Historical Threads and Why They're Still Needed Today

Threads have a storied history—the Archimedean screw from antiquity is considered the first example. During and after the Industrial Revolution, threads—especially in the form of screws and nuts—experienced a golden age that continues to this day. But while we now live in a world of standardized thread norms and usually get by quite well with the metric thread according to DIN 13, the 19th and early 20th centuries looked very different. Join us on a little journey through time and explore the vast world of historical thread types with us.

Why Is It Worth Looking Back?

Did you just groan and wonder why you should learn even more thread types when the variety of modern versions is already overwhelming? The early developments often have effects that reach into our present. When repairing or restoring old devices, you may stumble across a thread that seems puzzling at first. If you can identify it correctly, processing it becomes much easier. And your understanding of current practices deepens when you know how it all began.

You can find thread tables for historical thread types in our overview in the service area.

An Overview of the Most Well-Known Historical Thread Types

Let’s begin our journey into a time when international thread standards were still a distant dream. Hold on tight—we’ll encounter odd angles and adventurous names!

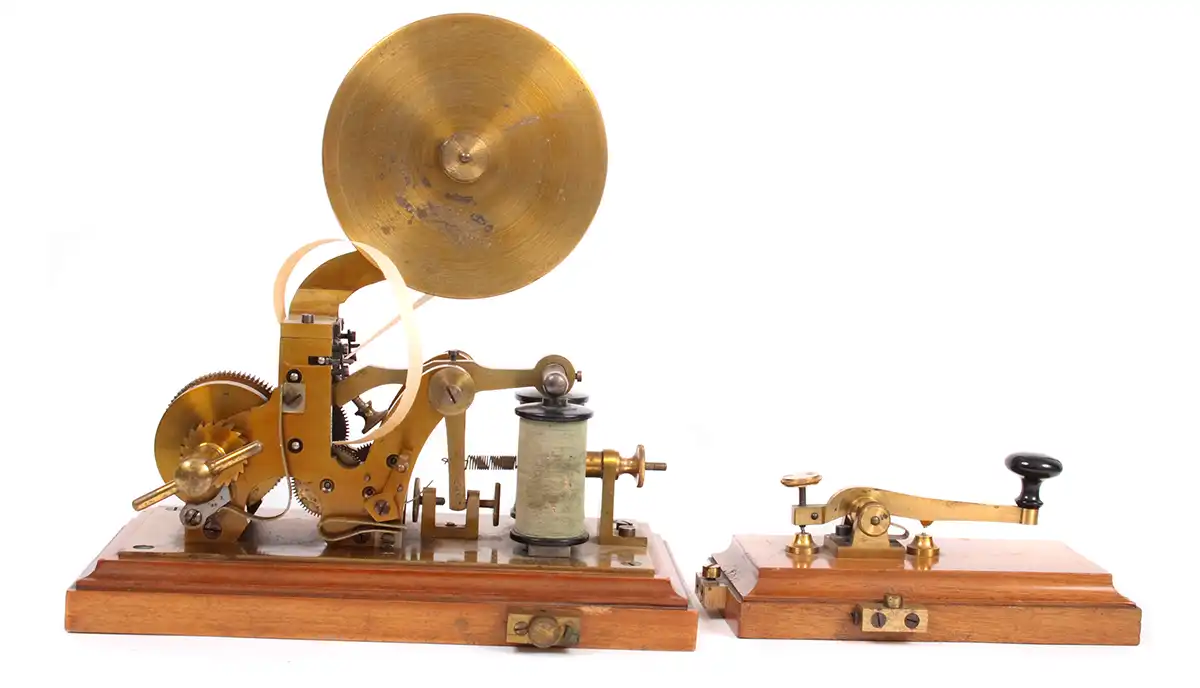

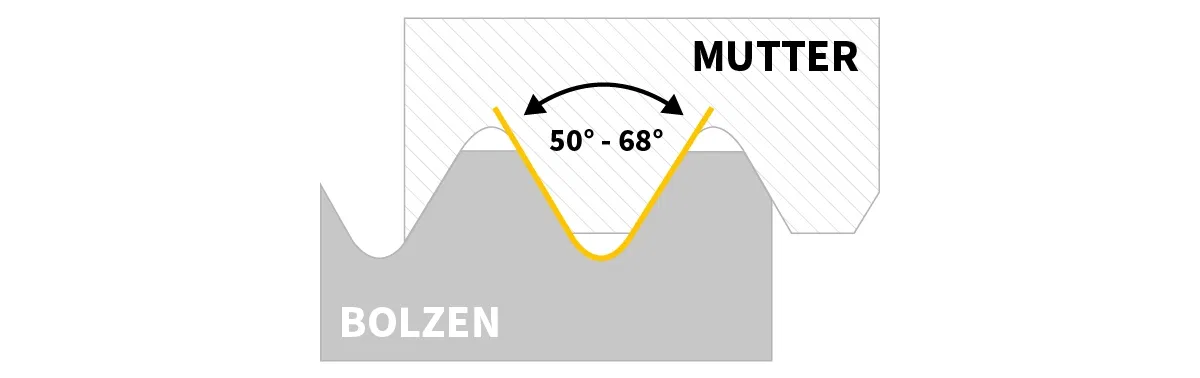

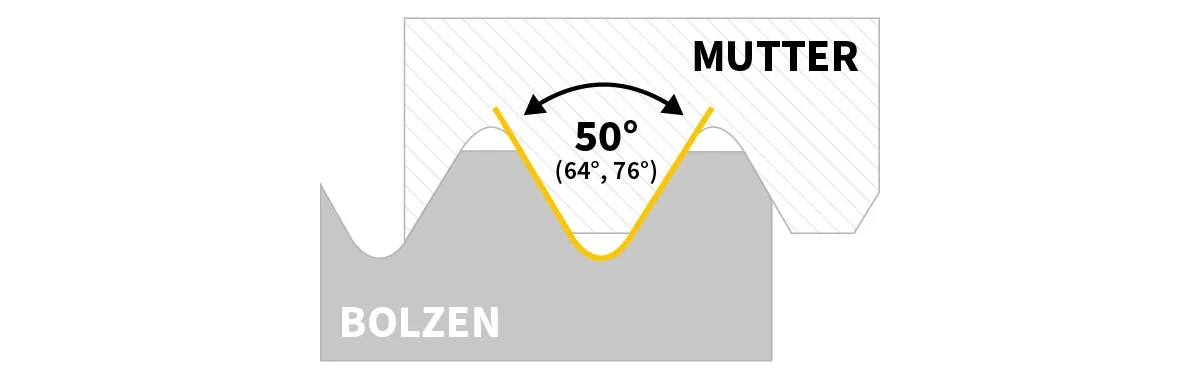

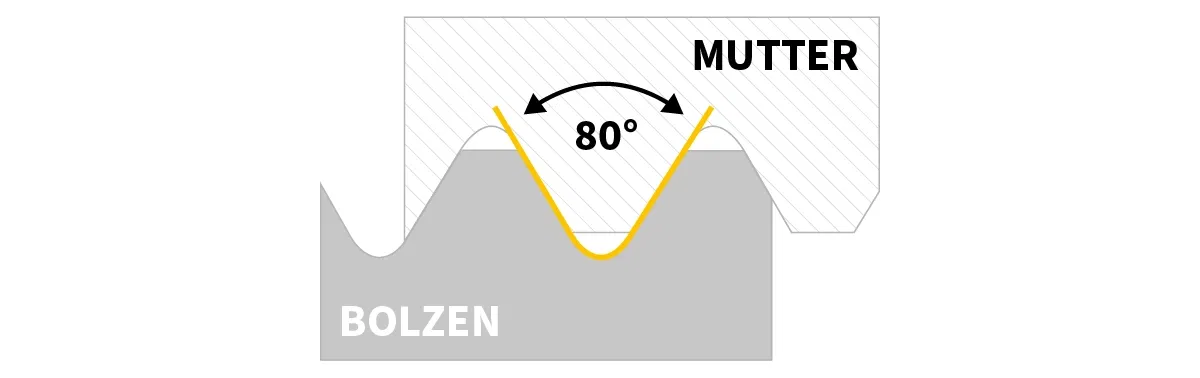

Siemens & Halske Thread

And here’s our first connection to the present—you’ll surely recognize the name Siemens. The Siemens & Halske thread originated around the turn of the century and was used for telegraphs and telephones. It is a metric thread with a flank angle ranging from 50° to 68° depending on the thread size. It is also known as telegraph thread, post thread, mechanic standard thread, or S&H thread.

