Old but still highly topical: the worm gearbox

It is not entirely clear how old the worm gear actually is. But it clearly dates back to pre-industrial times and is still used today. So the worm gearbox must be doing something right.

Let's take a look at what exactly. Of course, we are particularly interested in the role played by the thread. But you can also find out about the general design of this gearbox and where exactly it can still be found today in this article. So let's get straight to it and start from the beginning!

A brief look at history: how old the worm gear is

Once again, it is the greek universal genius Archimedes who is said to have had a hand in the invention of the worm gear. However, there is no absolute proof of this. Later, the worm gear appeared again in the late Middle Ages. First in India in the 13th and 14th centuries, then also in Europe. Designs for constructions using worm gears can be found in the works of Leonardo Da Vinci and Albrecht Dürer, for example. In the 19th century, it was finally popular in shipbuilding and vehicle technology.

Worm shaft and worm wheel: This is how the worm gearbox is constructed

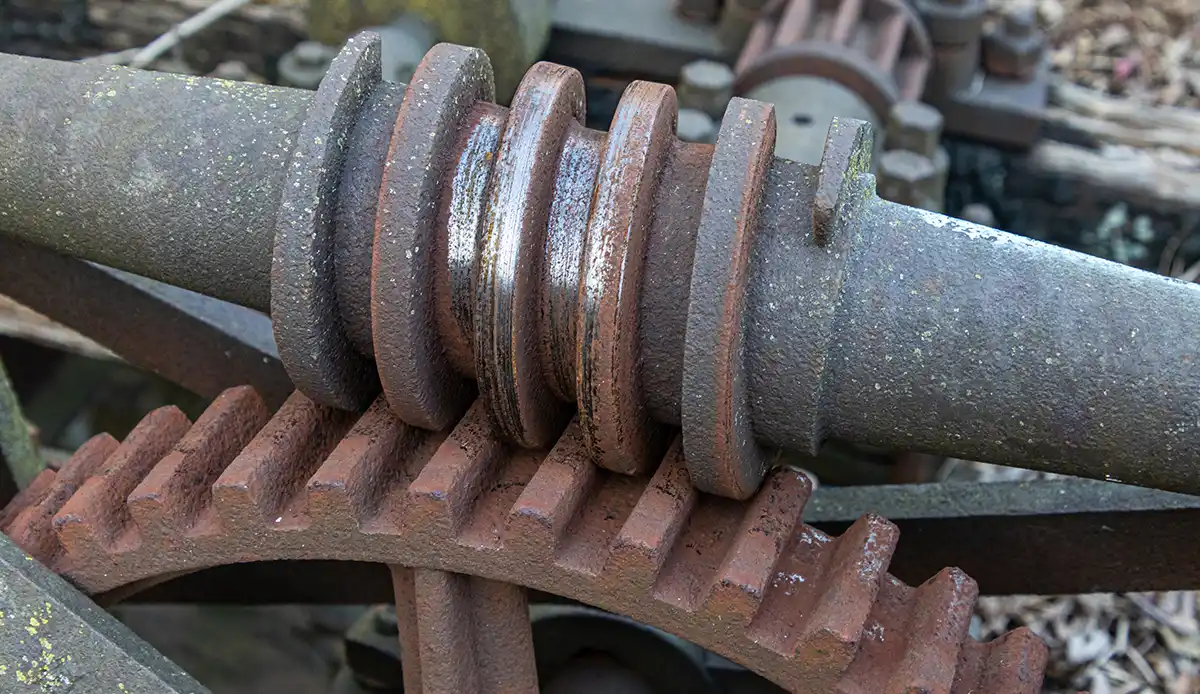

The two most important parts that no worm gearbox can do without are the worm and the worm wheel. A ball bearing is often also part of the structure and everything is housed together in a compact housing.

