The micrometer: perfect for those who take things very precisely

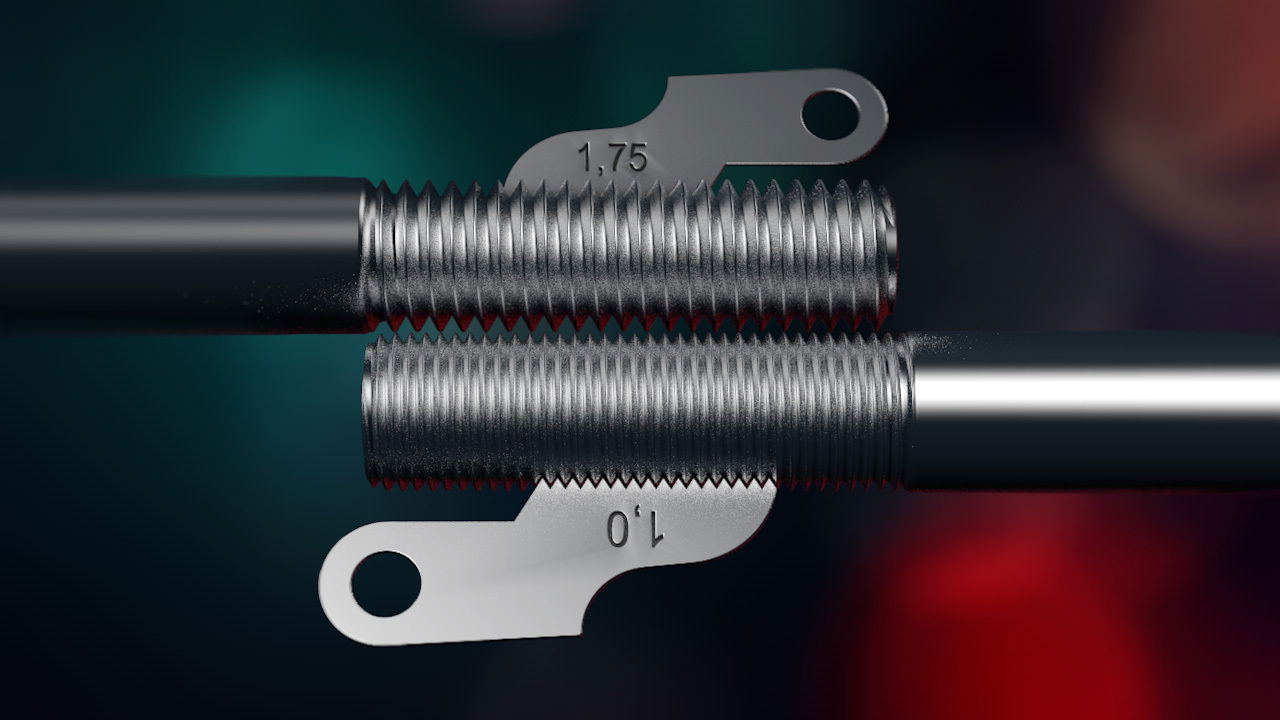

Fine thread or standard thread? You have probably already had to make this distinction in your manual work. The names alone give you an idea: the standard thread is generally regarded as the normal case, the fine pitch thread as a variant for special tasks. But for which tasks exactly? Of course, the fine pitch thread can also show its strengths as a fastening thread in certain areas. But with its small pitch, it is above all an expert wherever fine adjustments need to be made.

Measuring screws, also known as micrometers or micrometer screws, are a good example of this application. These measuring devices are characterized by extremely accurate measurement results, and this is precisely why they require a fine thread. Read on to find out how this is connected and how to measure with maximum precision.

