How are thread standards actually created?

We all know what thread standards are. Each thread standard brings together a series of dimensions that precisely define a thread profile. This means that results are reproducible and components are interchangeable, which makes everyday work much easier. But have you ever asked yourself who exactly determines what is included in a thread standard? We think that to be able to trust a standard, you should at least have an idea of how it came about. That's why we've set to work and compiled everything you need to know about the development of thread standards in this blog post.

A look at the history of thread standards

Before we turn our attention to the current situation, let's take a brief look at the past. At the beginning of the 19th century, every thread was still unique and screw and nut formed an inseparable pair. Before the industrial revolution, this was perfectly adequate. But with the advent of mass production, more flexibility was needed and the idea of the thread standard was born. The range of thread standards continued to grow, from factory standards to national standards and today's international standards. The official year of birth of the modern thread standard is dated 1841 and the British engineer Joseph Whitworth can call himself the originator.

This is how the standardization process for thread standards works

Even if you may have been annoyed by thread standards in the past, their purpose is to make work easier. This intention is also reflected in the standardization process for thread standards. It should be as practical as possible and ideally involve the general public.

In order to initiate a new thread standard, a standard application must first be submitted. In principle, anyone can do this; you do not need any special prerequisites. However, the relevant standardization institute will check whether there is actually a need or whether there is already a suitable thread standard for the case in question.

If the application for a standard is accepted, a committee meets to prepare a first draft of the thread standard. This committee is made up of experts from all possible specialist groups affected by the thread standard. On the one hand, these are scientists and engineers, but also future users of the thread standard such as manufacturers or craftsmen. This ensures that theory and practice go hand in hand in the development of the thread standard.

Once the draft thread standard is complete, it is made public and anyone interested can view it and give their opinion. In this way, criticism and suggestions for improvement can be incorporated directly, which has a positive effect on the subsequent acceptance of the new thread standard in the market.

The suggestions received are reviewed and either discarded or incorporated into a new draft of the thread standard. This is then released to the public for criticism. This creates a productive cycle that can extend over several cycles until the number of suggestions for improvement eventually decreases and the draft is considered satisfactory.

This final draft is then shaped one last time and finally published as a finished standard. However, this does not mean that the new thread standard is now valid for all eternity. It is reviewed every five years at the latest and updated if necessary. Obsolete thread standards can also be completely withdrawn.

These are the most important standardization institutes

The standardization institutes therefore play a key role in the development of new thread standards, but they do not simply specify standards, but are very keen to ensure broad acceptance. Each country has its own standards organization. However, three institutes are particularly important for your work with threads.

