These are the common threads for screw caps

Nuts and bolts are certainly the first example that comes to mind when you want to explain the concept of threads to someone. However, there is another area of application that you will probably encounter much more frequently in everyday life – threads for screw caps. Think about how often you open and close containers. From toothpaste tubes to thermos flasks and baby bottles, screw caps with threads are simply everywhere. And it's no wonder, because they are also incredibly practical. So practical, in fact, that they are now even becoming more and more popular for wine bottles and are about to overtake corks (even if true wine connoisseurs may protest at this point).

Why are threaded screw caps so suitable for sealing bottles, cans and tubes? How are they made and what types of threads are used? Let's take a closer look in this blog post.

What are the advantages of threaded screw caps?

The advantages of threaded screw caps quickly become clear when we consider what other closure systems are used for bottles, cans and tubes. We are familiar with crown caps from after-work beers, tear-off tabs from cola cans and tear-off lids from ready-made ravioli. What all these mechanisms have in common is the obligation to empty the container once it has been opened, as it cannot be closed again. The threaded screw cap, on the other hand, can be screwed back on at any time and then remains almost as tight as before it was first opened. And unlike a swing top, for example, the threaded screw cap is easy to produce.

How does the thread get into the screw cap?

When and how the thread is produced on the screw cap depends on the material. Plastic caps are usually produced directly with the appropriate thread. Metal caps, on the other hand, are often initially produced without a thread. The thread on the screw cap is then only created when the container is closed, when the threads are pressed into the material. Depending on the area of application, the cap is also provided with a suitable sealing insert.

These threads are used for screw caps

Screw caps with threads are available in many different sizes, with different requirements and made of different materials. The variety of thread types used for this purpose is correspondingly large. Below we present the most common thread types for screw caps.

Threads for plastic containers according to DIN 6063

The DIN 6063 standard for threads on screw caps for plastic containers consists of two parts, which differ in terms of the thread profile. The standard applies to bottles and cans that are designed according to the specifications of the DIN 55405 standard.

