Here you need robust threads: Automotive and Vehicle Manufacturing

Threads are indispensable in almost all industries. Screws and nuts are not only needed to connect components but also serve many other purposes. They are found everywhere and are usually of particular importance when it comes to safety and functionality.

This applies especially to the automotive industry. In a world without threads, every vehicle would simply be a useless pile of metal. And precisely because of this significance, basic knowledge about threads and thread cutting is not only important for mechatronics technicians but also for every hobby mechanic. After all, you want to be sure that a threaded connection doesn't unexpectedly come loose while driving!

But what special characteristics define automotive threads, which types of threads are unique to this field, and what do you need to know to properly maintain and care for the threads on your vehicle? We have compiled all the important information about automotive threads in a clear blog post.

What must vehicle threads be able to do?

A vehicle is, in every respect, a special application for a thread. This begins with the fact that it is not stationary. This means that the conditions a thread will be exposed to over its lifetime can change. Sometimes drastically, for example, if you use your vehicle to escape a rainy German autumn and enjoy yourself on the Côte d’Azur. However, temperature fluctuations and environmental influences such as changes in humidity must not cause a thread to loosen uncontrollably.

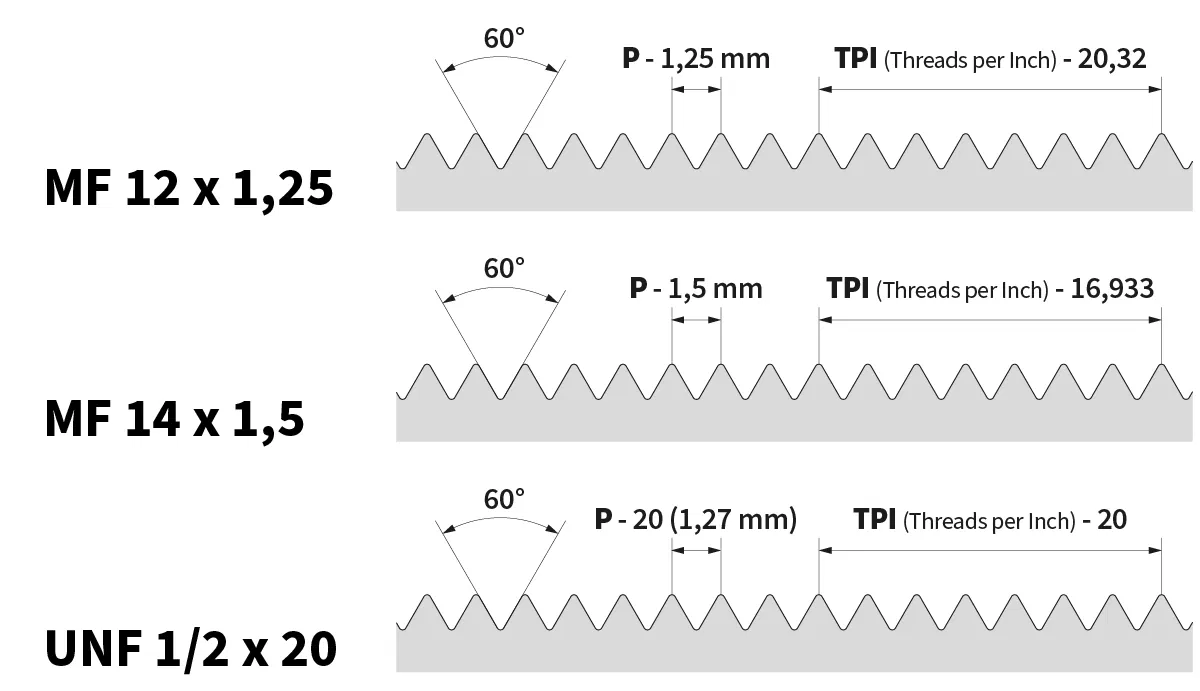

Moreover, the movement of the vehicle introduces another stress factor for the thread. In daily use, it is regularly exposed to constant vibrations or even sudden shocks. The thread must be able to withstand these without a screw coming loose on its own. For this reason, vehicle threads are often fine threads, which provide good self-locking capability.

To reliably cope with these special conditions, as a vehicle owner, you sometimes need to give your threads a helping hand. Either by taking action yourself or by entrusting your trusted workshop with the task. Besides the regular inspection and maintenance of particularly safety-relevant screw connections, you should also keep an eye on developing rust or dirt and counteract them in time.

Special threads in the automotive sector

Sure, most automotive threads can be found on fastening screws, which are also used in other fields. But there are a few types of threads that are very specifically designed for this application. We will take a closer look at three of them.

