The Leadscrew - Motion Thread with Unique Properties

A thread is a simple mechanism that always works in a similar way, or so you might think. However, by specifically adjusting certain parameters, the properties of a thread can be changed with astonishing flexibility and optimized for a wide variety of applications. Steep threads are a wonderful example of this phenomenon.

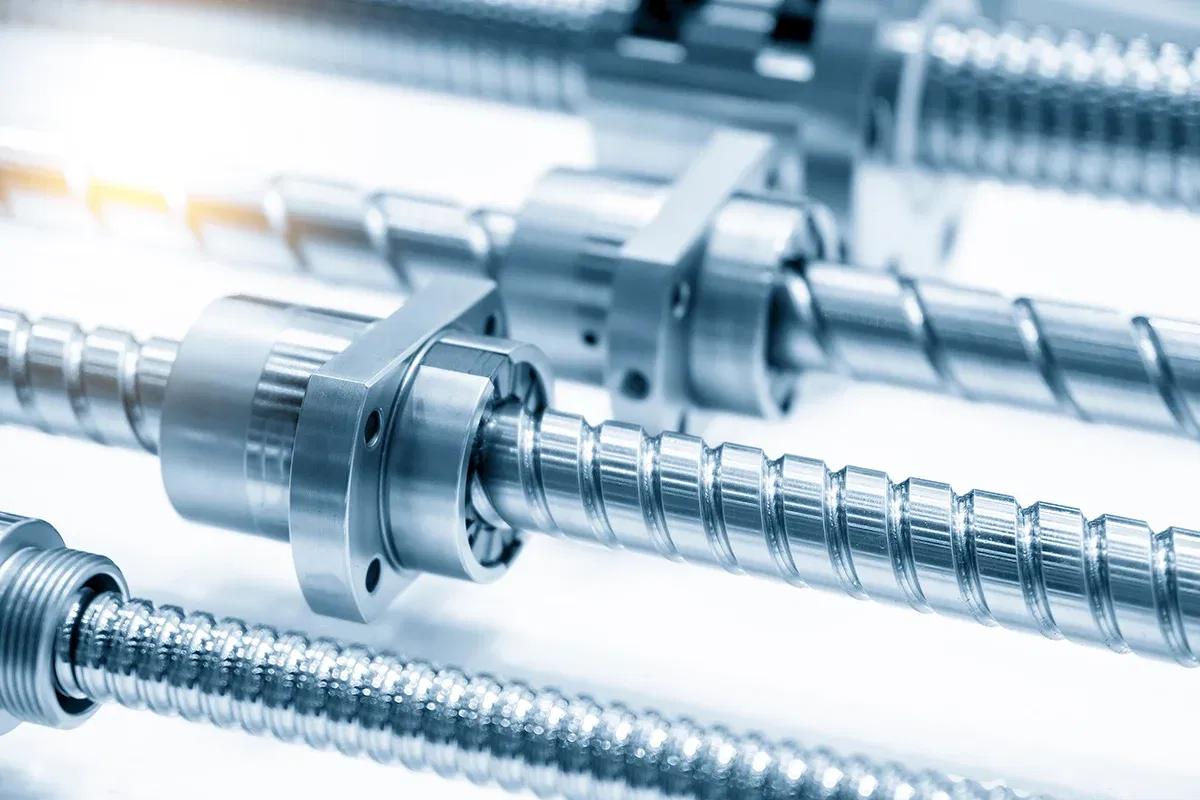

Depending on the design, the steep thread spindle cannot always be distinguished from other thread spindles at first glance. Nevertheless, it has a feature that makes it unique and gives it amazing properties. It sounds like magic, but as always, it's just physics. Want to know what it's all about? Then read on and find out everything you need to know about steep threads!

How does a steep thread spindle work?