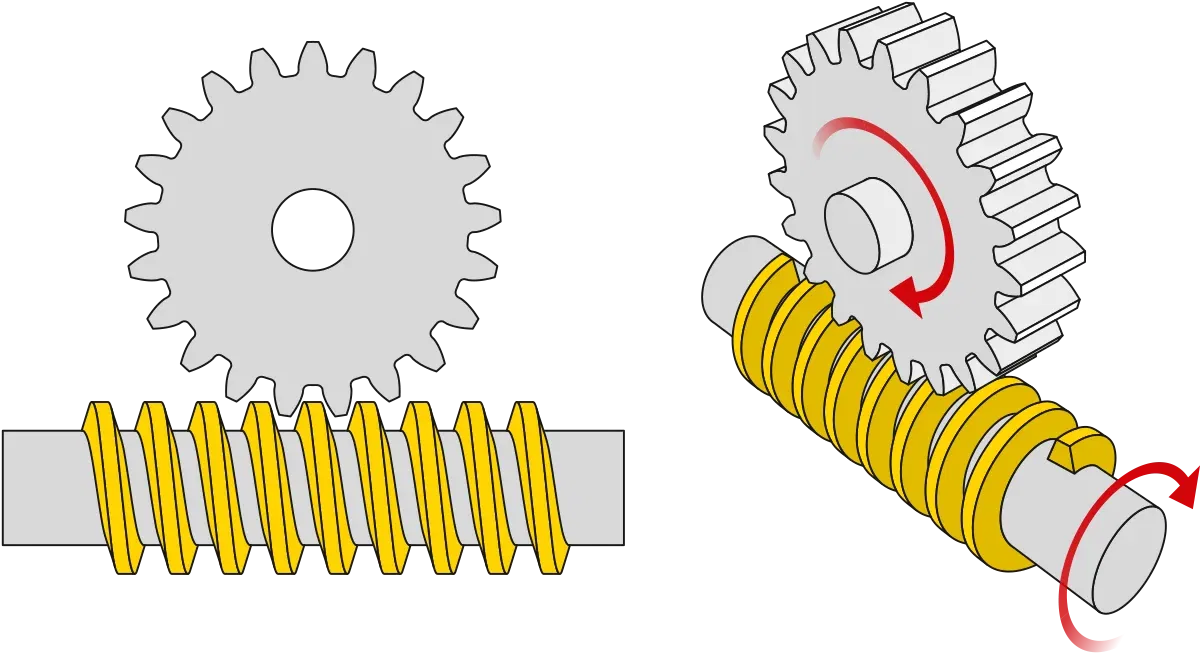

The worm is a shaft which, like a threaded rod, is provided with a thread which winds around the pin in a spiral. These shafts can also have more than one thread, in which case they are multi-start screws. Worms can also be left or right turning.

The worm wheel is basically similar to a gear wheel, but the teeth are at an angle. This allows the shaft and worm wheel to mesh. To keep friction as low as possible, materials of different hardness are usually used, e.g. hardened steel for the worm and brass for the worm wheel.

In almost all cases, the drive originates from the worm and the crossing angle of the axes is usually 90°. The worm shaft is therefore driven to rotate by a motor, engaging with the teeth of the worm wheel with its threads and thus also setting it in motion.

The properties of the worm gearbox

A worm gearbox stands out above all due to its combination of high transmission ratios and comparatively low efficiency. On the one hand, its special properties make it ideal for certain applications, but it also has some disadvantages.

What are the advantages of a worm gearbox?

The worm gearbox is characterized by high efficiency and performance and combines very precise torque transmission with low energy requirements. The high transmission ratio allows a low input speed to be converted into a high output speed. The compact design makes the use of worm gearboxes a good choice even where space is limited. The drive also runs very quietly and with low vibration.

What are the disadvantages of a worm gearbox?

Worm gearboxes can heat up quickly during operation, so care must always be taken to use a suitable cooling lubricant. In addition, high axial forces occur, which lead to high loads and must be taken into account when designing the housing.

In addition, there is often a relatively large amount of play when the worm and worm wheel come into contact. Worm gearboxes can therefore only be used to a limited extent in areas where extreme precision is required.

The self-locking feature of the worm gearbox

Another special feature is the possibility of self-locking. This occurs due to sliding friction when transmitting large ratios with low gear ratios. In these cases, it ensures greater safety and may even make a brake mechanism superfluous.

However, unwanted self-locking can also occur at high speeds, which then causes the construction to jam. This effect ensures that the gearbox only functions perfectly within a certain speed range.

