Set Screw – A Headless Screw

Anyone interested in threads is inevitably also interested in screws. After all, a screw is nothing without the thread and vice versa. But not all screws are the same. There are many different types and variants for a wide range of applications. Today, we’ll take a closer look at a special type of screw: the set screw.

The set screw is also known as a set screw or socket set screw. These rather unflattering names become clear once you take a close look at it. It does resemble a little set. This impression mainly comes from its unique shape: it has no head. Why that is, how a set screw is used, and where it’s applied — read on to find out.

What Is a Set Screw?

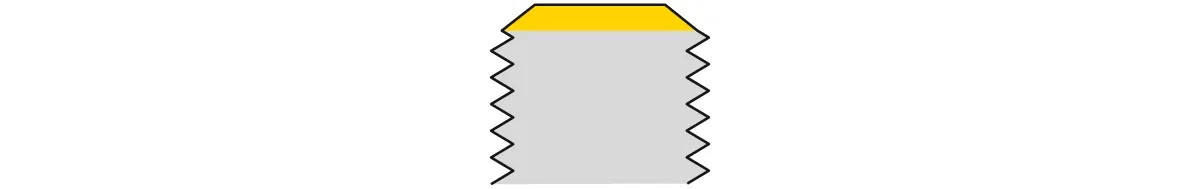

The main characteristic of a set screw is the fact that it has no head. This sets it apart from the stud screw, which can be distinguished by the presence of an unthreaded section in the middle of the shaft. In contrast, a set screw features a full-length thread.

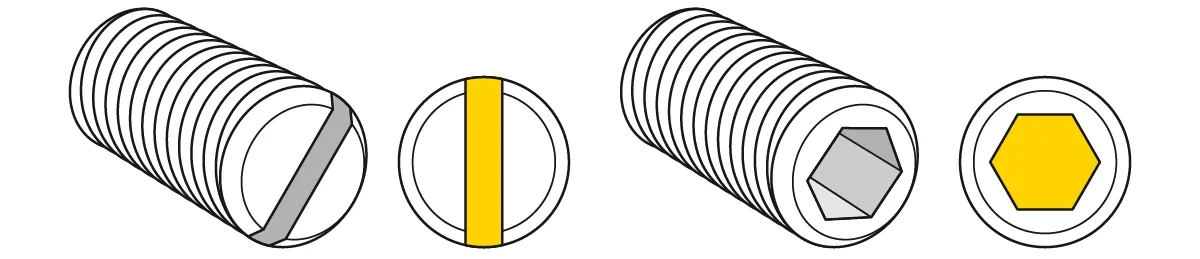

To be screwed in despite having no head, it features either a slot or — more commonly — an internal hex drive. Set screws come in various lengths, and the tip shape can vary depending on the intended use. They are available in different grades and materials, from brass to steel and stainless steel.

The thread of a set screw is typically nothing unusual. It usually has a standard metric thread in common thread sizes like M6, M8 or M10. Depending on the application, a metric fine thread may also be used.

Where Are Set Screws Used?

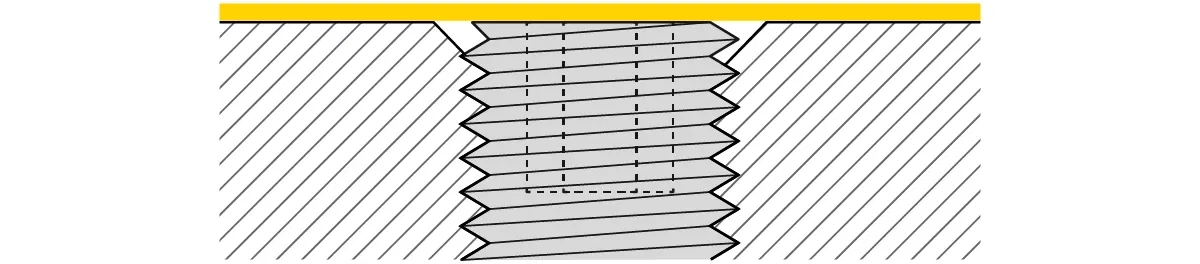

Since they don’t have a screw head, set screws can be completely recessed into a borehole. This creates a smooth finish with no protruding or visible elements. This is especially advantageous in technical equipment or machinery where components must function without obstruction or snagging.