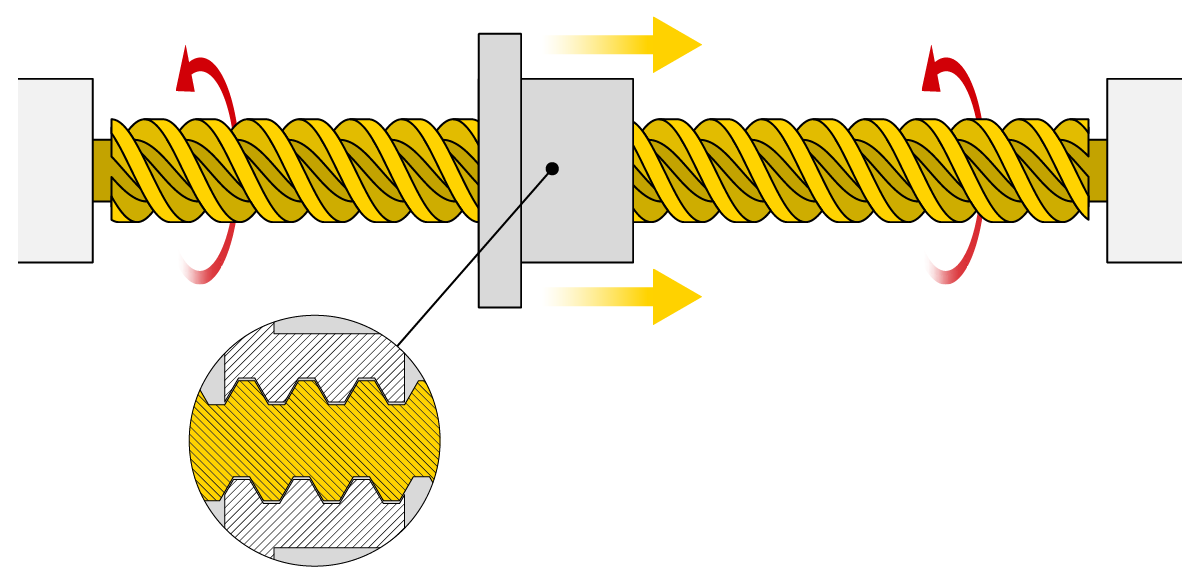

The steep thread is a motion thread and, as with other threads of this type, everything revolves around converting a radial movement into an axial movement. This means that when the threaded rod rotates, this leads to a movement along the axis. However, steep threaded spindles have a special trick up their sleeve.