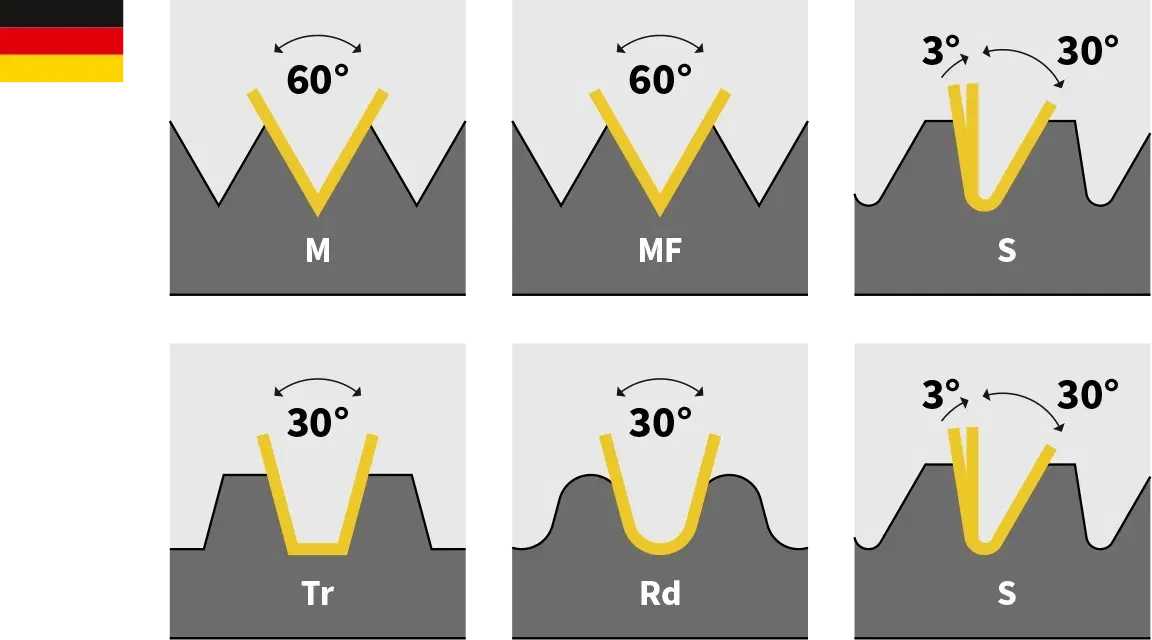

Thread standards of the German Institute for Standardization (DIN)

You know the DIN not only from thread cutting, but also from printer paper or any other area of your private and professional life. Of course, you will also find thread standards like sand by the sea. The best known of these are undoubtedly DIN 13-1 for the metric standard thread or DIN 13-2 to 13-11 for different variants of the metric fine thread. However, the trapezoidal thread DIN 103, the knuckle thread DIN 405 or the saw thread DIN 513 are also well-known outgrowths of the German Institute for Standardization.

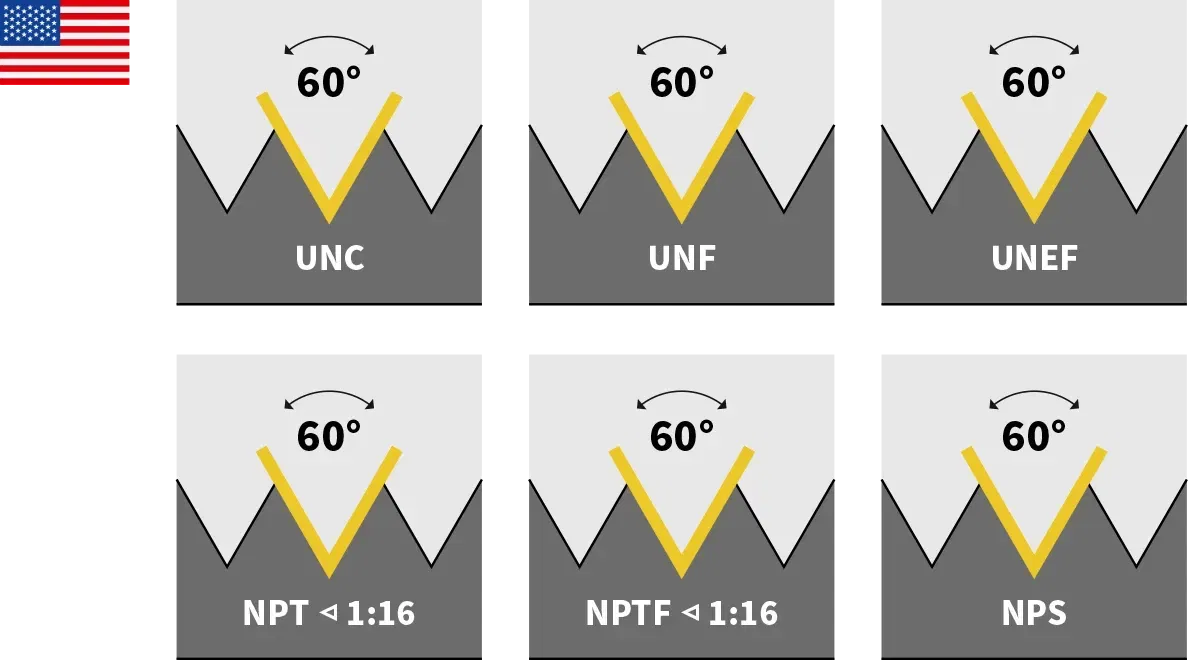

Thread standards of the American National Standards Institute (ANSI)

The American equivalent to our DIN is the ANSI. Here you will find all thread standards of the Unified Thread Standard such as the UNC, UNF and UNEF thread. And the American pipe thread types such as the NPT or the NPTF are also standardized according to ANSI.

