For Everyone Who Values Flexibility: Our TriTap Taps and Twist Drills

Let’s be honest: How often have you ignored the advice not to use taps in handheld machines? Sometimes it’s simply more practical, or no other option is available. Maybe you were too lazy to clamp the workpiece in a large bench drill. Don’t worry—we’re not here to lecture you. Quite the opposite. We believe that tools should adapt to practical workflows, not the other way around. That’s why we developed TriTap.

Our TriTap taps are designed to fill a gap we frequently encounter in conversations with customers or peers. This new product line of universally usable taps and matching twist drills makes thread cutting with handheld machines easier than ever. Thoughtful design focused on flexibility and user-friendliness allows you to quickly and cleanly cut perfect threads in a wide range of materials. Want to know how it works? Keep reading.

What’s New About the TriTap Taps?

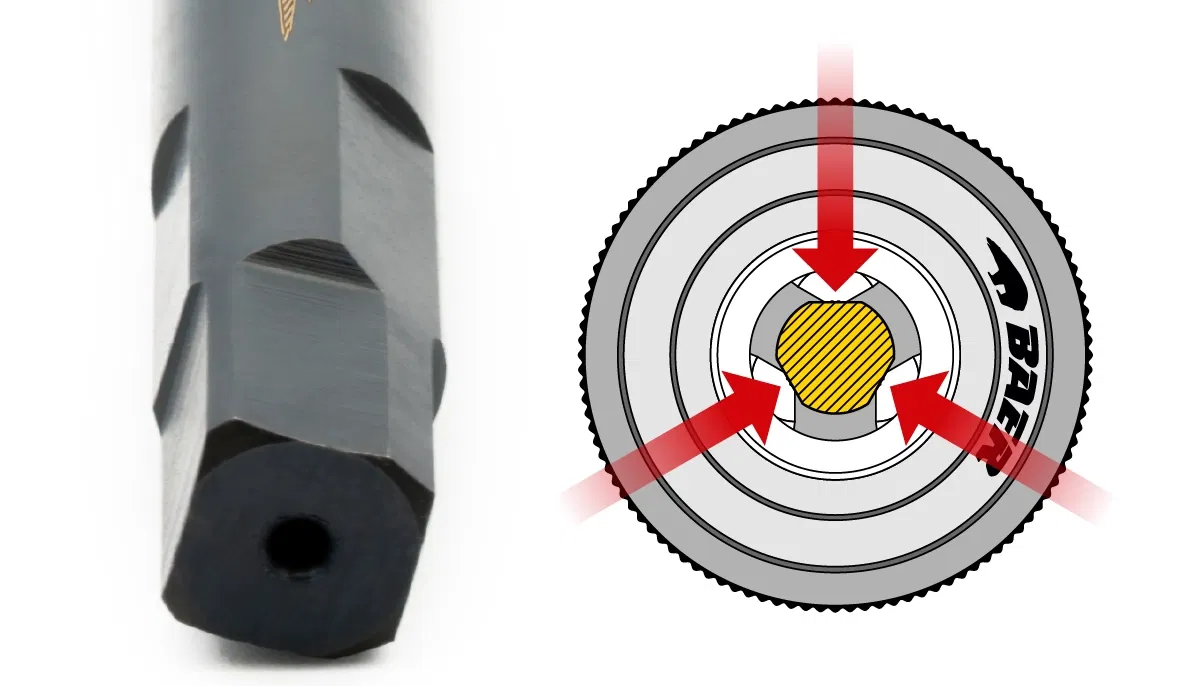

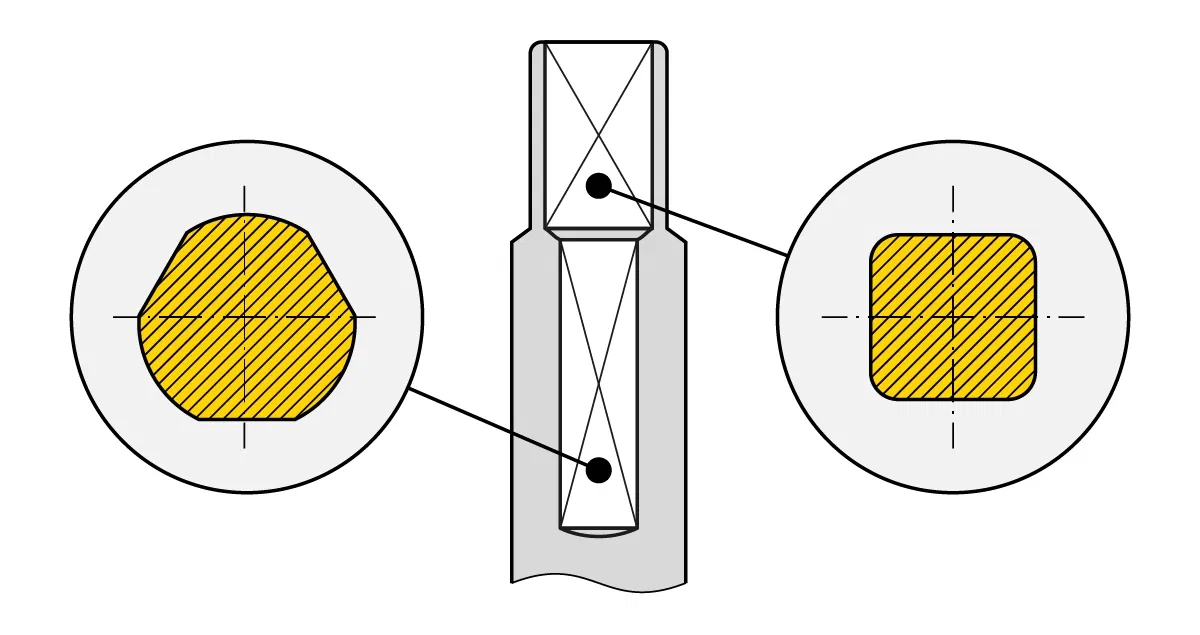

Take a look at the shank, and you’ll immediately see what makes our new TriTap taps special. It’s designed with three flat faces—ideal for a three-jaw chuck to securely grip the tap. Even when working with hard materials or demanding threading tasks, the tool won’t slip.

But that’s not all. In addition to the three-flat shank, you’ll still find the familiar square section. This clever combination of shank shapes ensures maximum flexibility. You’re free to choose your preferred machine and switch easily depending on the job at hand.