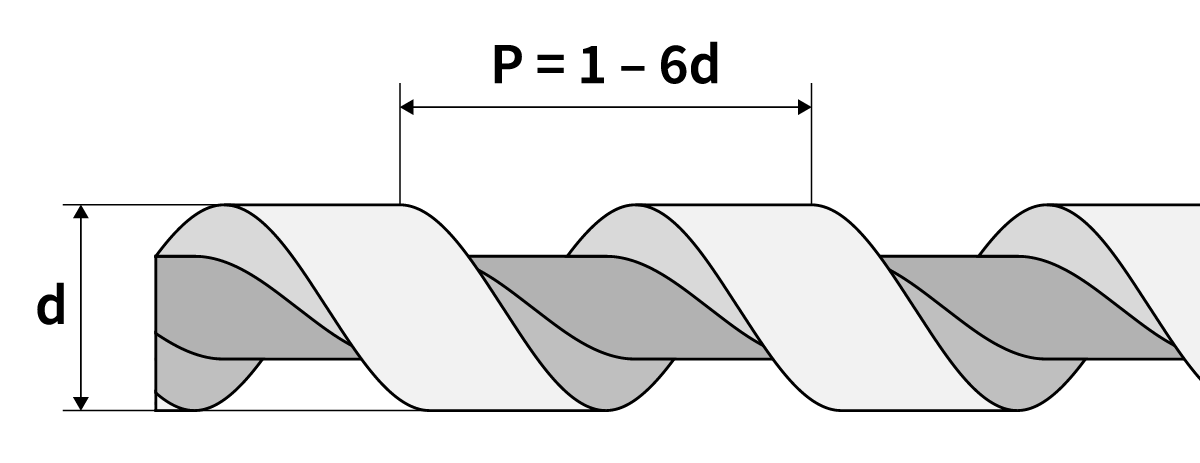

The pitch makes the steep thread unique

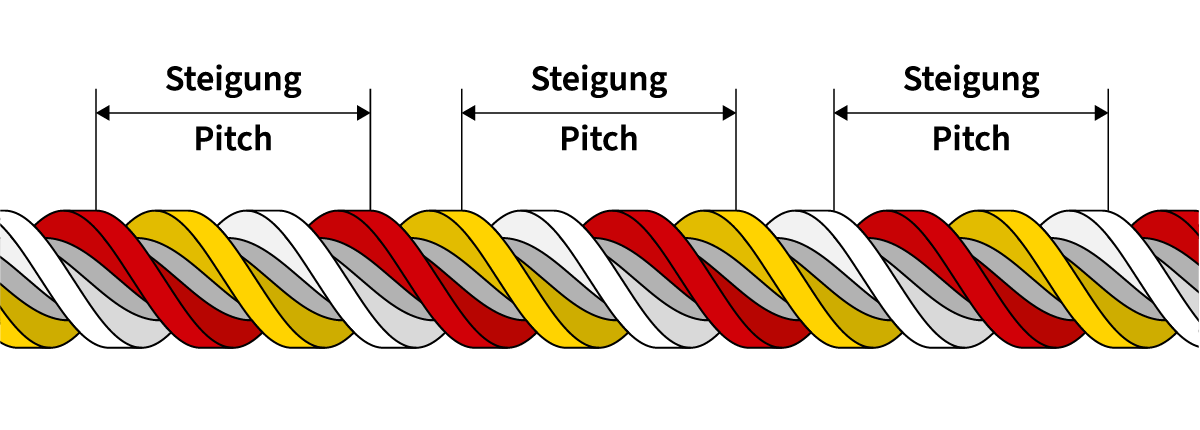

In fact, the main feature of the steep thread is a very high thread pitch. This variable is the distance between two thread tips of the same thread. Threads are generally referred to as steep threads if their pitch is at least equal to the diameter, but there are also examples with much higher values - sometimes up to six times the diameter!

There are two ways to achieve such a large thread pitch:

Wide thread profile

Firstly, you can simply widen the thread profile. You can easily recognize such steep threaded spindles by their very characteristic appearance, which is characterized by wide thread valleys and wide and flat “thread peaks”. The disadvantage of this method is that there is less contact surface between the screw and nut to bear the load acting on the threads.

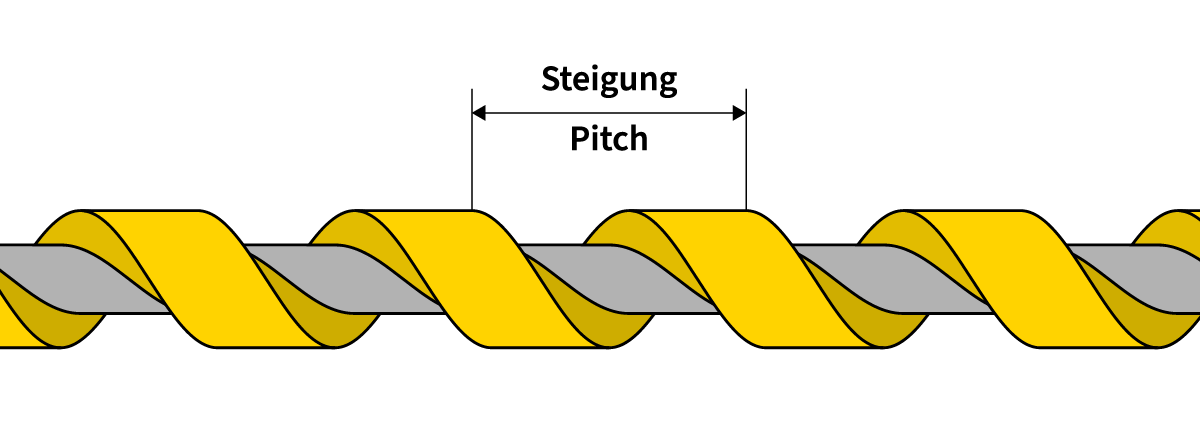

Multi-start threads

This problem can be solved with multi-start threads. There is no longer just one thread winding around the spindle, but two or even more. In this way, the load is better distributed. On the other hand, more contact surface also means more friction and heat during operation.