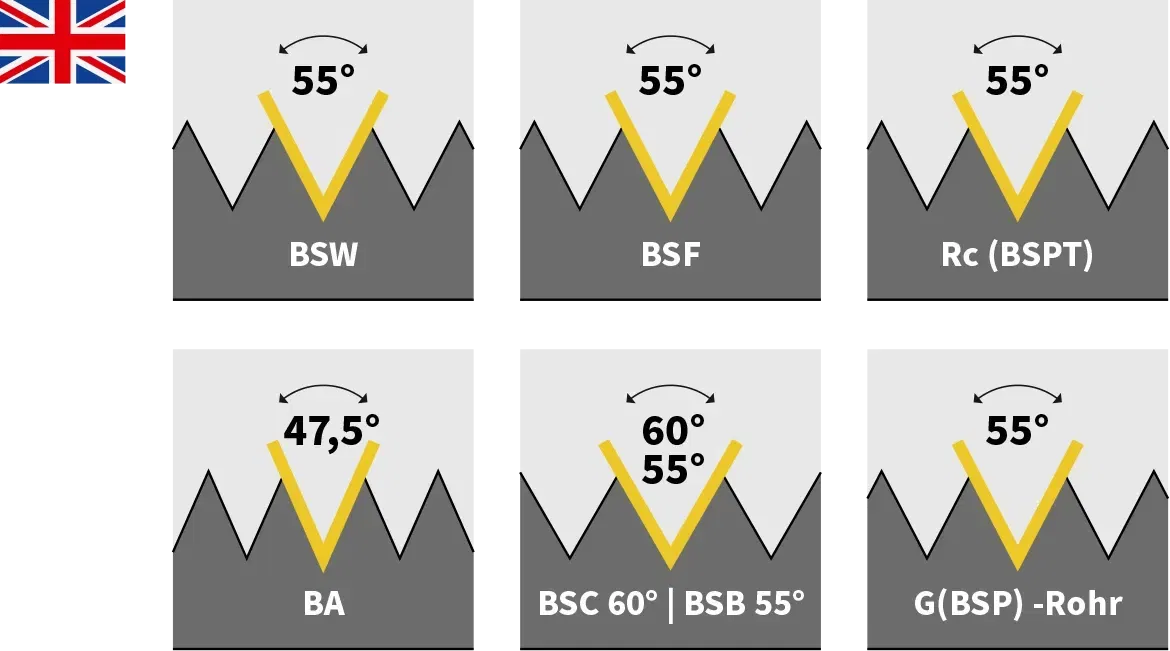

Thread standards of the British Standards Institution (BSI)

Finally, there is the British equivalent, the BSI. The most prominent representative is the British Standard Whitworth Thread (BSW) which started in 1841 and was "adopted" by the BSI after its foundation with the BS 84 standard. Based on this thread standard, many other threads followed, such as the BSF and the BSP.

The role of the International Organization for Standardization (ISO)

Perhaps you've been wondering all this time when ISO will actually come into play. After all, we live in times of globalization, in which national standards are no longer sufficient to ensure comprehensive interchangeability. The ISO develops international thread standards in a process that is basically the same as described above. National thread standards can be proposed for inclusion in the international body of standards. And vice versa, international thread standards can be included in the national body of standards. You can recognize these cases by the fact that more than one abbreviation of a standardization organization appears in the name of the standard, such as DIN ISO.

Now you know where thread standards come from. But do you also know where you can find taps for all common thread standards? At BAER in the online store, of course. And if you have any questions about DIN, ISO or any other thread machining topic, please contact our friendly customer service team!