Measuring threads - That's what counts!

Have you ever replaced an old component and couldn't remember the thread size you used? There are many reasons to measure threads. And almost as many techniques and methods to accomplish this task. We'll shed light on the subject and explore the complex topic of measuring threads together.

As a DIY enthusiast or craftsman, the most common scenario you'll encounter is this: You need to purchase a replacement screw, pipe, or something similar and want to determine which component you need. Fortunately, it's not that complicated. We'll explain how to accurately measure threads for home use at the end of this blog post. But first, let's look at some other occasions when thread measurement becomes necessary. To do this, we'll first clarify some technical terms.

Testing, measuring, or gauging?

In everyday language, terms like measuring, testing, and determining are often used interchangeably and mixed up. So, to avoid any confusion and to ensure you measure threads correctly, let's first address some general points on this topic.

Testing, as a general term, refers to the process of determining whether a test object possesses certain characteristics. This can be further divided into subjective and objective testing.

During subjective testing, you visually inspect the test object and may also physically touch it. This way, you can immediately identify significant damage or severe deviations from the norm. In other words, if the screw is broken, you don't need any other tools to determine that.

Objective testing, on the other hand, can still confirm the alignment with the expected characteristics where human sensory perception might fall short. However, this requires the use of tools. Thread measurement falls into this category. Yet, we still need to make a further distinction: Measuring or Gauging?

Measuring threads and gauging differ in the result they produce. When you measure a thread, you get a measurement value. On the other hand, when you gauge a thread, you only get an evaluation of whether the test object is good or defective. Gauges are mostly used in industrial production. The goal is to determine whether the tools being used, due to damage or wear, might no longer be within standards. Thread measuring is common in both professional and household settings.

How the professionals do it

In the industry and crafts, precision is key. This is even more the case when measuring threads. Even minor deviations can have major consequences, and cross-threaded or worn threads pose both a human and financial risk. Thus, thread measurement plays a central role.

Threads are measured:

- on the component itself

- using the thread gauge

- on the thread cutting tool

In professional settings, thread measurement is less about determining a thread. Instead, it ensures that standards are met, tools function as expected, and, importantly, that the measuring tools themselves are reliable. The methods used are consequently more precise and involved than those used by DIY enthusiasts.

Measurement Uncertainty

As often is the case, when measuring threads, it's essential to know one's limitations. Humans aren't machines, and many factors play a role, meaning a measurement can never be 100% accurate. Therefore, measurement uncertainty must always be taken into account. Complex formulas, which consider all influencing factors, are used for this.

Influencing factors include:

- Measuring conditions

- Human factor

- Measuring tools

- Test object

- Measuring method

A highly motivated, experienced employee might get different results on a hot day using a worn-out measuring tool than an apprentice might in the winter. To account for this, the measurement uncertainty is calculated before measuring the thread.