Caution: With multi-start threads, you must always keep an eye on the terminology, as adjacent thread tips no longer belong to the same thread. The correct term for this distance is now division. The pitch is still to be looked for between the thread tips of the same thread, even if it is no longer easy to tell which two are which.

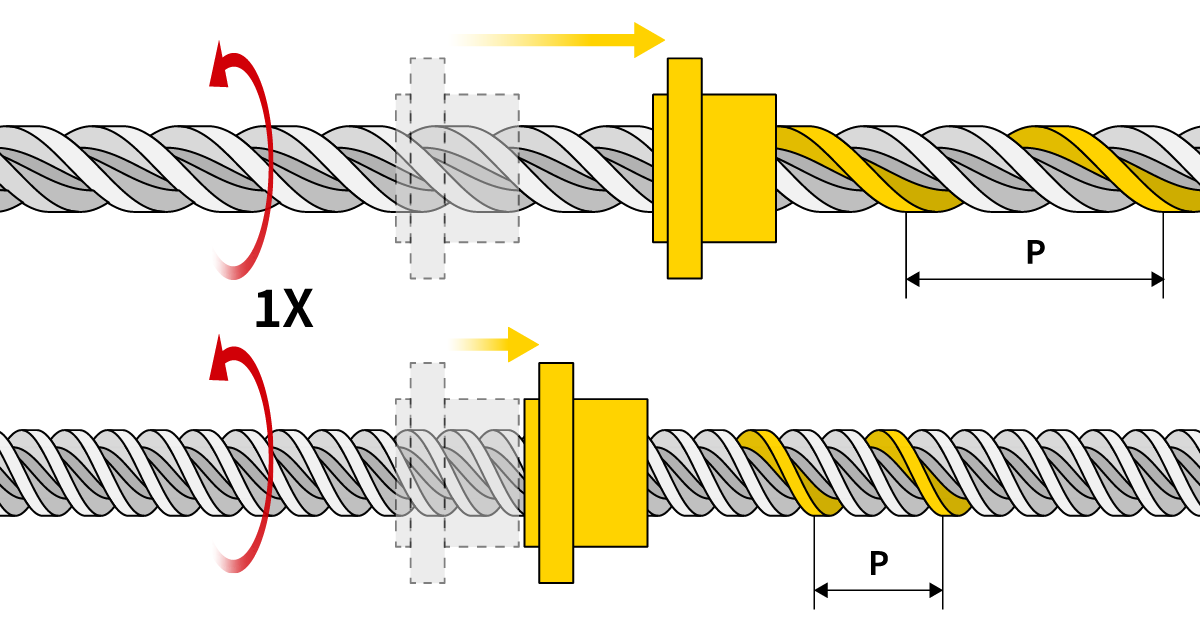

How the thread pitch affects travel speeds

We have now clarified how the large thread pitch comes about, but what does it actually do? The value always also defines the distance that is covered per complete revolution - so with a very high pitch, this distance is also very large. Or to put it another way: With a lead screw, a small radial movement can be converted into a large axial movement. High travel speeds are therefore also possible at low speeds.