Threads on the wheels

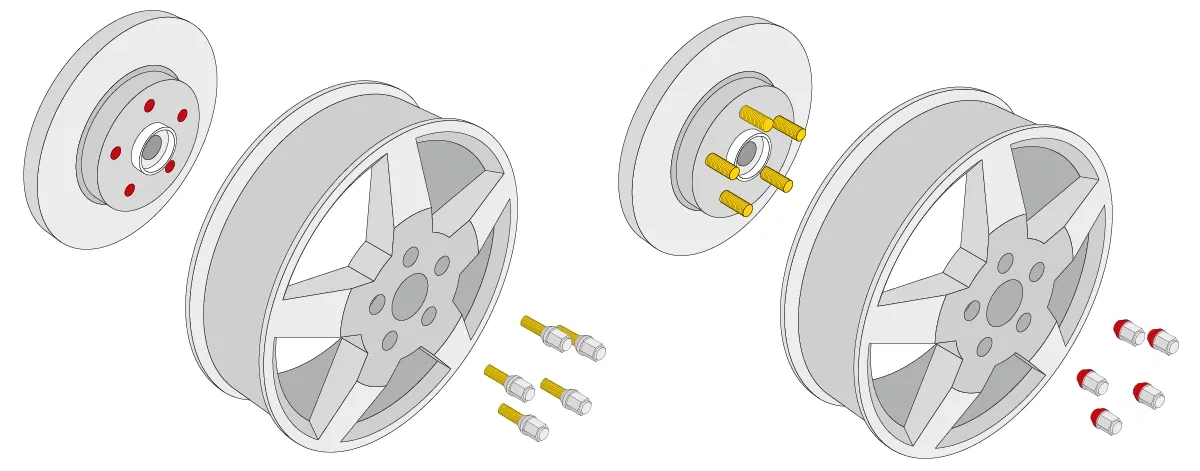

The threads on your vehicle’s wheels are likely the ones you have encountered most often—at least if you change your own wheels. Two different models are commonly used to connect the wheel and wheel hub: wheel bolts and wheel nuts.

In the wheel area, vibrations during driving are particularly strong, which is why fine threads are commonly used here. Unfortunately, these are also more sensitive to dirt and mechanical damage, and so it is not uncommon that a bolt cannot be loosened during a wheel change. How to solve this problem is explained in our blog.

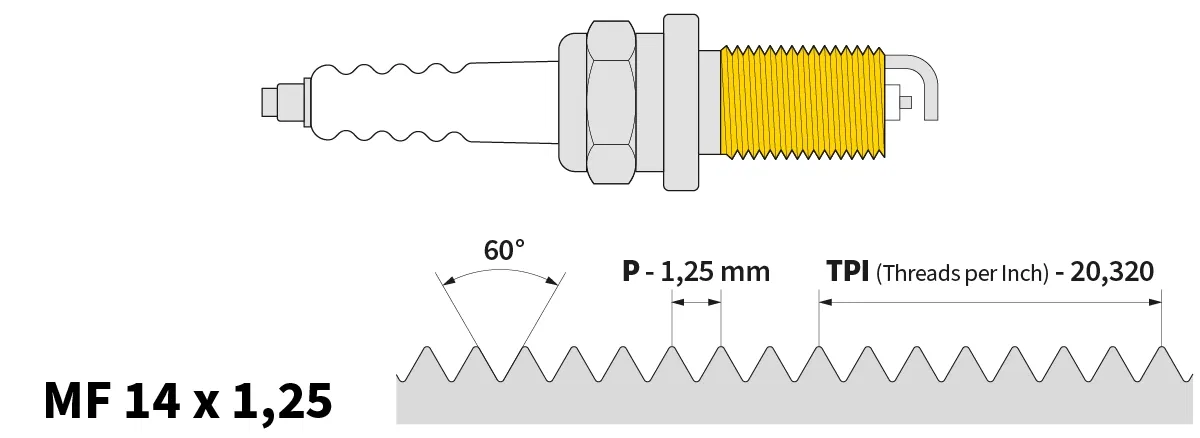

Spark plug threads

Just as important as the wheels, though much smaller, are the spark plugs. Without them, the car won’t start at all. The spark plug thread ensures that the spark plugs sit firmly in the cylinder head. In cars, this is usually a metric fine thread M 14 × 1.25.

Spark plugs need to be replaced occasionally. During this process, the delicate fine thread in the cylinder head, which is primarily made of soft aluminum, can wear out over time or be damaged due to careless handling. In such cases, a set for thread repair can be very useful—and save you enormous costs!

Oil pan threads

There are many tiny components that ensure your vehicle delivers its full performance. One of them is the oil drain plug. It sits at the bottom of the oil pan and allows you to drain the old oil during an oil change. A reliable threaded connection is particularly important here to ensure that the oil only flows out when you want it to. So, it’s worth checking this thread from time to time and cleaning or repairing it if necessary.

Repairing automotive threads

As we have seen, it doesn’t take much to damage an automotive thread. The constant load, changing environmental conditions, and not least dirt, dust, and slush all contribute to threads quickly becoming dirty, rusting, or wearing out. In case of doubt, such damage should always be repaired by a professional to ensure your safety while driving.

However, not every damaged thread requires a trip to the workshop. With the right tools, you can often fix minor issues yourself. Dirty threads on wheel bolts or nuts can usually be recut and restored using a die or a thread tap of the correct size. A thread repair kit is also useful for restoring spark plug threads or oil pan threads without having to replace an entire component.

Everything you need for the maintenance and repair of the threads on your vehicle can be found in the BAER online shop at a fair price. Discover our wide selection and fast delivery times—almost all items are always in stock and ready for immediate shipment. If you have any questions, requests, or suggestions, our friendly customer service is always available for you.