Material and Processing – Quality You Can Count On

At BAER, we always prioritize impeccable quality. Our latest innovation is no exception. The TriTap taps and twist drills are made of cobalt-alloyed high-performance HSSE (High-Speed Steel with Cobalt). That already ensures significant hardness and long tool life. Additionally, TriTap tools are vapor-coated. This surface treatment reduces friction and allows cutting oil to adhere better to the tool. That way, you can produce high-quality threads even in difficult-to-machine materials. As a bonus, vapor coating also gives the tools an especially appealing finish!

The All-Rounder – Why TriTap Is So Versatile

Our goal with TriTap was to create a tap that’s extremely flexible and suitable for a wide variety of threading applications. When you need to stay mobile—on the construction site, client job, or in a small workspace—you can’t always carry a full set of taps.

The raw material and geometry of the TriTap taps and twist drills were designed to handle most common use cases with ease—even stainless steel doesn’t pose a problem. With a set of TriTap in your toolbox, you’re prepared for nearly any scenario and can enjoy unprecedented freedom of choice in selecting your power tool.

Thread Cutting with a Handheld Machine – How to Master It

TriTap taps make freehand thread cutting significantly easier—but they don’t make it effortless. The innovative shank design provides a secure grip in handheld machine chucks, but it can’t eliminate all the challenges of this method.

