Machining Demanding Materials Like Aluminum: Tools and Techniques

If you keep encountering seemingly inexplicable problems that can't be resolved, take a closer look at the material you're working with. The physical and chemical properties of a material have a significant impact on machining and should never be underestimated.

Whether you're milling, drilling, or cutting threads – it makes a big difference whether you're working with aluminum or titanium. Each material requires suitable tools, from aluminum cutters to high-performance drills.

What Types of Materials Are There?

The number of different materials is almost unmanageable, as every substance that can be shaped or machined in any way falls into this category. Materials can occur naturally or be artificially produced. Sometimes they are in their raw form, but often their properties are enhanced, modified, or optimized by additives or special processing.

Since this blog focuses on thread machining and the tools required for it, we can limit the relevant materials to metals in this context.

Different Metals and Their Machining

Metals can be divided into ferrous and non-ferrous metals. Ferrous metals include steel and its many variants. Non-ferrous metals include materials like copper, aluminum, or titanium. The properties of a metal always depend on its alloy.

Machining Steel and Stainless Steel

Steel is frequently machined and is of great importance when it comes to cutting threads. Stainless steel in particular presents several challenges. Most stainless steels are tough and require a highly durable tap, as the cutting process can generate high temperatures. Drilling stainless steel without annealing works best with a special coating containing titanium components or with a surface treatment such as vaporizing.

