Movement thread: examples, types and differences

Do you think of screws when you hear the term "thread"? If so, you're not alone. Many DIY enthusiasts would relate. Indeed, screws and nuts are the most notable examples of this category, and most of us encounter or use these essential components daily. However, it's often overlooked that threads can serve purposes beyond just holding our wardrobes together. There are threads specifically designed for continuous motion!

Let's delve deeper into this intricate topic. We'll discuss the differences between fastening and motion threads, showcase the most common types, and present practical examples of both, enabling a clear understanding of the theory.

Distinguishing Fastening Threads from Motion Threads

The primary distinction between fastening and motion threads lies in their respective application areas. A fastening thread's purpose is, as the name suggests, to fasten. On the other hand, a motion thread serves a different function - converting rotational motion into axial movement, and occasionally the reverse. These two thread types are designed according to their roles and thus have distinct key features. Let's examine them closely:

1. Profile

Fastening threads typically have a sharp profile, ensuring a firm grip. However, motion threads come in various profile shapes, each suited for specific applications. The most common are the trapezoidal thread, round thread, and buttress thread.

2. Pitch

Fastening threads generally have small pitches, contributing to the secure positioning of the components. In contrast, motion thread pitches vary based on their application. Some might have very high pitch values, allowing more distance to be covered per rotation.

3. Self-locking

Self-locking is determined by the thread's pitch and another factor called the friction coefficient. In many fastening threads, self-locking is not just desired but essential. Without it, screws could loosen by themselves. In contrast, the self-locking attribute in motion threads varies with the type of thread. Some, like steep threads, might not possess any self-locking property.

4. Number of Starts

The number of starts refers to the number of thread helices. Typically, and in most fastening thread types, there's just one helix spiraling around the bolt. However, especially in motion threads with a large pitch, there can be two or more helices. This design allows for more distance covered per rotation and reduces wear in parts like spindles.

Fastening Threads: Examples and Applications

We've examined the differences between fastening and motion threads. So, what do these distinctions mean in practice?

A universally known example of a fastening thread is the metric regular thread with its sharp profile and a flank angle of 60°, commonly found in screws and nuts. Similarly, the metric fine thread is another fastening example, suitable for adjusting screws due to its fine-tuning capability.

International thread standards, like the American Unified National threads, offer many examples of fastening threads, with applications extending beyond just screws. For instance, the Whitworth pipe thread, used in plumbing, is a classic fastening thread type.

Motion Threads: Examples and Applications

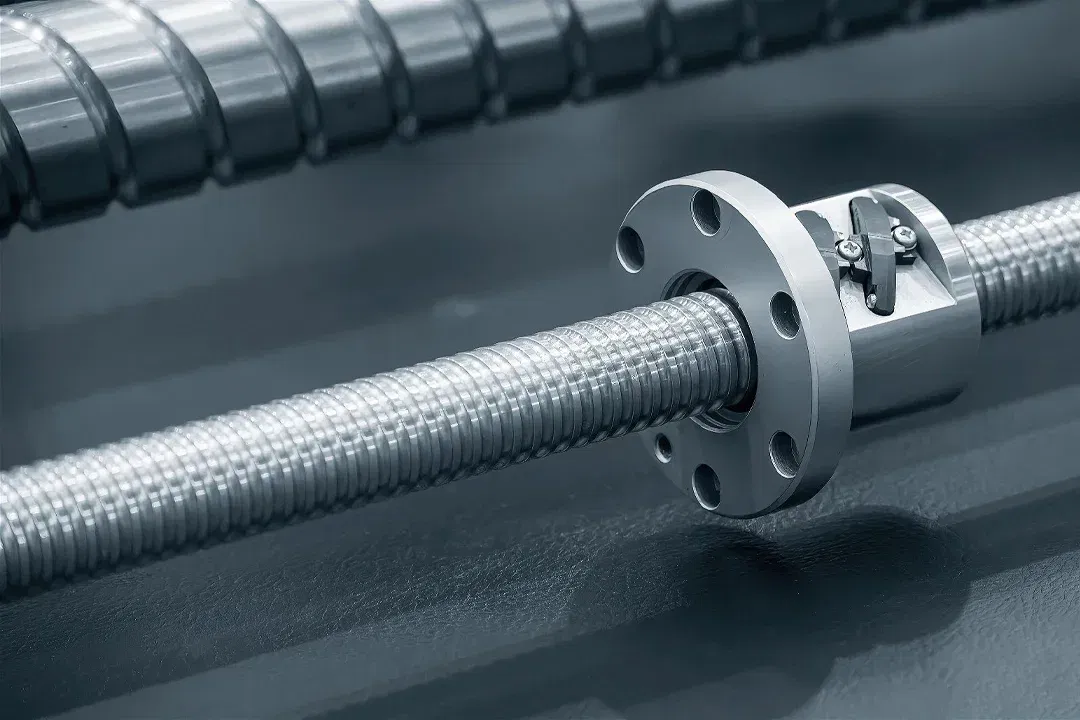

There are numerous motion thread types, each tailored for specific purposes. The commonality is their ability to convert rotational movement into axial movement.

Trapezoidal Thread

The trapezoidal thread is perhaps the most familiar motion thread, identifiable by its trapezoid-shaped profile. If you've seen a machine tool, you've encountered this thread, which facilitates feed movement in machine tools such as lathes. Additionally, it's used for adjusting movements in lifting systems or forklifts and even drives assembly lines. A less industrial example? Your workshop vice operates thanks to the trapezoidal thread.

Rd Knuckle Thread

The knuckle thread stands out for its resilience to dirt and damage due to its shape. Therefore, it's favored in rugged conditions, such as on the coupling spindle of railway wagons. Occasionally, its sturdy nature also makes it suitable as a fastening thread.

Buttress Thread

Named for its unique, asymmetrical profile resembling saw teeth, the buttress thread is ideal for high, one-sided loads. It's commonly found in spindle presses and hydraulic presses. Moreover, lifting spindles in lifting systems, especially in mining, employ this thread. Even collets in turning and milling machines use buttress threads.

Other Motion Thread Examples

Numerous other motion threads exist, designed for various purposes. For example, steep threads aim to convert minimal rotational motion into maximum axial movement. Conveyor threads aid fluid circulation. The ACME thread, an American counterpart to our trapezoidal thread, is employed in mechanical presses, pumps, extruders, and even airplane flaps.

As you can see, the types and applications of fastening and motion threads are vast. At BAER's online store, your thread tool manufacturer, you'll find threading tools for every discussed fastening thread type, such as the metric regular thread, and all motion thread examples like the trapezoidal or knuckle thread.