To help you tackle the difficulties of thread cutting with a drill, we’ve compiled some helpful tips:

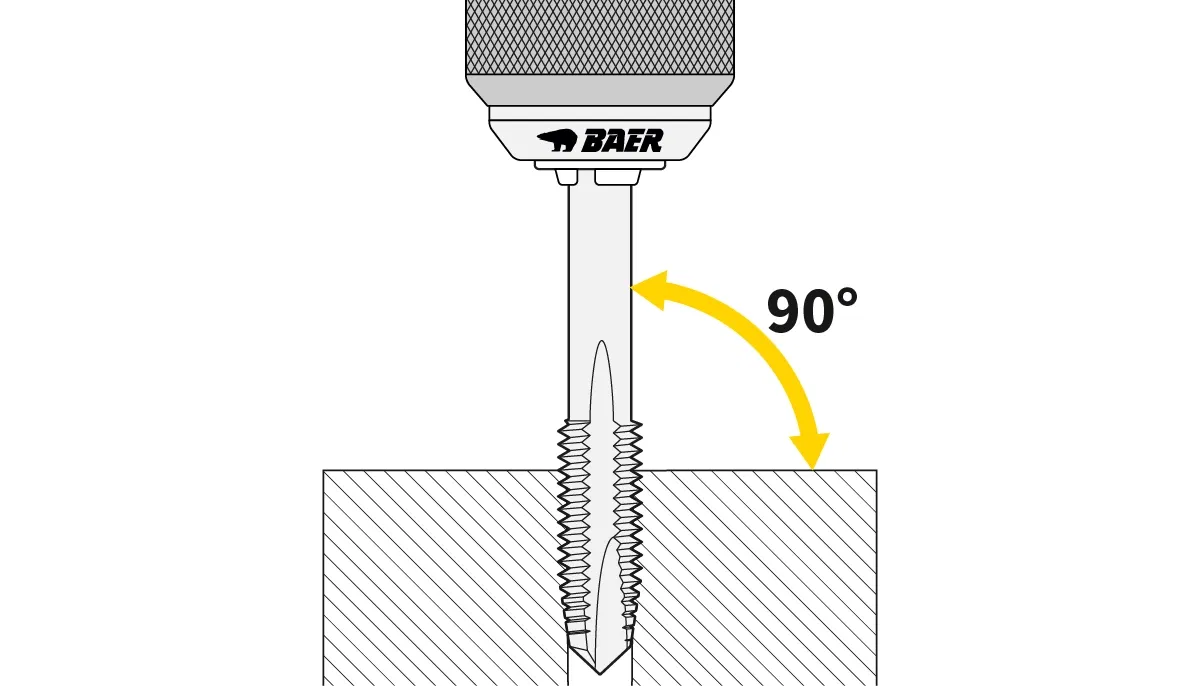

Keep the Tool Straight

The biggest source of error when avoiding a stationary drill is the angle at which the tool enters the core hole. Even slight deviations can cause you to misthread or break the tap. To prevent this, always ensure the drill is perfectly perpendicular to the workpiece surface.