Challenges in Machining Aluminum

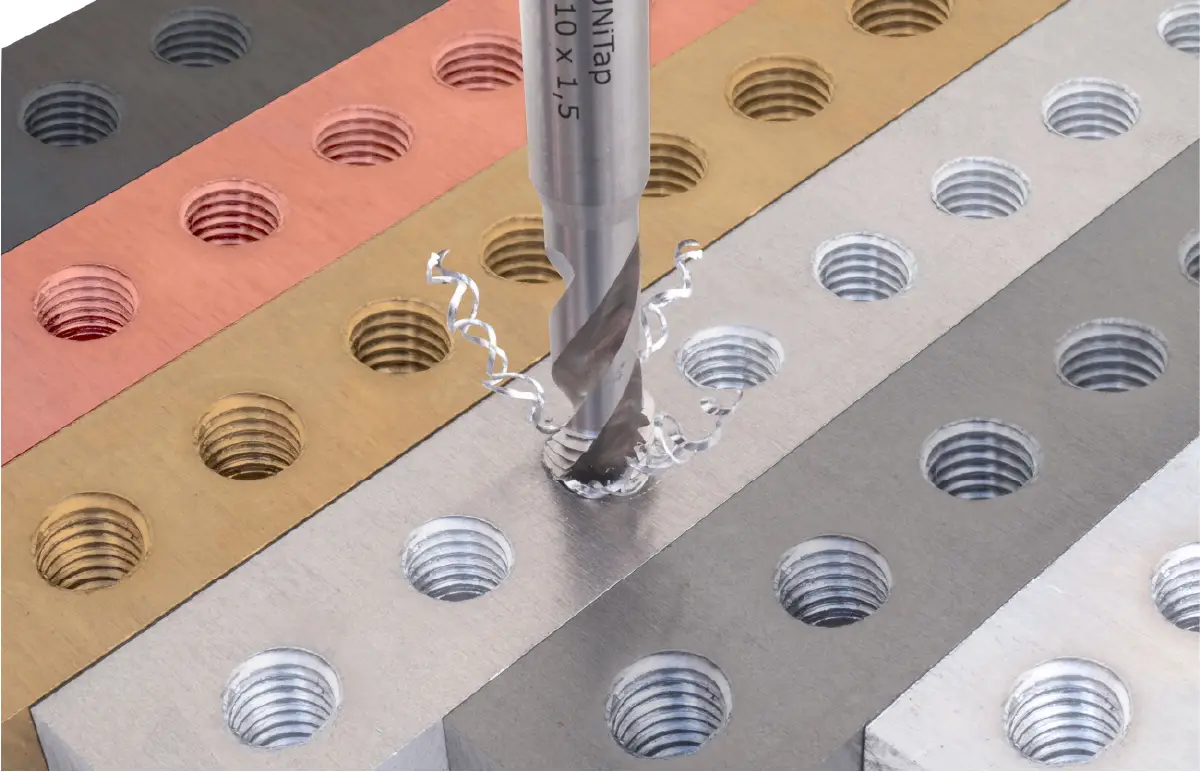

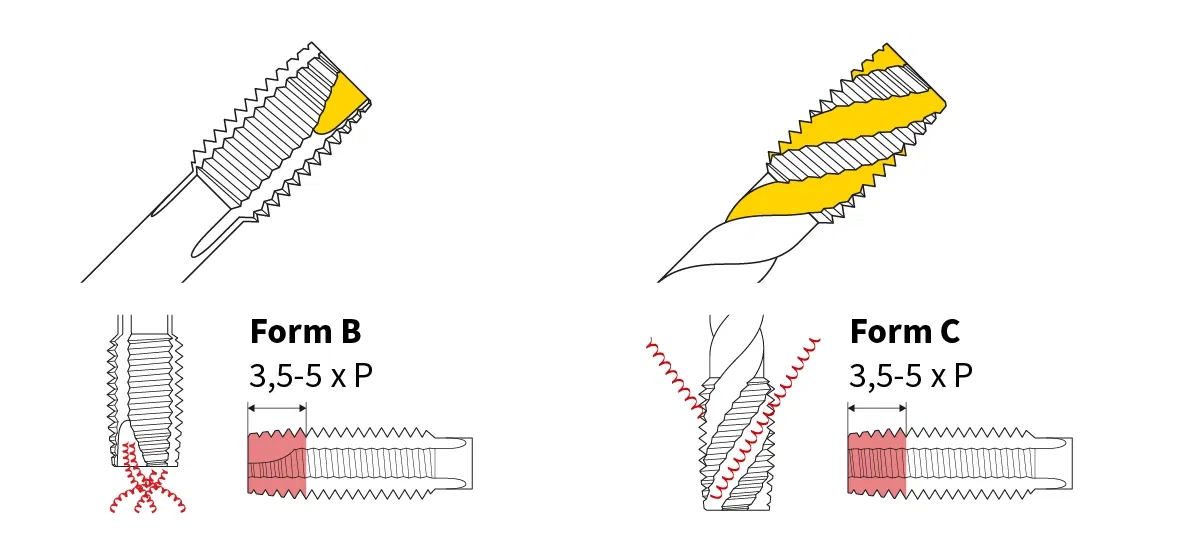

Aluminum is a lightweight metal and is often used in industries where weight matters. Many components in automotive manufacturing are made of aluminum. Most aluminum alloys are easy to machine; chip formation tends to be the bigger issue. Chips should be as short and compact as possible, but aluminum tends to form long chips. Therefore, selecting the right tap design is essential for smooth chip evacuation. Form B with a chamfer is well-suited for through holes, while right-hand spiral flutes are crucial for blind holes to push the chips upward and out of the hole.

To increase the performance and stability of threads in aluminum, it’s recommended to use thread inserts. This improves pull-out strength in light metals and allows you to benefit from aluminum’s advantages without dealing with its disadvantages.

Requirements for Titanium and Exotic Metals

Titanium also belongs to the group of lightweight metals, but it is the heaviest metal in this category. It combines low weight with high strength and is correspondingly difficult to machine. You’ll need a robust tap that can handle titanium. The preferred tool material is cobalt-alloyed high-performance high-speed steel (HSSE).

Other metals that require special tools include copper, brass, or special nickel-based alloys such as Inconel.

Geometries, Coatings, Surface Treatments: The Role of Tap Properties

There are three factors that influence the efficiency of your tools and determine how well they are suited for a material:

