For optimal tool life: How to make your taps last longer

It is one of the harsh truths of everyday craftsmanship: tool wear cannot be stopped. No matter how carefully you work and how much attention you pay, every use brings your tool one step closer to the point where it becomes unusable and needs to be replaced. This is especially true for machining. Does that mean we just have to accept it? Not quite.

The service life of taps is influenced by various factors, many of which you can control yourself. While you won’t be able to grant your tools eternal life, you can certainly extend the operating time before your tool gives out—provided you pay attention to a few important factors. In this blog post, you will learn which factors matter and how to get the most out of your taps.

HSS-TiN and more: It all starts with choosing the right taps

The most important decision is made before the work even begins. When purchasing or ordering your tools, there are many things you can do right, which will positively impact their lifespan later. Two key aspects are particularly important here:

First, the quality of your machine taps is crucial—not only for the success of your projects but also for their longevity. So, don’t be guided solely by the lowest price! With overly cheap products, you usually end up paying more in the long run because you need to replace them more frequently. Instead, check whether high-quality materials have been used and buy only from reputable manufacturers.

Additionally, the tool you use must be suited for the task it is meant to perform. Are you working with a blind hole or a through hole? Is the material suitable for the required cutting speed? What shape do the flutes and the shank have? Not all taps are the same, and choosing the right tool is one of the most important steps in the process. If the cutting edges are not designed for the material they need to process, they will wear out much faster. And selecting the wrong flute type can, in the worst case, lead to a complete tool breakage.

Careful handling: Avoid these application errors

Have you found the right tap for machine or manual use? Great! Now you can start cutting your thread. But be careful—there are still several things you can do to extend the tool life.

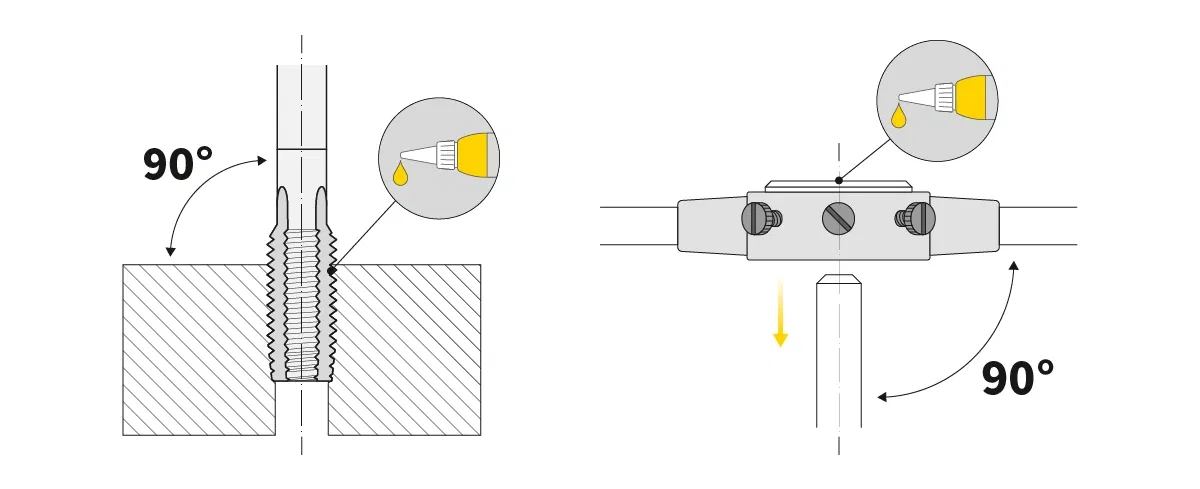

The use of cutting fluid in sufficient quantity not only facilitates the cutting process and ensures the best results, but also protects the cutting edges of your tap. Additionally, proper lubrication is the best way to prevent tap breakage. So, don’t forget to apply cutting oil or cutting paste to your tool before starting work.

Lack of lubrication is not the only risk factor for tool breakage—and this must be avoided at all costs. Once breakage occurs, your tap is beyond saving, and its remaining lifespan is instantly reduced to zero. To prevent this, ensure smooth chip evacuation to avoid clogging. The core hole must also be the correct size and drilled perfectly straight. Especially when tapping by hand, it is crucial to keep the tool perfectly aligned. While these measures may not completely eliminate the risk of tool breakage, they can certainly help prevent it effectively!

Transport and storage: How to protect the cutting edges

However, your tap is not only subject to wear during active use. Mistakes during shipping, storage, or even at home in your toolbox can significantly shorten its lifespan. When choosing a suitable supplier, always ensure that secure packaging is provided.

For storage in the garage or workshop, it is recommended to thoroughly clean your taps after use and ensure they are completely dry before storing them for a long period. The best storage solutions are those that prevent taps from touching each other or other tools.

Ideally, you should use sealed boxes where each tap has its designated place and is protected from dirt and dust. This way, you can be sure that the tap will be in the same condition when you use it again. Want more tips on how to store your threading tools properly? We've dedicated an entire blog post to this topic.

Tap regrinding: Maximize the lifespan of your tools

Even if you follow all our tips precisely, wear cannot be completely avoided. Sooner or later, the day will come when you notice that the cutting edges of your tool are beginning to dull. But all is not lost yet!

Taps can be reground. However, you should never attempt this yourself, as regrinding taps requires precision. It’s best to leave this task to professionals who can guarantee that your tools will function flawlessly afterward and produce the desired threads. If you want to learn more about how tap regrinding works and whether it is worthwhile for you, check out our blog.

BAER is your strong partner when it comes to precision threading tools with optimal tool life. We offer not only high-quality taps made from durable materials but also cutting fluids and other accessories you need for optimal use. Our regrinding service is here for you when wear has already occurred. You can also get more tips and answers to any questions from our competent customer service team.