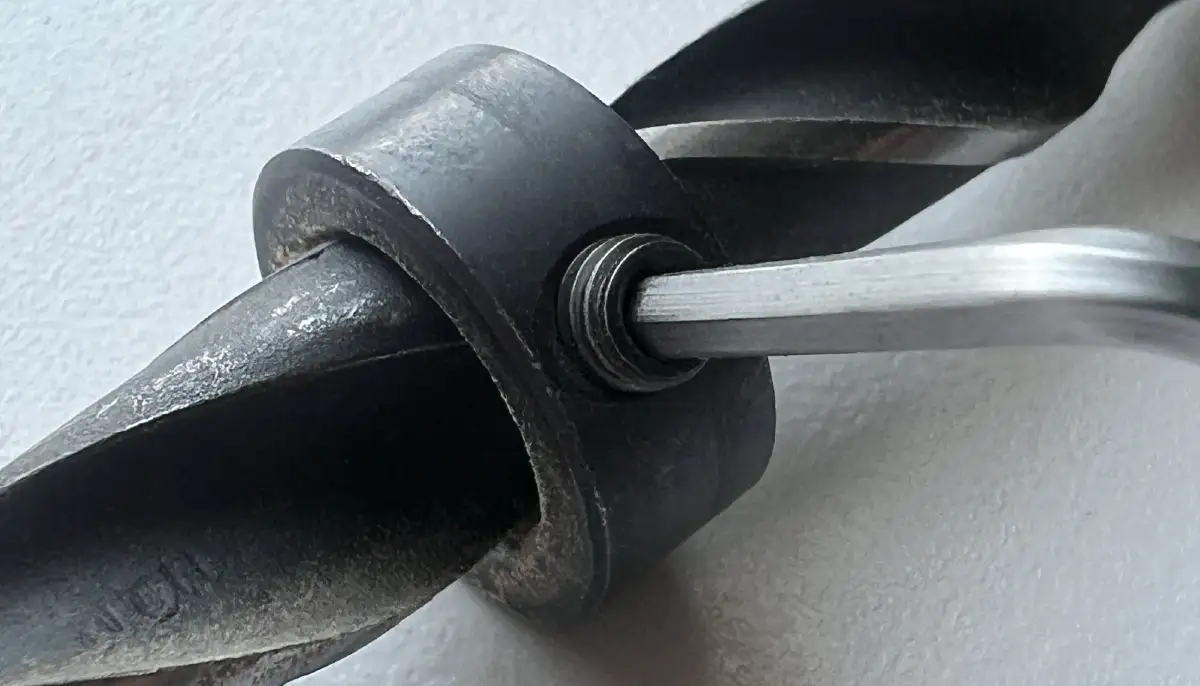

In most cases, set screws are used as set screws to secure the position of components, for example in collars, wheels, gears or other machine parts. They can be easily handled with common tools, making them highly flexible. They provide a firm hold yet can be quickly and easily released.

In precision engineering, set screws also serve as adjustment screws, allowing for fine tuning of measuring instruments, for example. In such cases, fine-threaded set screws are often used to enable micro-adjustments. Thanks to the smaller pitch, each turn of the screw moves it less than a standard thread would. This allows for extremely high precision.

Types of Set Screws

Aside from length and material choice, set screws mainly differ in the design of the front end. This determines how the intended fixation is achieved. A balance must always be struck between providing a strong hold and avoiding damage to the component.