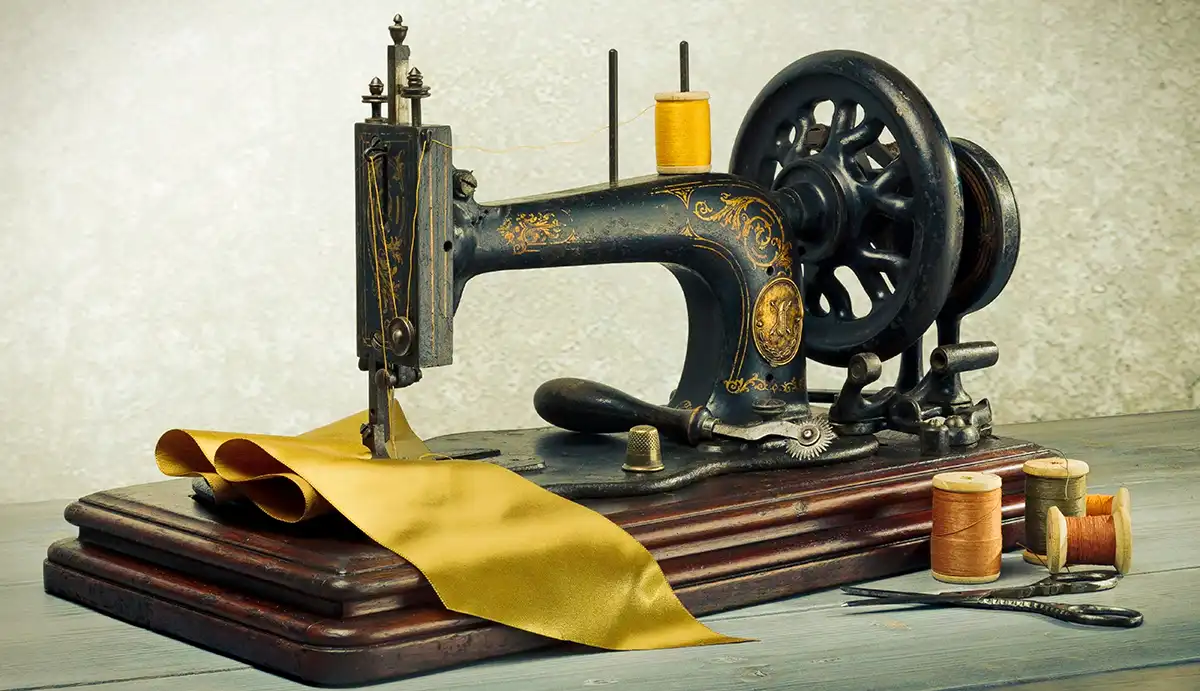

Sewing Machine Thread

The sewing machine thread was standardized according to Sewing Standard 100 and used in the manufacturing of sewing machines. It is an inch-based thread, usually denoted with the abbreviations Ng or NN.