Base Material

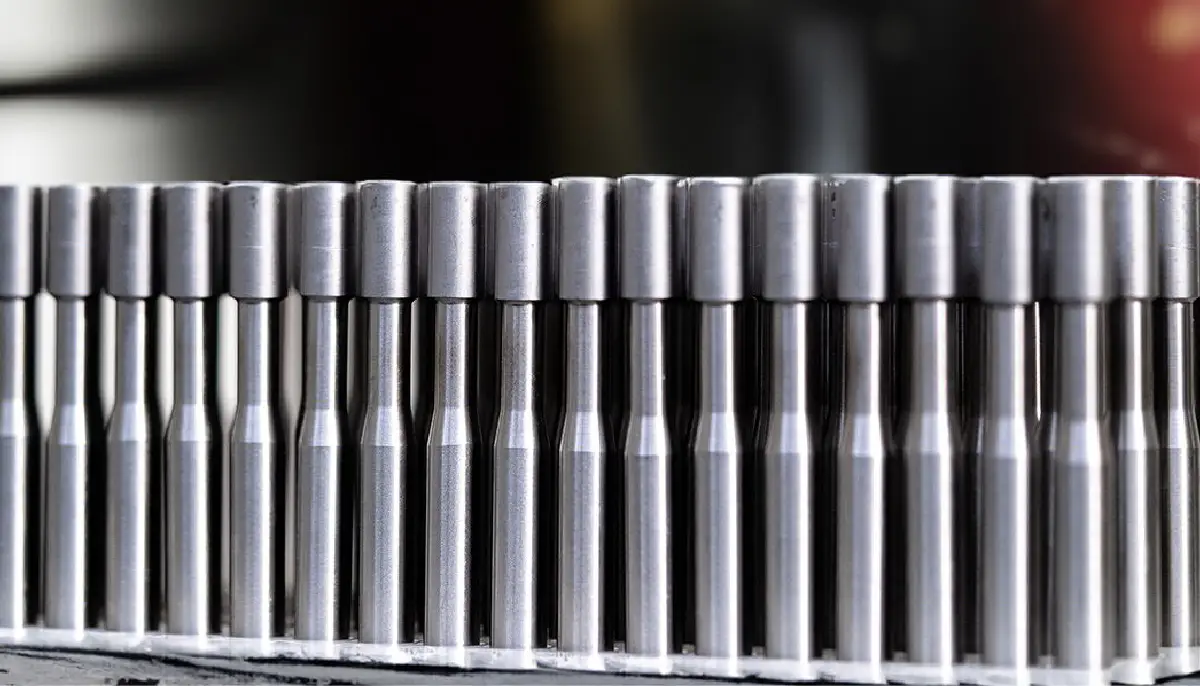

Cutters for aluminum or twist drills for stainless steel – beyond price and obvious factors like the correct diameter, the tool material should be the central factor when choosing your tools. HSS steel is usually a solid choice.

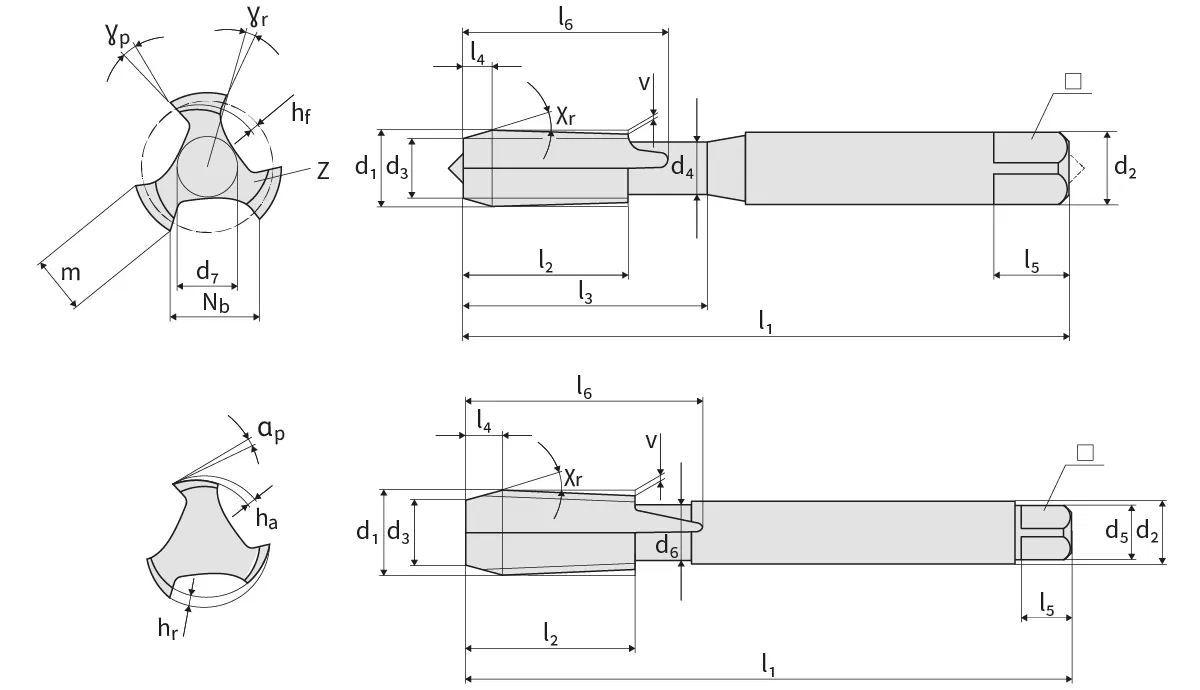

Geometry

The geometry and general design of a tool also have a major impact on thread quality and cutting performance. The rake angle is particularly important, as it determines the shape of the resulting chips. A strong shank can provide the stability needed for tough cutting conditions.

Coating

The properties of a tap can also be significantly influenced by surface treatments and coatings. Coatings come in countless varieties across all industries – from extremely hard DLC coatings to PTFE coatings, known from non-stick pans. For threading tools, the most relevant coating types include:

- TiN (Titanium Nitride)

- TiCN (Titanium Carbonitride)

- TiAlN (Titanium Aluminum Nitride)

These coatings influence properties such as hardness and toughness, temperature resistance, and wear resistance.

Which Tap for Aluminum and Other Materials?

In most cases, you’ll be working with unalloyed or low-alloy steels – here, a standard tap will do the job. But as soon as you’re dealing with stainless steel or materials with challenging chip formation, it’s worth taking a closer look at the label. It will indicate which materials the tool is suitable for.

For stainless steel, tools with a TiCN or TiAlN coating are ideal. Vaporizing also reduces friction and makes work easier. For long-chipping materials like aluminum, geometry is especially important – particularly for blind hole threads. Taps with a steep right-hand spiral help remove long chips against the cutting direction.

If you want to make things especially easy, just visit our BAER Online Shop. The tool finder on the homepage and the detailed product information for each item make selecting the right tool a breeze. And if you have any questions, our friendly and knowledgeable customer service team is always happy to help.