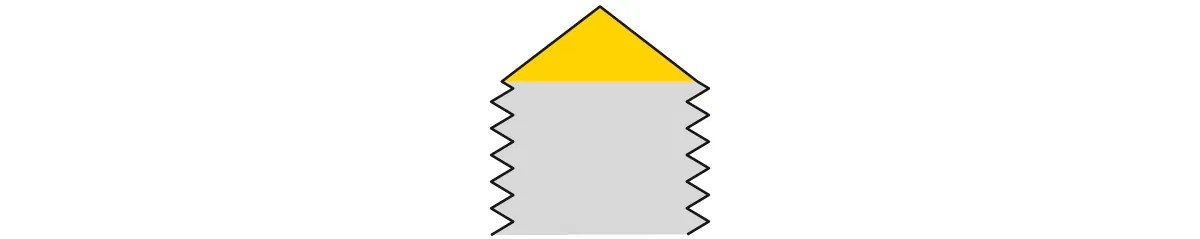

Set Screws with Cone Point

This type of set screw features a simple cone point that secures the component via clamping force. The hold is not as strong as with other variants, but the material of the counterpart remains undamaged, and the set screw can be removed without leaving lasting marks. This type is also well suited for flat surfaces.

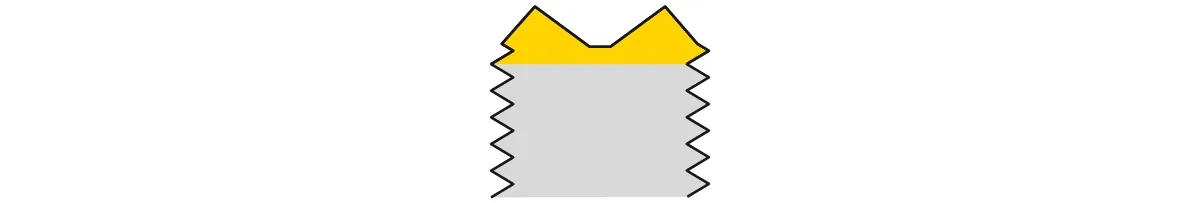

Set Screws with Point

A pointed set screw ensures a secure hold by digging its tip into the material of the mating part, thereby locking it firmly in place. Depending on the material, a groove or recess can be pre-machined to receive the tip. This variant is not suitable for delicate components that must not be damaged during locking.

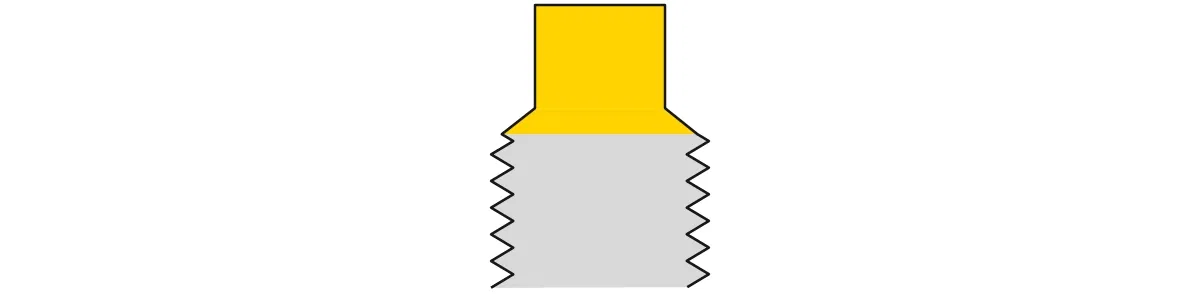

Set Screws with Dog Point

A set screw with dog point only functions if it engages with a pre-drilled hole. It is commonly used in through-holes. The dog point itself can take various shapes — cylindrical, as a pressure stud, or as a ball-shaped pressure point that can also serve for clamping when matched with the right counterpart. Soft plastic tips are used to prevent damage or pressure marks on sensitive components.

Set Screws with Cutting Ring

A set screw with cutting ring forms its own seat the first time it’s screwed in. The front end is equipped with a cutting edge. This design offers a particularly strong hold but causes irreversible damage to the component.

Whether you’re using set screws or conventional screws — you’ll find the right tools for thread processing in the BAER Online Shop. Rely on our expertise and decades of experience in manufacturing thread-cutting tools and accessories. Top quality and unbeatable delivery times are standard for us. See for yourself. We look forward to serving you.