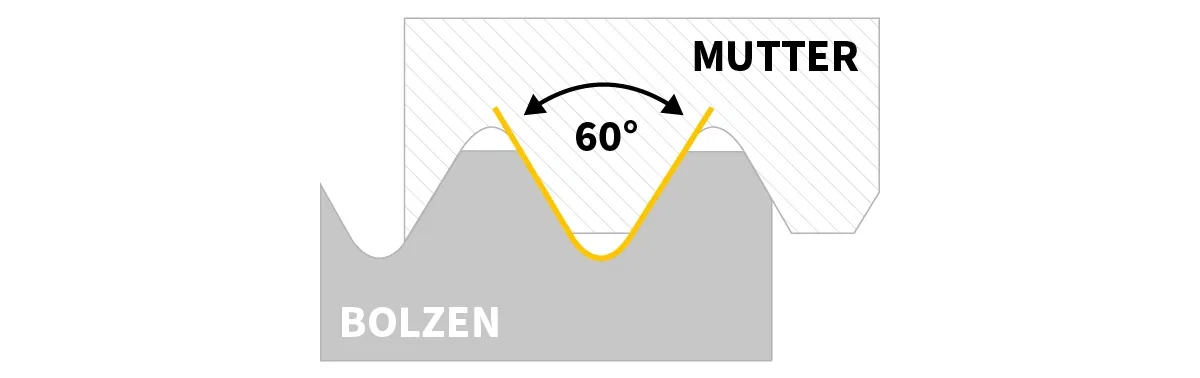

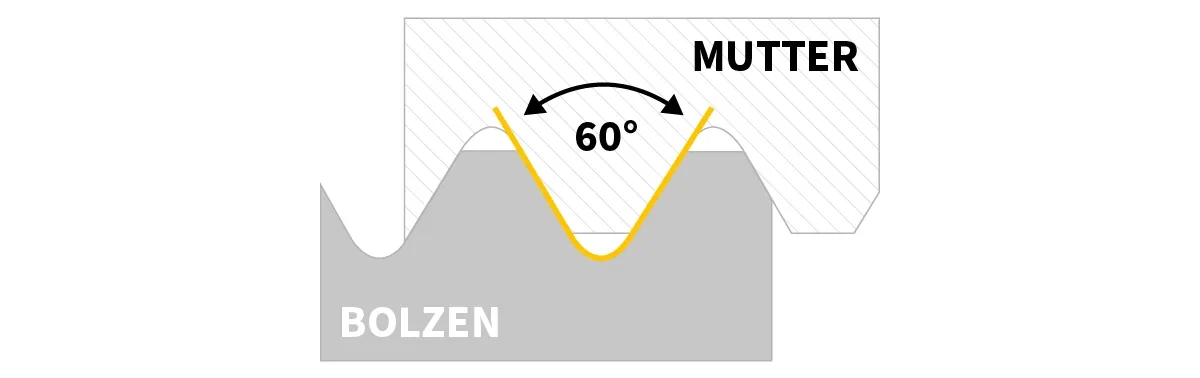

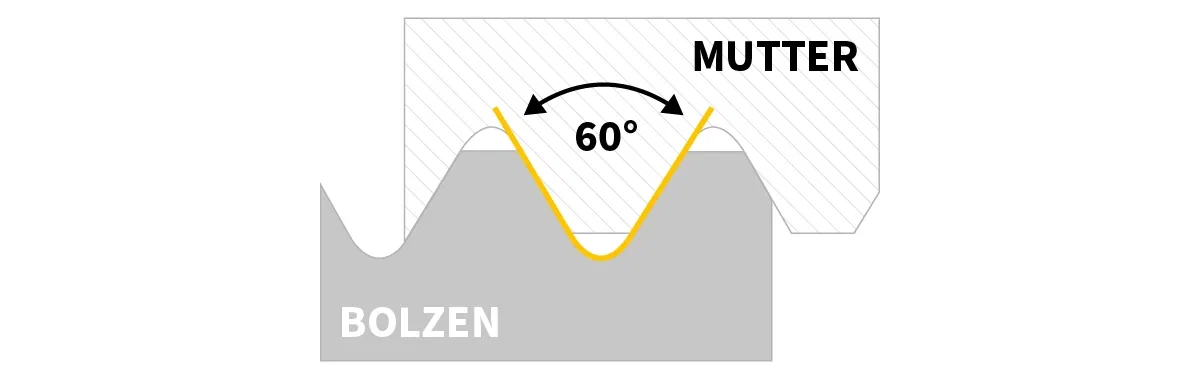

C.E.I. Thread

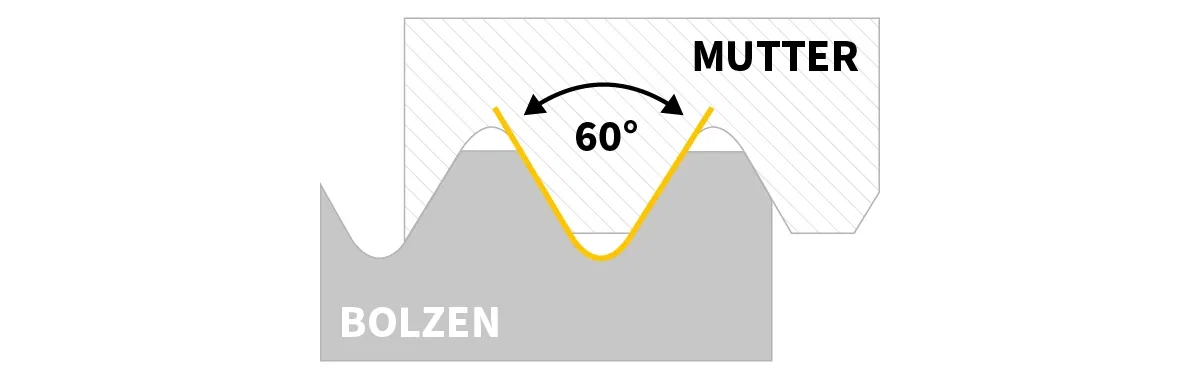

The inch-based thread from the British Cycle Engineering Institute (C.E.I.) is the predecessor of the British bicycle thread BSC. The flank angle of 60° was retained, which still distinguishes BSC from other British thread types today.