Different types of worm gearboxes

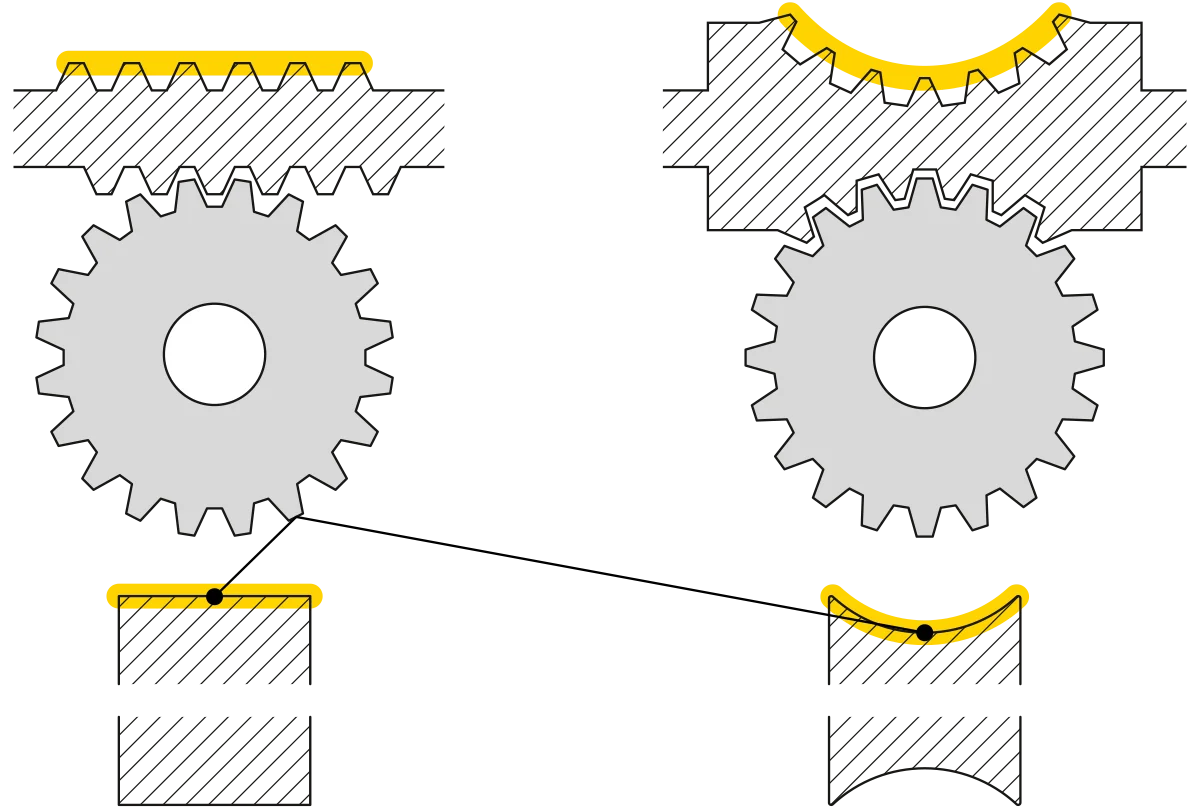

The different variants of worm gearboxes are primarily distinguished by the shape of the worm and the worm wheel. Both components can be cylindrical or globoidally curved, resulting in four different combinations. The most commonly used combination is a cylindrical worm with a globoidal worm wheel; this type is also known as a cylindrical worm gearbox.

The worm gearbox in use: This is where it is used

The possible applications for the worm gearbox are not only very numerous, but also particularly diverse. Let's start with the obvious cases. In industry, we find these gearboxes in presses and rolling mills, in conveyor systems and especially in mining.

In the past, worm gears were also widely used in shipping, where they were used to steer the rudder. The gearboxes were also frequently used in the automotive industry in the past and can still be found today, for example in the Torsen differential gear used in some Hummer and Audi quattro models.

But the worm gear also cuts a fine figure far away from large machines. It is also the mechanism used to tune stringed instruments. In this way, the rotary motion is transmitted from the so-called wing or handle to the axle to which the string end is attached. And perhaps the most beautiful application at the very end: when you turn the crank of a music box to listen to the lovely sounds, you are also operating a worm gear at that moment!

It's amazing what threads can do! If you have now acquired a taste for it, then be sure to take a look at our BAER online store. Thousands of thread machining products are waiting for you there. And if you have any questions or problems, you can contact our customer service team at any time.