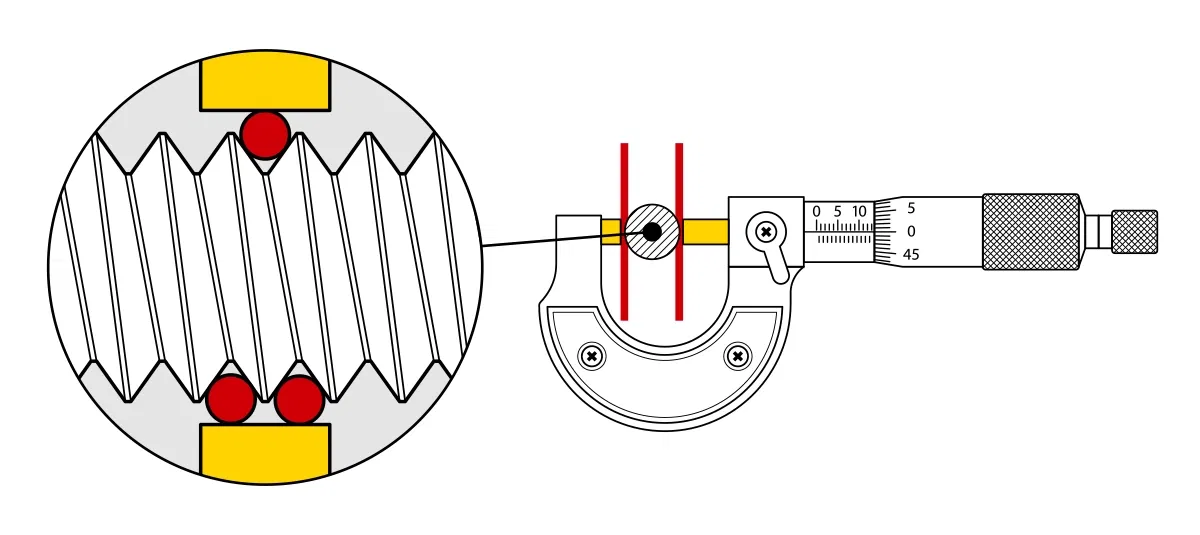

Measuring threads using the Three-Wire Method

In professional settings, the flank angle of an external thread is usually determined using the so-called Three-Wire Method, which provides particularly precise results. To measure a thread with this method, three measuring wires are placed into the thread grooves so that two wires are side by side and the third is on the opposite side. The wires are held in position with flat probes, and the distance between the probes allows the flank diameter to be calculated, and the thread to be measured.

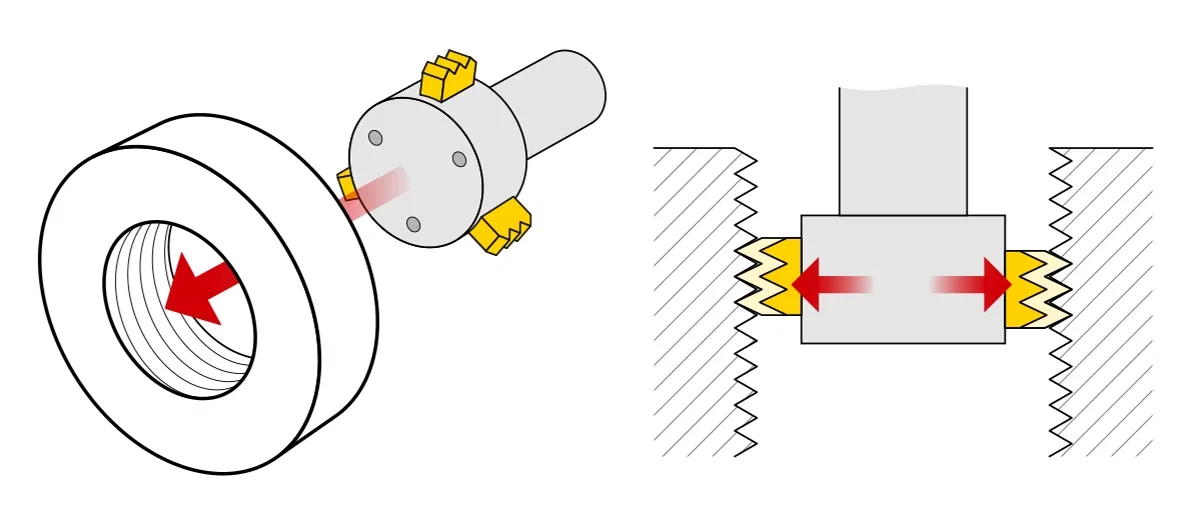

Measuring threads using the Three-Point Method

The Three-Point Method is the equivalent of the Three-Wire Method. It is used for measuring internal threads. Instead of wires, test needles are used that press from the inside into the thread grooves.

Measuring threads on thread cutting tools

There are some specifics when measuring threads on thread cutting tools. Due to their unique design, there are many more measurement values that need to be determined, such as the lead-in chamfer and the spirla flute angle. Thread measuring screws assist in determining the flank diameter. What, where, and how things are measured, however, is usually left up to the manufacturer.