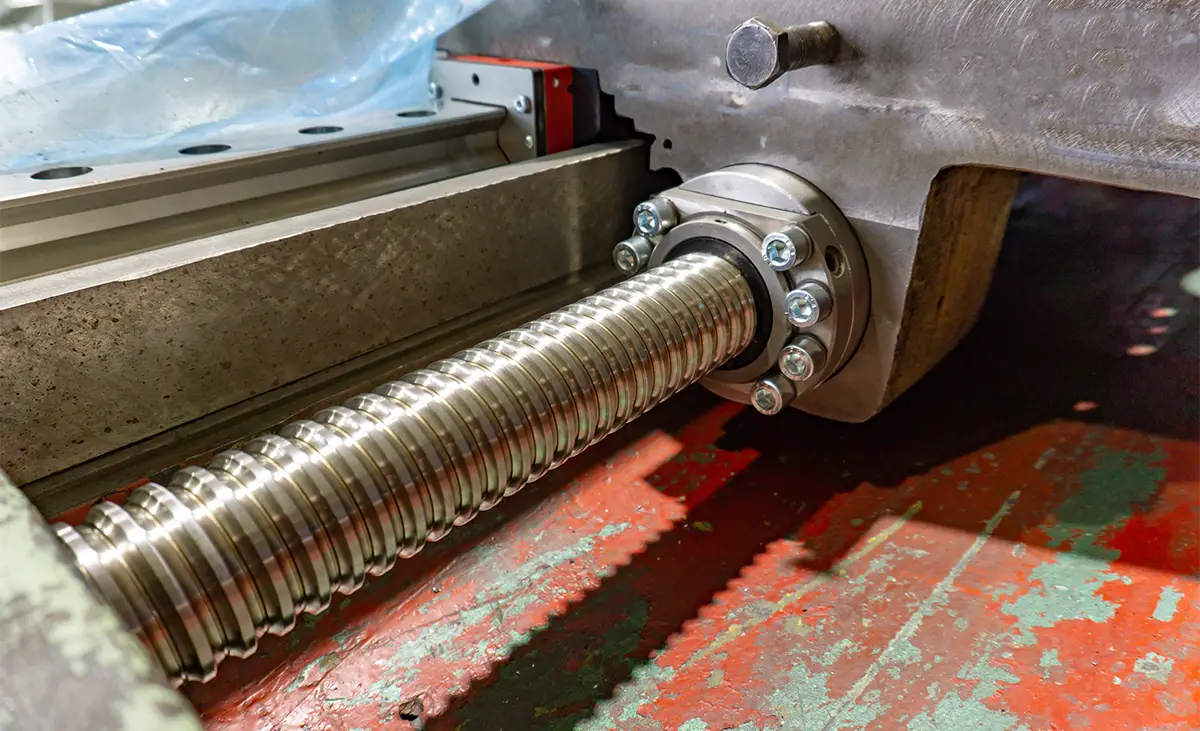

Multi-talented in industry and technology: this is where lead screws are used

The lead screw is used as a drive solution in numerous areas. They drive locking systems or ensure that doors, gates and windows open automatically. They can be found in printing and packaging machines as well as in swivel motors and rotary drives. And it is also impossible to imagine robotics and medical technology without the steep thread.

How the steep threaded spindle differs from another threaded spindle

In addition to the steep thread, there are other thread types such as the trapezoidal or round thread, which are often found on threaded spindles. What are the differences between these variants and how are they used?

Self-locking with the steep thread

Self-locking is an important factor that always plays a role, especially in motion threads. It describes how much force is required to overcome the resistance created by the friction between the bolt and nut. Put simply, it is about how easily a nut can be moved on a bolt or - in the case of fastening threads - how easily a bolt can be loosened.

How large or small the self-locking force should be always depends on the area of application. In many cases, a high self-locking force is advantageous because it means that a screw lock or an external brake is not required. Low self-locking, on the other hand, is associated with higher efficiency and a lower requirement for lubricants.

As self-locking always depends not only on factors such as the materials used or the lubricant used, but also on the angle of inclination, steep threads have very low to non-existent self-locking due to their large thread pitch. This distinguishes them from other spindles with a moving thread.

Easy to maintain and long service life

Thanks to the large thread pitch and low self-locking, these lead screws are not only particularly efficient, they also run very quietly and with low vibration. They are also characterized by high resistance to contamination and wear and, depending on the design, can even be operated without lubricant. Steep threads therefore offer good prospects for long, trouble-free operation and low maintenance costs.

Are you looking for a specific product for thread machining? In our BAER online store you will find threading tools directly from the manufacturer. We are also happy to manufacture custom-made products for you based on your drawing or according to your requirements and desired specifications! If you have any questions or suggestions, please contact our customer service team. at any time.