Sustainable Tool Manufacturing: Trends and Future Visions

The latest developments and trends around the topic of sustainability have long since reached the tool industry as well. At BAER, it is our commitment to stay on the ball and approach new challenges with curiosity and optimism. That’s why, as a company, we are happy to take on the task of optimizing the sustainability of our products by developing new technologies and adapting production processes.

Environmental friendliness, especially in the field of machining, can be viewed from many different angles. It can be improved both before and after the end of production and presents a variety of challenges that we try to meet with innovative solutions. In this blog post, we want to explore which adjustment screws we can turn to better combine efficiency and profitability with good environmental compatibility—without compromising on quality.

Resource-Conserving Tool Production

In production, a significant contribution to greater sustainability can already be made—while also posing the greatest challenges. Not everything that would be best for the environment can realistically be implemented. Here, innovative spirit and creative solutions are especially crucial.

Energy Consumption

Energy consumption is one of the most obvious factors for increasing environmental compatibility in the production process. This starts with the sourcing of the required electricity, where ecologically sound alternatives can make a big difference.

But saving energy is also a great way to produce more sustainably. Proactive maintenance processes and smooth quality control during ongoing operations prevent production downtime and unnecessary steps. This ensures that only the energy that is truly needed is used.

Coolant and Lubrication Systems

There is great potential for reducing environmental impact in both the selection of the coolant and lubricant used and in establishing a filtration system. The more cooling cycles the fluid can go through before disposal, the greater the effect on environmental protection. Well-tolerated substances further reduce risks to people and nature.

Eco-Friendly Materials and Processes

Especially in the field of machining, the choice of base materials for tools is limited. However, it is possible to control where the raw material is produced. This allows for short delivery routes, which positively impacts CO₂ emissions.

Optimizing the processes used in tool manufacturing should also aim to save resources. Avoiding waste and rejects remains one of the most accessible ways to enhance environmental protection.

Smart Tool Design Supports Sustainability

A completely different approach focuses on the design of the manufactured tools. Here too, the savings potential in terms of energy consumption and resources is immense.

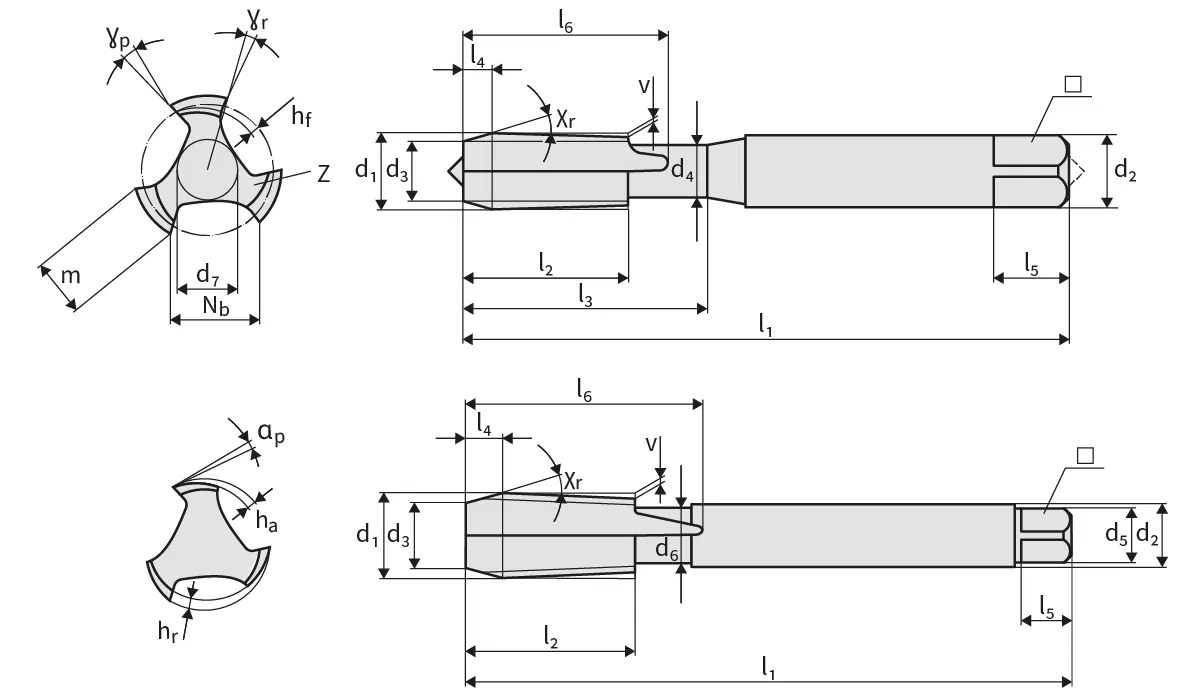

Thread cutting is an energy-intensive process. Precision tools designed to reduce the required cutting forces while maintaining the same productivity make a significant contribution to the industry's sustainability.

In concrete terms, this means that through optimized geometries and innovative coatings, the energy required for machining can be reduced. This is a great opportunity for sustainable environmental protection that has a lasting impact even after the products are sold.

Recycling and Reusing Cutting Tools

But it’s not just the industry—individuals at home can also contribute to greater sustainability and protect the environment. After all, nothing saves resources as reliably as refraining from making new purchases.

Of course, this doesn’t mean you should keep using tools that have become unusable due to wear. But we have some ideas on how to postpone a new purchase for as long as possible without compromising the quality of your work results.

Long Tool Life Reduces Waste

Long tool life is no accident. From the start, you can take steps to ensure your tools last as long as possible. The first step is purchasing a high-quality tap suited to your specific application.

Inferior steel as a base and using the same tap for every project? That won't work for long. Buying high-quality precision tools protects the environment—and, in the long run, your wallet too. So don’t be put off by a higher purchase price—over time, repeatedly replacing broken taps will cost you more.

Regrinding Instead of Disposing

No matter how high-quality your tap is, wear is inevitable. Even if you do everything right, your tool's lifespan is ultimately limited. But that doesn’t mean you can’t extend it.

Even a worn tap doesn’t necessarily have to be scrapped if it can be reground. Professionals can restore the tap’s original condition so you can keep using it. Our BAER regrinding service is happy to take care of your discarded tools.

Careful Handling for Long Service Life

To minimize wear and prevent damage or even breakage of a tap, a few precautions are also advisable. Always ensure that the tool you’re using is actually suited to the project you have in mind.

Threads in blind holes in particular are prone to issues and should be approached with care. Additionally, ensure adequate lubrication for each use—one of the most effective ways to reduce tap wear.

Also, consider storage and transport when trying to minimize wear. Store taps individually, in a dry and clean place, to enjoy them as long as possible. This benefits both the environment and your wallet.

At BAER, the passion for innovation is an integral part of our company culture. Together with partners from various industries and in constant exchange with our customers, we are always working to improve—especially when it comes to sustainability. You can see the results of our efforts in our online shop. Take a look and see for yourself!