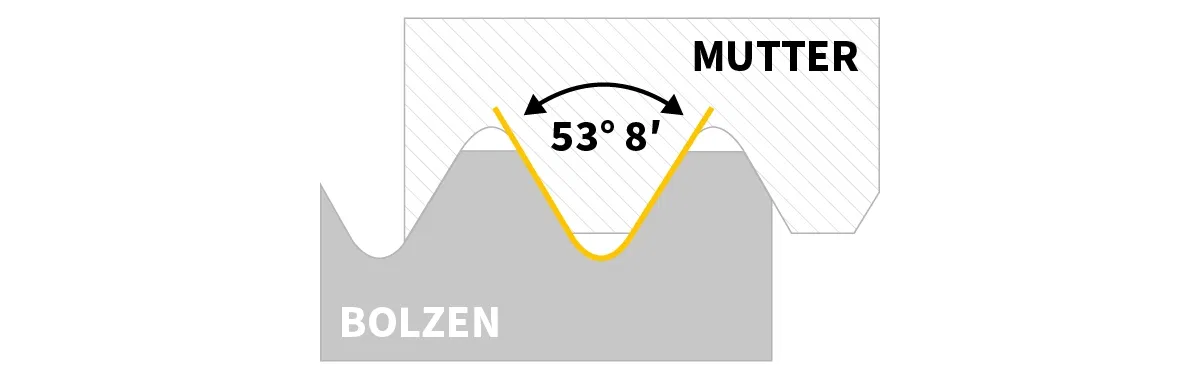

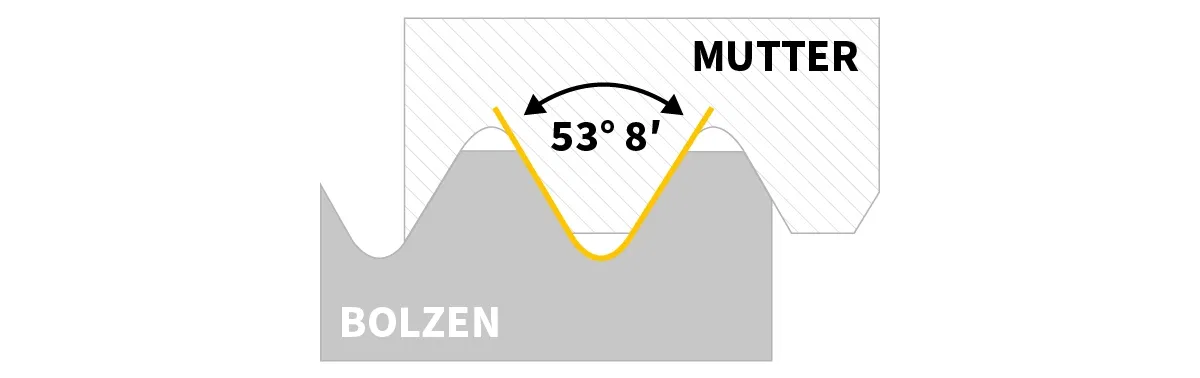

Löwenherz Thread

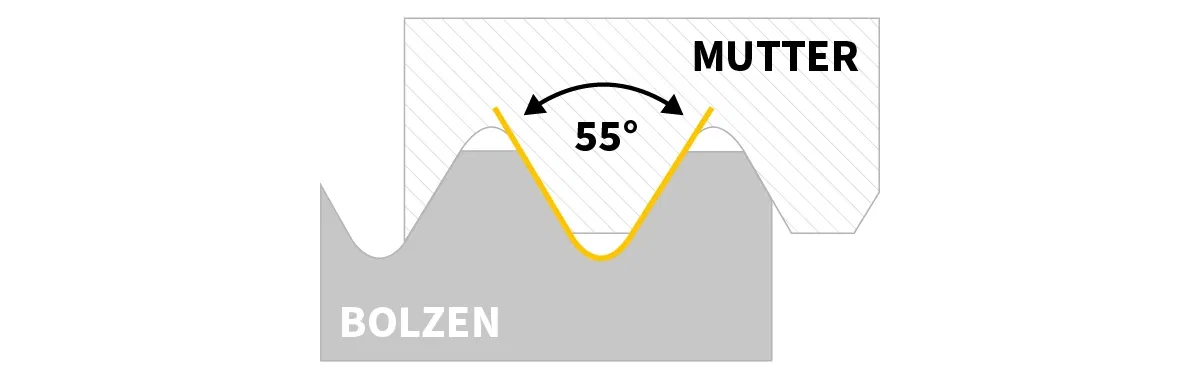

The Löwenherz thread was mainly used in precision mechanics during the first half of the 20th century. It is named after the German physicist Leopold Löwenherz, one of the pioneers of thread standardization in Germany. This metric thread has a flank angle of 53° 8′.

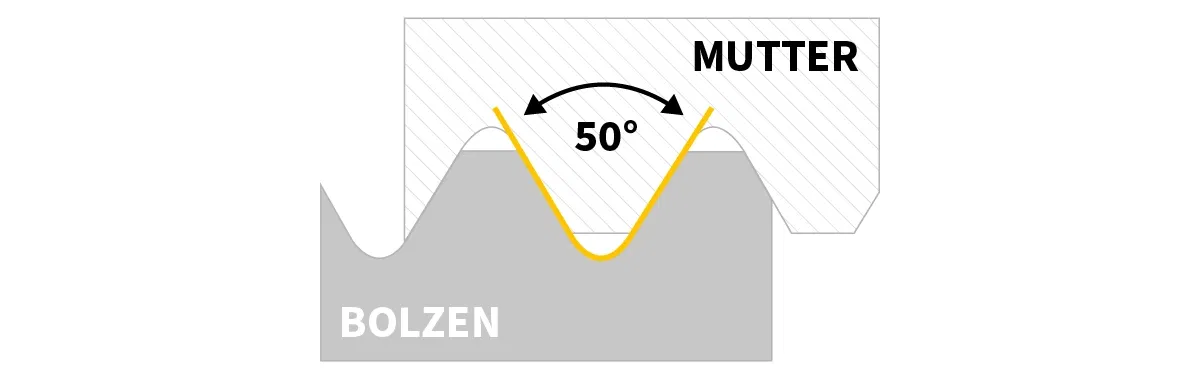

Bodmer Thread

Also from the field of precision mechanics is the Bodmer thread by Swiss mechanic Johann