and the machine. In this capacity, it not only bears a lot of responsibility but also has to meet a few essential requirements. A good drill chuck should securely grip the shank of the tool, hold it firmly, and transfer the generated forces to the machine. At the same time, a good drill chuck should also be practical in use.

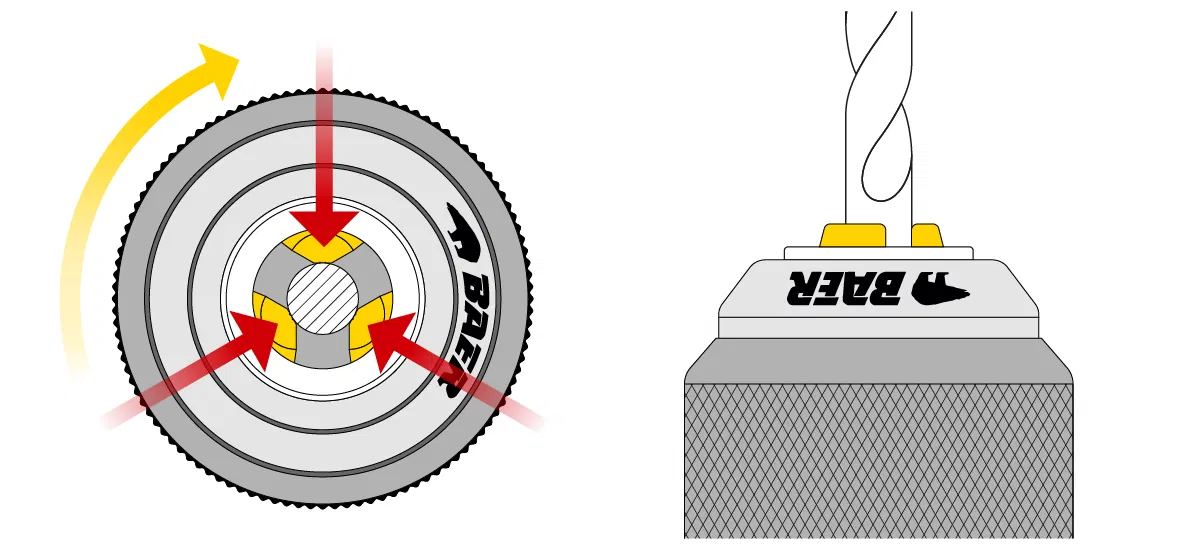

There are many types of tool holders, such as shrink-fit chucks or collet chucks. However, by far the most commonly used is the 3-jaw drill chuck, which you've probably used yourself. The number of clamping jaws is crucial here, as it ensures good centering of the drills. The uniform force application from three sides in a good drill chuck ensures that the tool is perfectly centered.

In the past, you had to tighten the drill chuck using a ring gear. This could only be done with a tightening key, which you always had to have on hand. Moreover, such a gear drill chuck required two hands for operation. That's why, among the types of drill chucks, the keyless drill chucks have become widely adopted. These make tool changes very quick and convenient, and depending on the design, can even be opened and closed with one hand.

What types of drill chucks are there?

Before you go out and search for a good drill chuck, you need to determine what purpose it's meant for. We can distinguish between drill chucks for handheld and stationary machines.

Hand-held machines such as drilling machines or cordless screwdrivers typically feature a threaded connection and a set screw, which prevents the drill chuck from being rotated off the machine in reverse. These drill chucks for handheld machines must provide a secure grip, but they should also be lightweight, allowing you to comfortably hold the machine. They should also be user-friendly, allowing for quick tool changes.

For stationary machines, commonly used in crafts and industry, drill chucks need to be more precise and robust but can be larger and heavier. These chucks are typically attached using a tapered arbor, providing better power transmission and higher accuracy.

As a DIY enthusiast, you probably use handheld machines more frequently. However, investing in a stationary drilling machine might be worthwhile if you often need to make very precise holes. In both cases, you can optimize your results by choosing a good drill chuck.

Recognize a high-quality drill chuck by these 5 characteristics

Not only for drill bits and the drilling machine itself but also for the drill chuck, it pays to prioritize quality. As the link between the tool and the machine, it's not only exposed to intense stress, but it also has to meet high demands. No matter how powerful your machine is - if the power transfer through the drill chuck fails, a lot can be lost. Similarly, even the most precise drill bit can produce incorrect diameters if you skimp on a good drill chuck. To prevent this, we've compiled 5 characteristics to look for when purchasing a high-quality drill chuck.

Premium Material

A drill chuck's strength and stability are directly proportional to the material it's made from. Especially the clamping jaws, due to frequent opening and closing, are exposed to constant wear and tear. Inferior materials quickly show wear. A good drill chuck is made of high-quality material and does not exhibit these problems!

High Precision

A high precision is the most crucial criterion for a good drill chuck. In simple terms, the tool should wobble as little as possible. This not only leads to better drilling results but also ensures that the tools themselves last longer! However, the accuracy of rotation is influenced not only by a good drill chuck but also by the machine itself. For stationary machines, it's best to use branded devices with tapered mountings. For handheld devices, plug connections and adapters can reduce accuracy.

Strong Clamping Force

The drill bit should sit securely in the drill chuck, and that's ensured by a strong clamping force. Good drill chucks have a re-tightening effect, automatically increasing the clamping force when needed. For very tough jobs, a quick-release chuck might not be sufficient, so you'll need one that can be tightened with a key for an even firmer grip.

Long Tool Lifetime

A good drill chuck is robust and will serve you well for a long time. Don't rely solely on advertising promises. Instead, look at the experiences other users have had with the drill chuck.

High-quality Craftsmanship

It's what's on the inside that counts! A drill chuck contains sophisticated mechanics, where everything needs to be perfectly coordinated. Only when all clamping jaws apply uniform pressure can the required clamping pressure be achieved, enabling even small drill bits to be precisely centered. So, when in doubt, invest a few extra dollars in a top-quality drill chuck to save time and avoid frustrations in the long run!

If you're looking for a good drill chuck, check out BAER's online store . They offer an array of drill chuck types. With their vast experience in drill chucks, they know exactly what's essential. They'll be happy to advise you based on your specific needs!