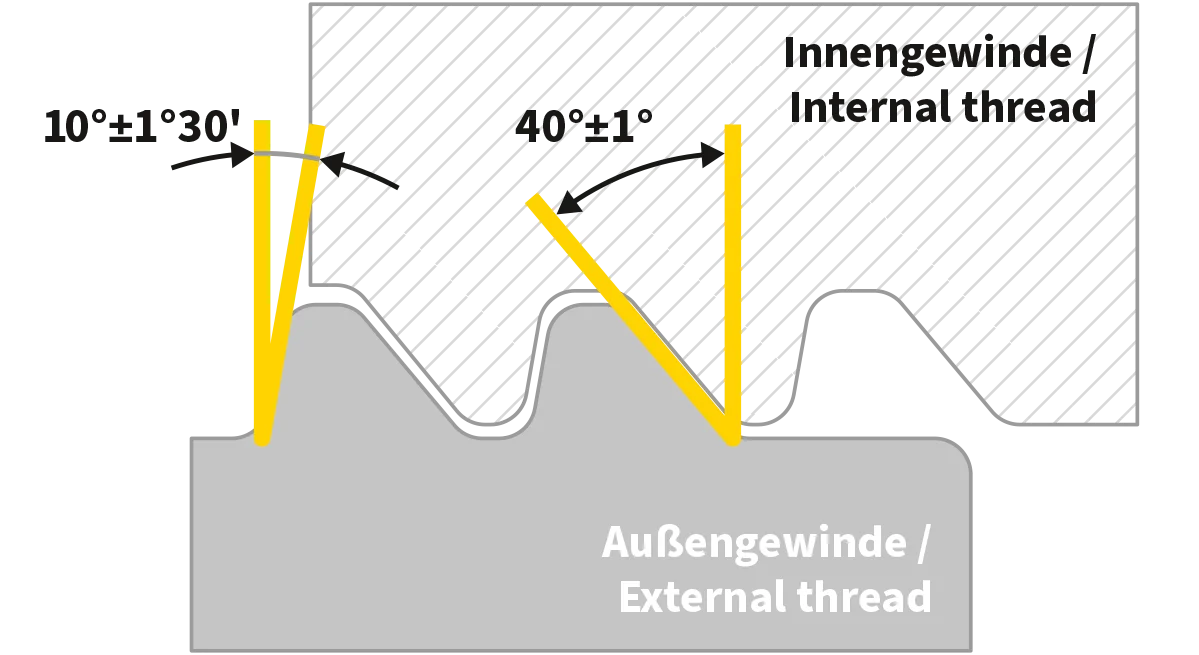

Saw thread for plastic containers according to DIN 6063-1

The thread for plastic containers in accordance with DIN 6063-1 is a saw thread. A saw thread is characterized by an asymmetrical profile that resembles the appearance of a saw tooth. On the load-bearing flank, the saw thread for plastic containers has a flank angle of 10° ± 1°30'. On the non-load-bearing flank, the flank angle is 40° ± 1° up to a nominal diameter of 22 mm, and 30° ± 1° for all sizes above this. The profile depth corresponds to half the pitch. The thread designation consists of the abbreviation KS for plastic saw thread and the nominal diameter in mm. The DIN 6063-1 standard specifies 18 sizes from KS 10 to KS 60, although some are bracketed and should be avoided if possible.

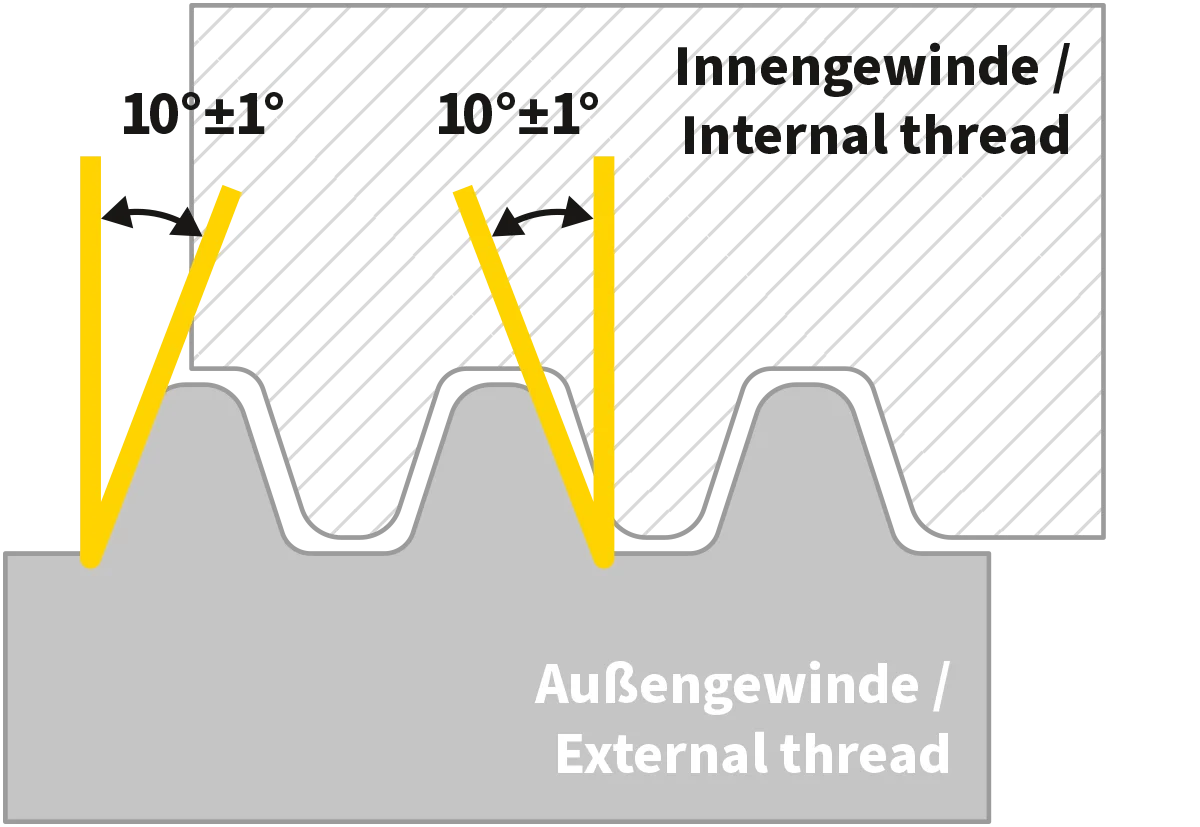

Trapezoidal threads for plastic containers according to DIN 6063-2

The second part of the DIN 6063 standard deals with the trapezoidal thread for plastic containers. The profile of this thread has the shape of an isosceles trapezoid. The flank angle is 10° ± 1° per thread flank and the profile depth corresponds to half the pitch. The thread is designated with the abbreviation KT for plastic trapezoidal thread and the nominal diameter in mm. According to DIN 6063-2, there are 17 sizes from KT 10 to KT 50, some of which are in brackets and should not be used if possible.