Georg Bodmer. It is a metric thread with a 50° flank angle. Thread sizes are indicated by the outside diameter and the number of threads per 25 mm (note: not per inch, which would be 25.4 mm).

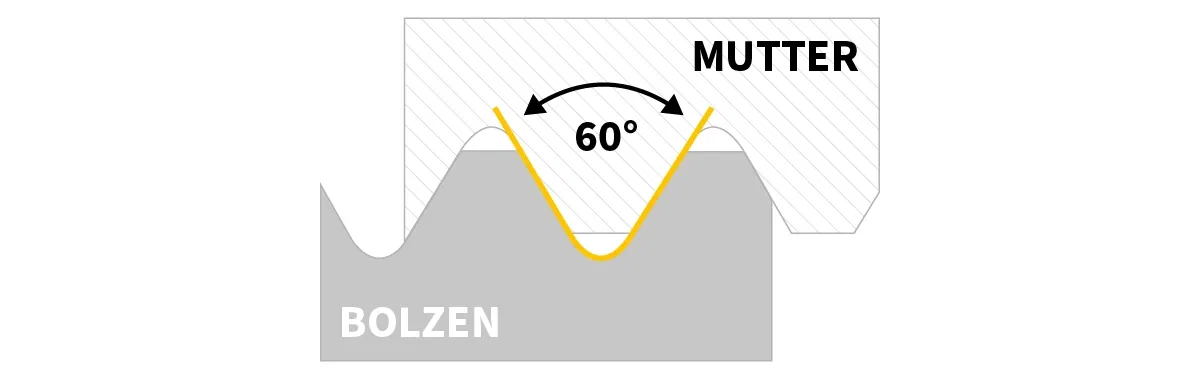

French Thread / S.I. Thread

Despite its name, the French thread was also used in Germany in the first half of the 19th century. It is also referred to as the SI thread (Système International). It’s a metric thread with a 60° flank angle and, as seen in the thread table, is the direct predecessor of the metric ISO thread.