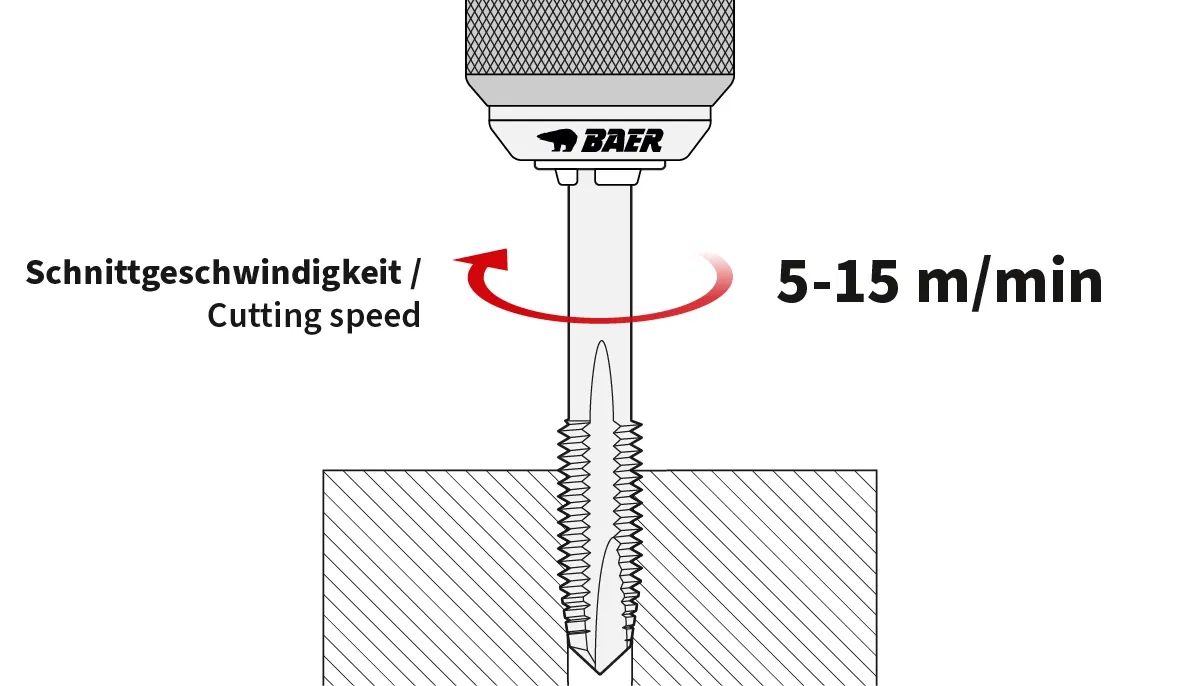

Use Low Speed Settings

The pitch of the thread corresponds to the distance the tool advances per revolution—you’ve probably heard that before. In stationary or CNC machines, feed is controlled automatically. With a handheld tool, your arm movement controls the feed. To still achieve good results, use as low a speed as possible.

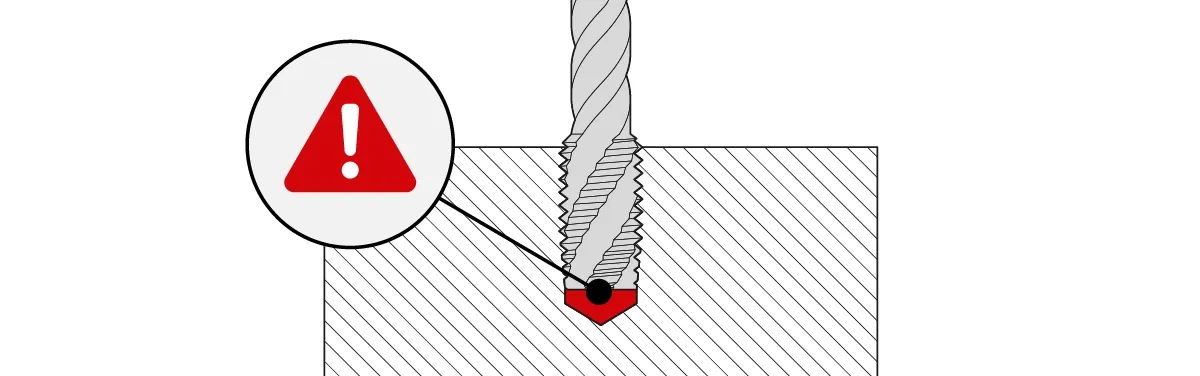

Be Gentle with Blind Holes

Blind holes can be problematic—especially with handheld machines. You should know your hole depth clearly to avoid bottoming out the tap. In stationary drills, you can set the depth and rely on the machine. With a handheld drill, you must stop and reverse early to avoid tool breakage.

Our Range – TriTap in the BAER Online Shop

Our TriTap taps and twist drills are designed for everyday use, and that’s reflected in the range. Available sizes include common metric coarse threads M3, M4, M5, M6, M8, M10, and M12, each offered for through holes (Form B) or blind holes (Form C). You can purchase the taps individually or in the elegant TriTap case, which also includes matching twist drills. The case is also offered in both blind and through-hole variants.

Your turn! Check out our new TriTap line in the BAER Online Shop and see for yourself. If you have any questions, our customer service is ready to assist you by phone or via our contact form.