Success thanks to a fine thread: how the micrometer works

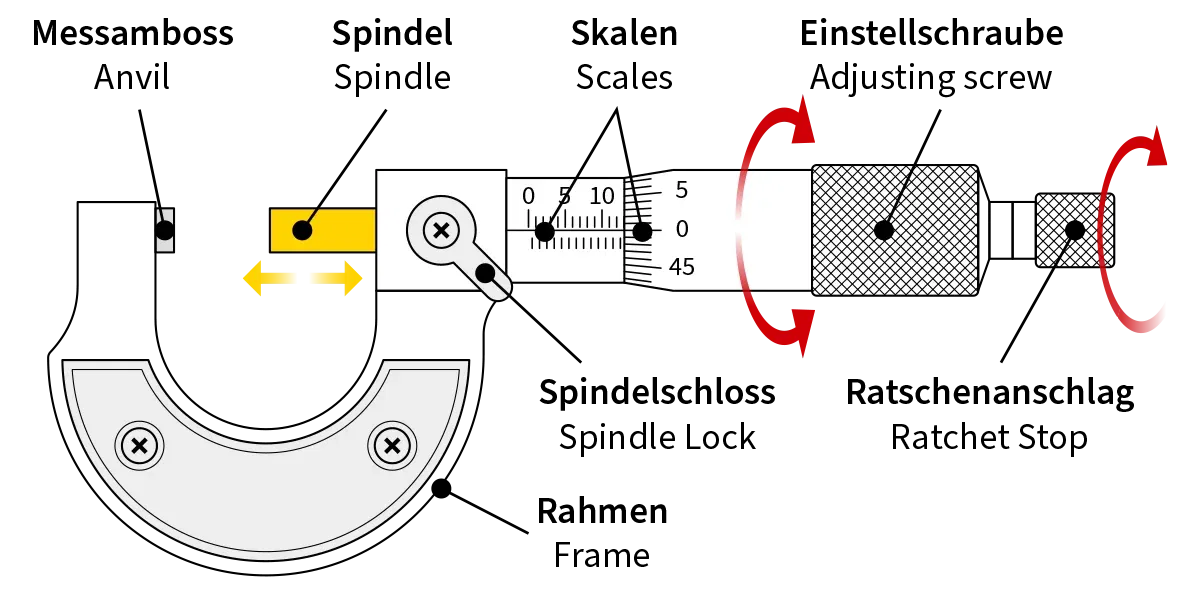

Let's take a closer look at measuring using micrometers by first familiarizing ourselves with the structure of the device. We will then see how to use it correctly. This is particularly important in this extremely fine measuring range. This is the only way to ensure that you obtain reliable measured values.