VDI Thread

The VDI thread was developed by German engineer Karl Delisle, who presented his design to the Association of German Engineers (VDI), from which the thread got its name. Its flank angle of 53° 8′ matches that of the concurrently developed Löwenherz thread.

Ducommun Steinle Thread

The Ducommun Steinle thread is an internal thread standard from the Ducommun workshops in Alsace, which belonged to the German Empire in 1873. It’s a metric thread with a 60° flank angle. The diameter range is striking, spanning from 3 mm to 80 mm outer diameter.

Hamann Cartridge Thread

A particularly interesting case is the Hamann cartridge thread. It was used for a long-forgotten manufacturing method for threads on a cartridge lathe. There is no fixed outer diameter, but the pitch is given in threads per inch, placing it among inch-based threads.

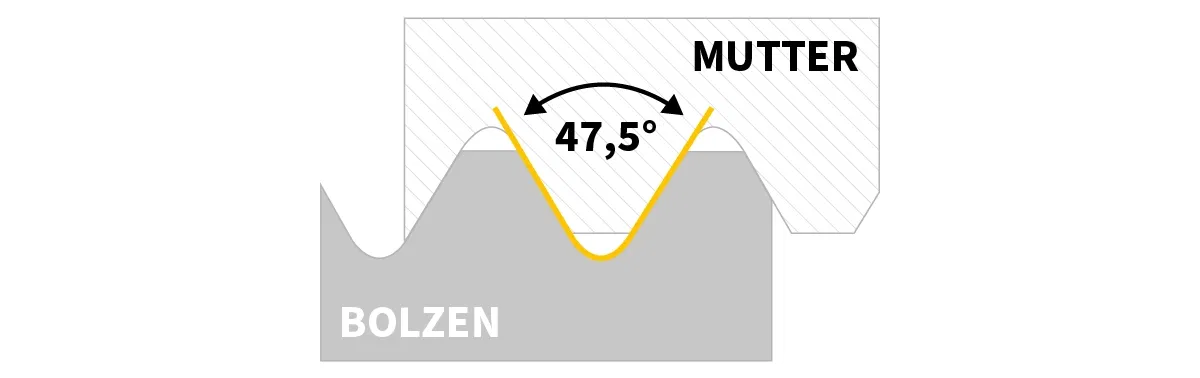

Thury Thread

The Thury thread was developed in the late 19th century by Marc Thury for the Swiss watch industry and was widely used for many decades. It’s a metric thread with a 47.5° flank angle. The dimensions were later adopted for the British Association thread (BA), which eventually overtook the Thury thread and is still used today in areas such as model building.

Sellers Thread

In the U.S., engineer William Sellers is considered a pioneer of thread standards. He developed the Sellers thread in the 1860s, and about 20 years later, it had become the national standard. It’s an inch-based thread with a 60° flank angle and a pitch given in threads per inch. It is the predecessor of the modern UN thread.

Living Fossils: Whitworth Thread and PG Thread DIN 40430

The thread types introduced above are no longer in use today, having been replaced or evolved into modern forms. But some thread types from the 19th century have survived to this day.

The most prominent example is the Whitworth thread. British engineer Joseph Whitworth is considered the father of thread standardization. And he must have done a good job because the thread named after him is still used in the UK today in the form of the British Standard Whitworth (BSW) and British Standard Fine (BSF). You might even encounter it in Germany as a Whitworth pipe thread—a true living fossil!

Slightly less glamorous but still noteworthy is the steel conduit thread used in electrical installations. Technically, it was replaced by a new standard in the early 2000s and is no longer used for new installations—but it still plays a role in repairs and the use of old components.

Working with Historical Thread Types: Problems and Solutions

If you're tinkering with old telephones or sewing machines and come across a historical thread type, you’ve got a problem. While our overview and thread tables help you identify the thread, how can you repair it? You’re unlikely to find thread tools for these standards, and hunting down ancient fastening screws on eBay is rarely successful.

For one-off cases, you might try recreating the thread on a lathe. This certainly requires finesse and skill, especially with small thread sizes. If you regularly work with specific historical threads, consider a custom-made solution!

At BAER, we are happy to help and will work with you to design the perfect tap for your project. Contact us anytime by phone or via our contact form and together we'll find a tailored solution for every challenge. We look forward to your inquiry!