Regrinding taps: sustainable & economical

Sustainability is the topic of our time. With varying levels of enthusiasm, we recycle our yogurt cups, pay extra for green energy, and donate unwanted clothes to secondhand stores rather than discarding them. However, sustainability becomes especially appealing when we can also derive a direct benefit from it. This brings us back to the subject of thread cutting.

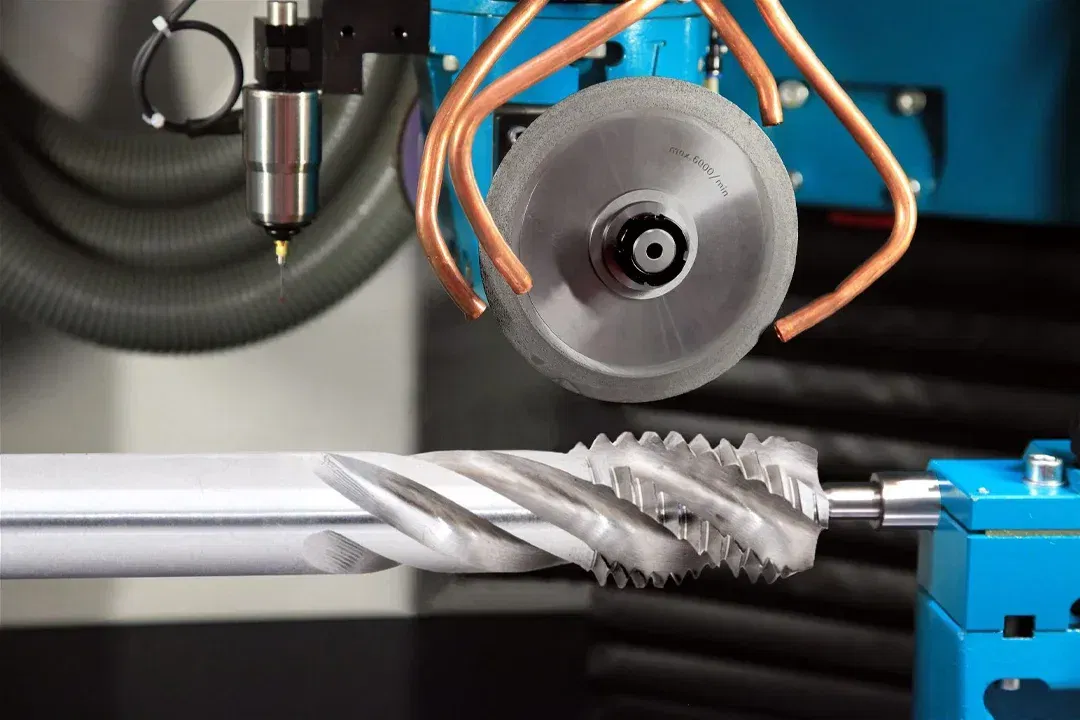

It is also sustainable to give damaged or worn tools a second chance. This conserves resources, reduces waste, and saves money! Resharpening screw taps can breathe new life into tools you might have already given up on. But be cautious before you whip out your grinding wheel: It's best to entrust this task to a professional resharpening service for screw taps. To ensure the tap remains precise and operates flawlessly after resharpening, expert knowledge is essential!

What is the Value of Resharpening Screw Taps?

A screw tap undergoes a lot in daily use. It's no wonder that over time, it might lose its original sharpness. The cutting edges wear out, and occasionally there might be more severe damages like broken teeth or cold welding, causing a change in the cutting edge's geometry. All these issues can be addressed by resharpening your screw tap.

Wear and damages can impact the quality of the threads produced. This can have significant implications, for instance, if threads are no longer cut to standard specifications due to excessive wear of the tool. If you delay the resharpening process for too long, there's also a risk of the tap breaking, which would make it irreparable and could even damage the workpiece. Resharpening screw taps not only improves the quality of your work but also saves money. Without a doubt, resharpening screw taps is a more affordable and sustainable alternative to purchasing new ones.

How to Resharpen Your Screw Tap

Resharpening screw taps requires expertise. Each tool is unique, and every case of wear or damage needs specific attention. Before any work begins, the exact damages must be identified and assessed. Screw taps are precision tools, and their original geometry should not be altered during the resharpening process. After all, you would want the reshaped tap to cut the same thread as before.

The lead and flank surfaces are the points of focus during resharpening. Here's how each step typically works:

Screw Tap: Resharpening the Lead

For blind holes, the lead usually needs to be shortened to remove wear. This is the first step. After this, the grinding wheel is aligned at the correct angle to the thread tap's axis to resharpen the lead, ensuring the proper lead clearance angle and lead diameter.

Resharpening screw taps for through holes often does away with shortening the lead. However, this means the cutting section will slightly extend, which must be taken into account during subsequent usage.

Screw Tap: Resharpening the Flank Surface

Once the lead is taken care of, the flank surfaces need attention. This step is crucial for the quality of the resharpening. The correct flank angle is vital. It must be measured directly on the tool before grinding and then checked again afterward.

Special Case: Spiral Entry Lead

Resharpening a spiral entry lead tap requires special care. Professional resharpening services for screw taps use specific grinding fixtures that can tilt both horizontally and vertically. This setup allows for accurate adjustment of both the spiral entry lead inclination and the correct spiral entry lead angle. Within the spiral entry region, the flank angle remains crucial. After resharpening, the spiral entrie's length should be about 1 to 2 threads longer than the lead.

Things to Consider When Resharpening Screw Taps

Resharpening thread taps involves a lot of nuances and challenges. It starts with choosing the right machine. There are specialized fixtures for resharpening screw taps that only require a basic tool machine. However, these are typically only suitable for the flank surfaces. A professional resharpening service for thread taps often employs modern CNC machines for added precision. The chosen grinding wheel also plays a significant role and may need treatment during the grinding process due to the stress exerted by the tap's teeth.

Other factors also come into play during resharpening. For instance, it's usually better to opt for a wet grind during the resharpening process. Feed rate and the tilt angle of the grinding wheel also greatly influence the outcome of the resharpening.

Resharpening Thread Cutting Dies

It's not only screw taps that can be resharpened, but thread cutting dies as well. They should be resharpened when showing signs of wear or when damages are observed. During the resharpening of thread cutting dies, typically, only the lead and the spiral lead are addressed. However, if required, the thread part can also be resharpened using grinding pins. The flank angle remains crucial but can be challenging to measure accurately when resharpening thread cutting dies.

If you've read this far, you're probably convinced that resharpening screw taps should be entrusted to a professional resharpening service for screw taps and thread cutting dies, like ours! Use BAER's resharpening service and benefit from our decades-long experience as a screw tap manufacturer. Fast, friendly, and competent – that's BAER. We are always happy to receive inquiries through our contact form or over the phone.