Structure of a micrometer

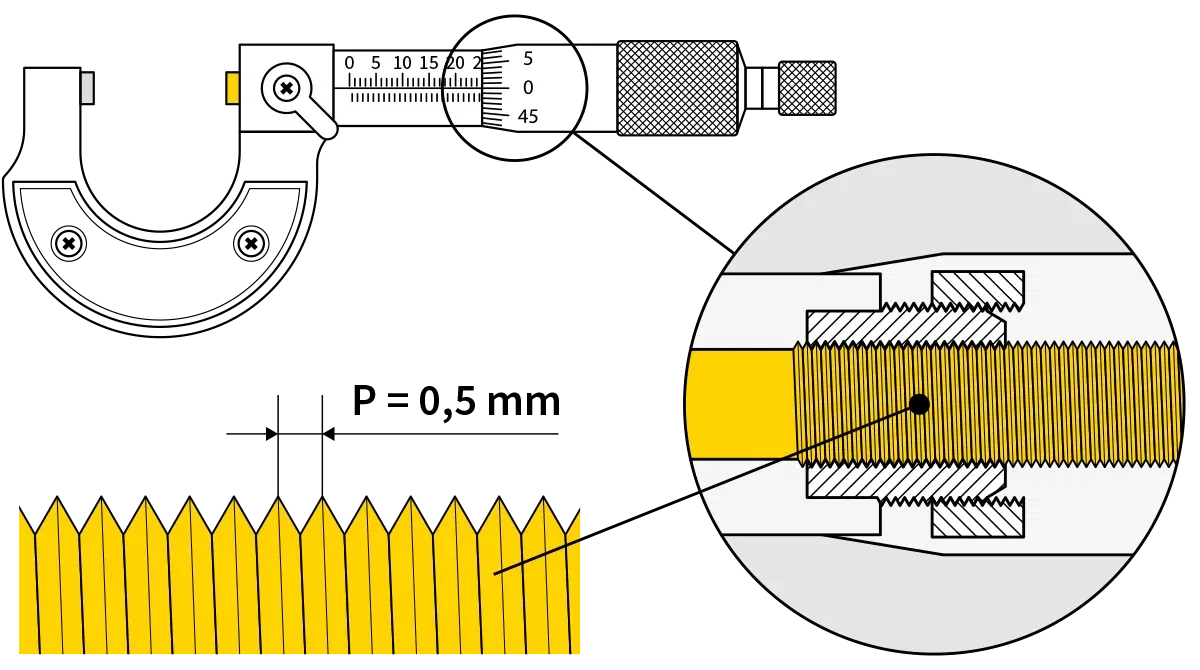

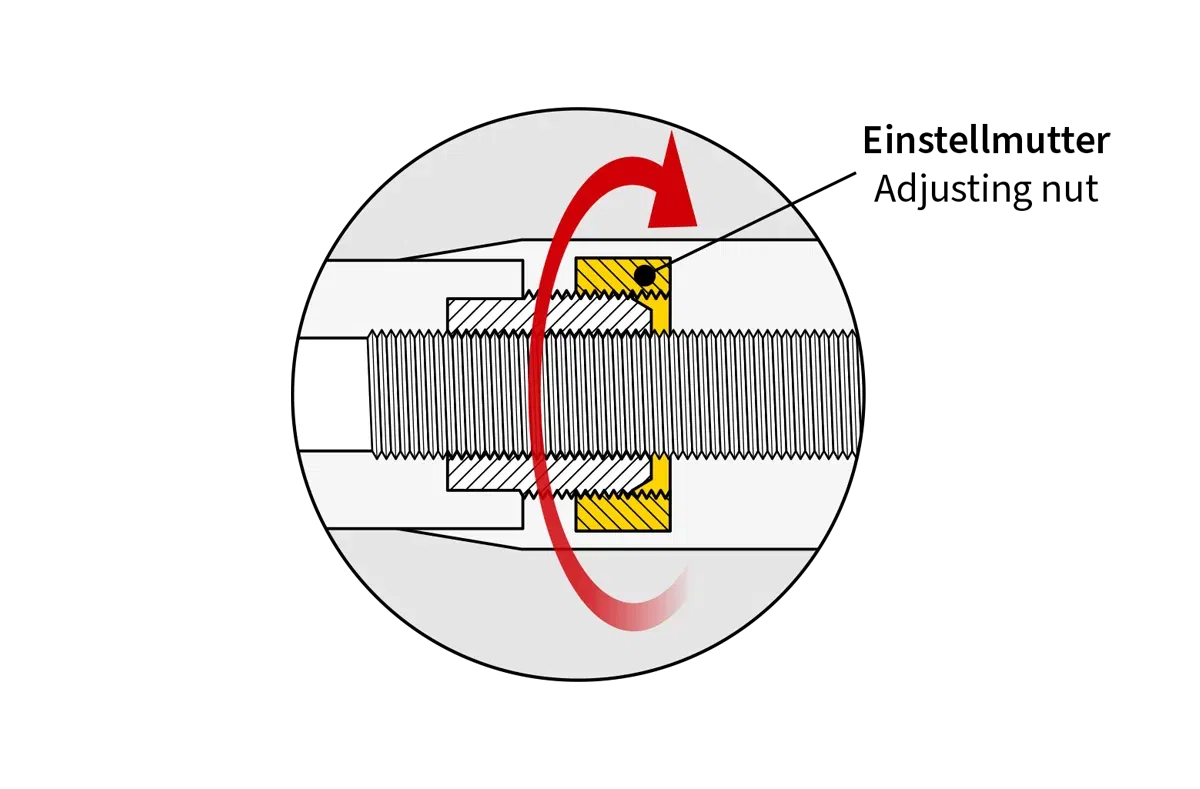

The principle of micrometers is based on two measuring surfaces. The measuring anvil is rigid, while the measuring spindle can be moved. The spindle can be opened and closed using an adjusting screw - this is where we find the fine thread. Due to the small pitch, the measuring surface moves less than one mm per revolution.

Two different scales attached to the micrometer are used to read the values determined. The zero point and the clearance can also be set.

How to use the micrometer correctly

The greater the accuracy of the measurements, the greater the need for correct execution, as the measurement result can otherwise be falsified. Fine threads are no longer of any help. So, what is the right way?

It is important that the general conditions are right. The device and test specimen should be at room temperature and the device itself should only be touched at the designated points, as the body heat emitted can be enough to falsify the result. The test specimen is then held between the measuring surfaces and the adjustment screw is operated until both surfaces have made contact. Micrometers have a clutch so that you do not apply too much measuring force here.