Determining threads for household use

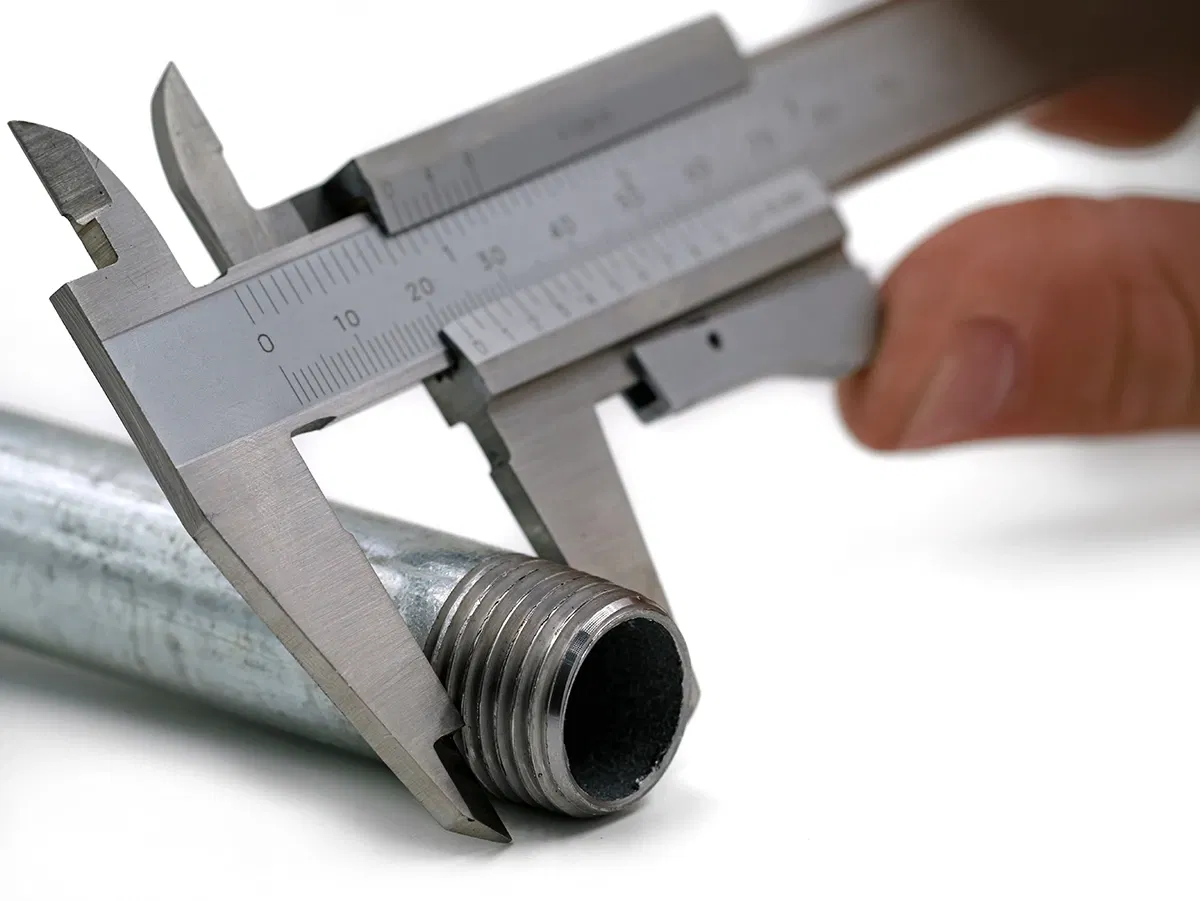

If all this sounds rather complex, we have good news: To simply determine which screws Uncle Manfred used during the bathroom renovation in the 90s, you need to expend much less effort to measure the thread. All you need is a caliper and a thread pitch gauge.

A caliper is a common measuring instrument for precisely measuring lengths, which you probably already have in your toolbox. A thread template consists of a set of metal blades with teeth, each corresponding to a thread standard.

When measuring a thread, first determine the nominal diameter of the test piece using the caliper. It's best to measure at two points to rule out the possibility of a tapered thread. Both measurements should match.

Now take out your thread pitch gauge and match its blades to your thread until one fits perfectly. If you know you're dealing with a standard metric thread or a fine thread, you can simply read the pitch from a table based on the nominal diameter and only use the template for confirmation.

Done! Your thread is now correctly measured, and you can start looking for the right tool - best done at the online shop of Screw Tap Manufacturer BAER. They offer everything related to thread cutting. Check it out!