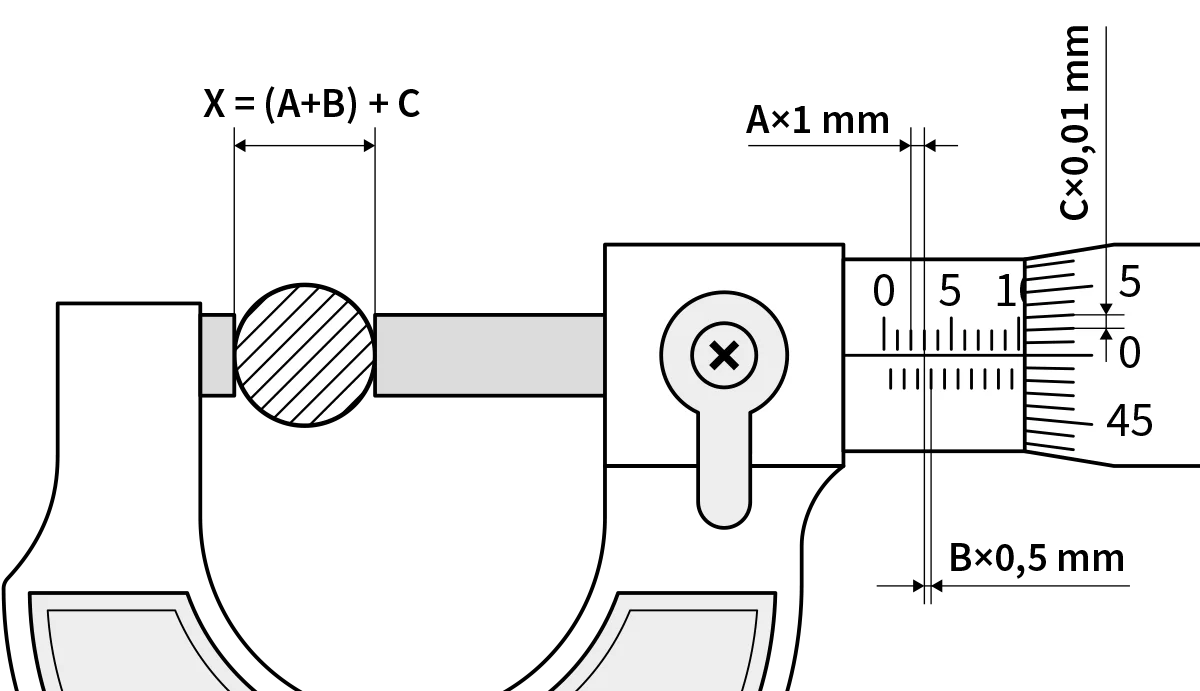

Now all you have to do is read the scales. There are two of these: one on the scale sleeve, which shows full and half mm, and one on the scale drum, where you can also read the finer 0.01 mm increments. You then have to add the two readings together, so a little arithmetic is required.

Working with two scales instead of one requires a little mental flexibility at first, but give it a try and you will see that there is a clear logic behind it all. If this is still too tedious for you, you can also use a digital device and simply read off the correct result.

By the way: micrometers offer the option of adjusting the play using an adjusting nut. Especially if you have been using the device for a long time, you should do this from time to time to guarantee long-term measuring accuracy.

These types of micrometers are available

Now that we have understood the basic operating principle, let's delve deeper. Because not all micrometers are created equal and some models have a few special tricks up their sleeve. Let's take a look at a few variants!

Outside micrometer

<the outside micrometer is so called because of the easily recognizable bracket that connects the two measuring surfaces. It is the most common version of this measuring device. Outside micrometers are suitable for measuring the outside diameter of a workpiece.

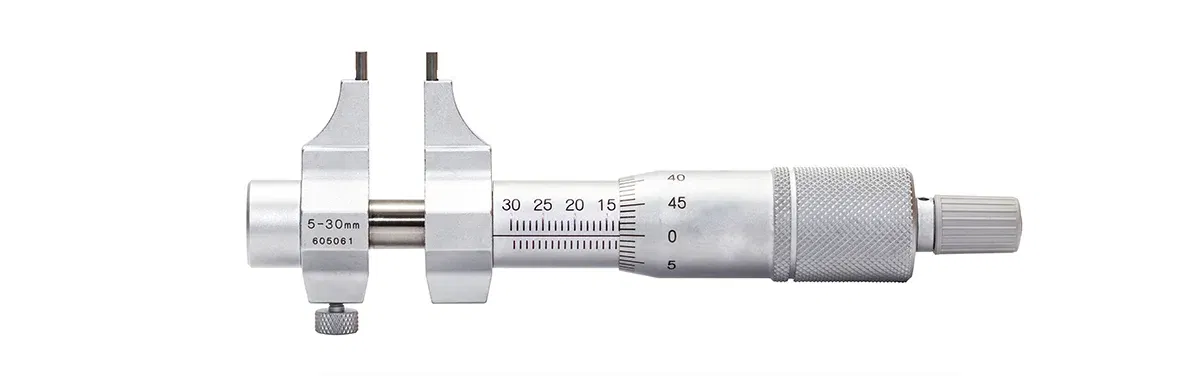

Inside micrometer

But what if you want to measure the inside diameter of a hole, for example? There are special micrometers for this, which are known as 2-point or 3-point micrometers depending on their design. The principle is the same, but in the opposite direction: instead of moving from the outside towards the outer surfaces, the measuring surfaces move from the inside towards the inner surfaces.

Further variants of the micrometer

A micrometer can be adapted very precisely to specific areas of application by changing the shape and size of the measuring surfaces. In this way, a very specific measurement is possible. For example, there are micrometers that are used to measure a thread and can determine the pitch diameter instead of the outside diameter. Spherical measuring surfaces help to determine the wall thickness of a pipe.

The micrometer head screw is also a special form. This is permanently mounted and makes it possible to move components in a targeted manner or, conversely, to ensure that a movement does not exceed the desired dimension.

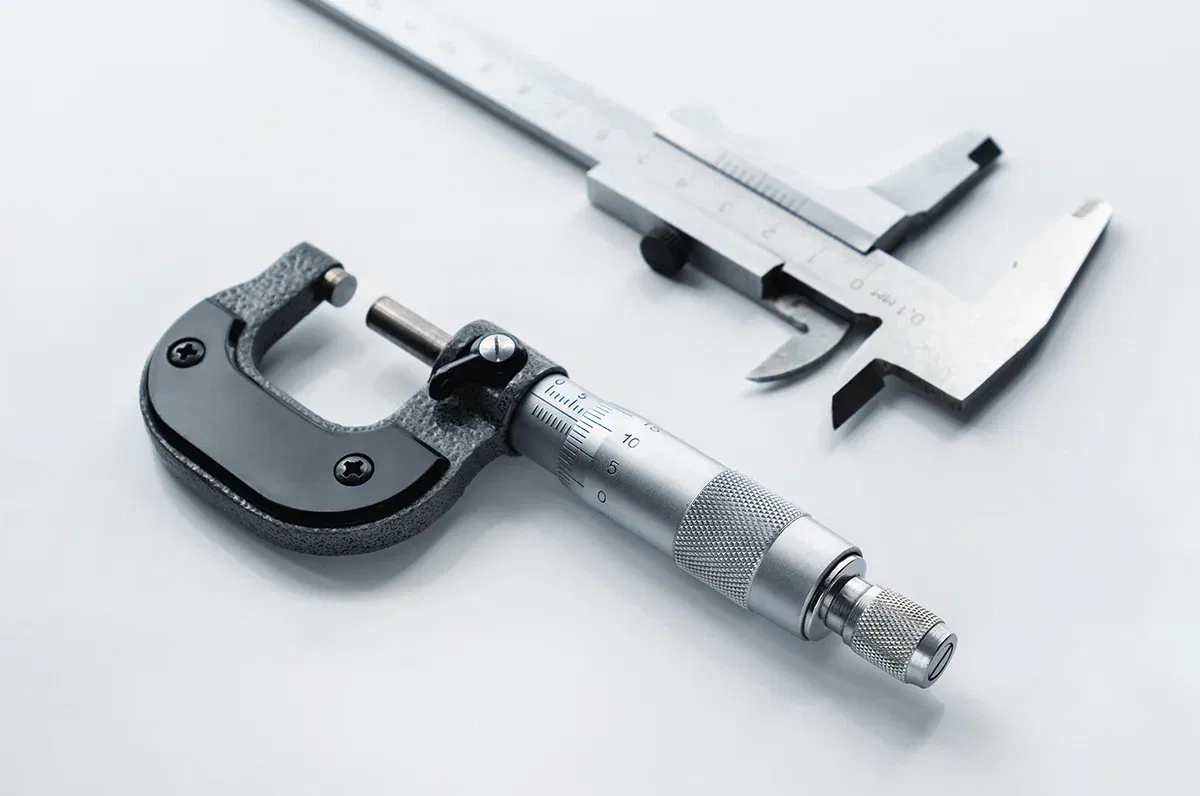

Micrometer or caliper - what's the difference?

Does the principle of the micrometer remind you of a caliper gauge? In fact, these two measuring devices for lengths have a lot in common. However, the micrometer stands out due to its higher accuracy. Which of the two variants is more suitable for you therefore depends primarily on your measuring range and which has the highest priority for precision in your work.

A good caliper gauge achieves a measuring error of 0.01 to 0.02 mm. This should be completely sufficient for many applications. For more precise measurement results, you will need to use a micrometer, but in this case you should pay particular attention to error-free use. Otherwise you will quickly negate the advantages of the smaller caliper gauge.

You can also find everything about fine threads in the BAER online store! Plus many other tools for thread processing and lots of accessories. Take a look for yourself! If you have any questions or suggestions, our customer service team will be happy to hear from you.