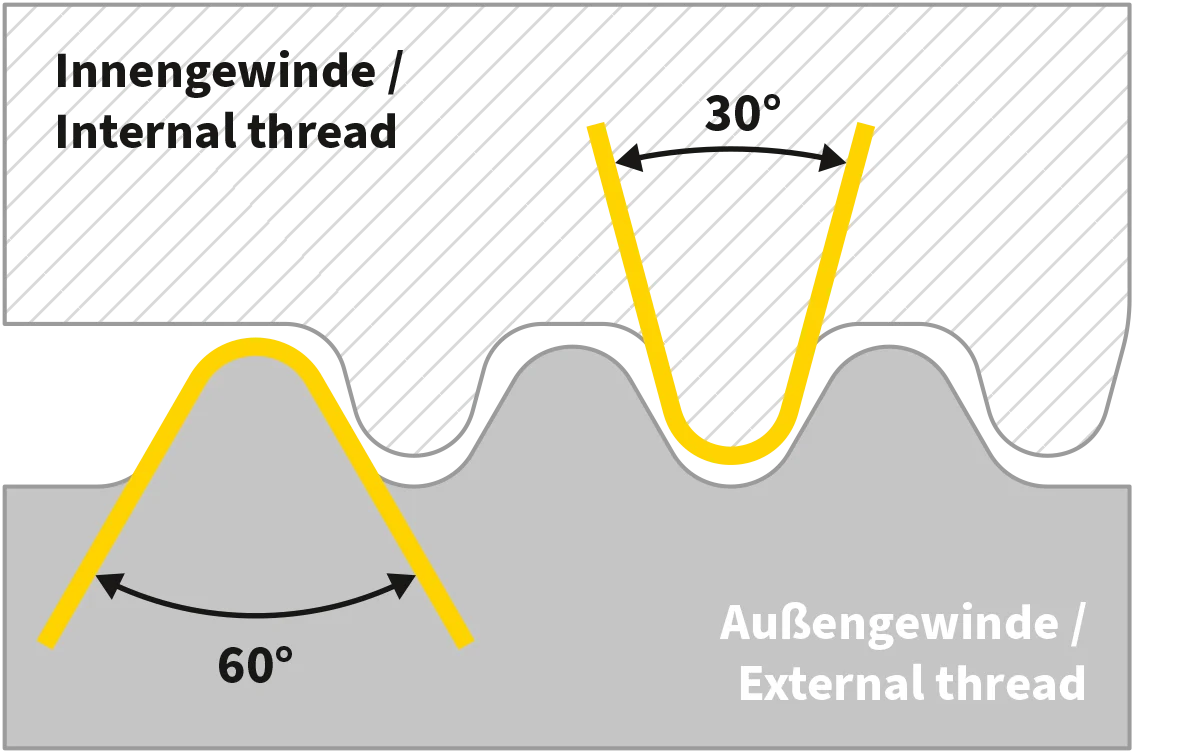

Round threads for glass containers according to DIN 168-1

The DIN 168-1 standard contains specifications for a round thread that is used for glass packaging. Round threads are characterized by the fact that they are resistant and easy to clean, which makes them particularly suitable for food packaging or laboratory containers. The special feature of the round thread according to DIN 168-1 is that the flank angle of the external thread is 60°, but only 30° for the internal thread. The thread designation consists of the abbreviation GL, the nominal diameter in mm and the pitch. A glass thread according to DIN 168-1 with a nominal diameter of 25 mm and a pitch of 3 mm is therefore correctly designated as GL 25 x 3.

Saw threads for plastic and glass containers according to DIN 55525

DIN 55525 specifies the dimensions for a saw thread that is used for plastic and glass containers with a standardized screw cap. The difference to the threads according to DIN 6063 lies in the fact that the thread profiles according to DIN 55525 can be used to close both glass and plastic containers with a plastic closure. However, the DIN 6063 standard stipulates that all components must be made of plastic.

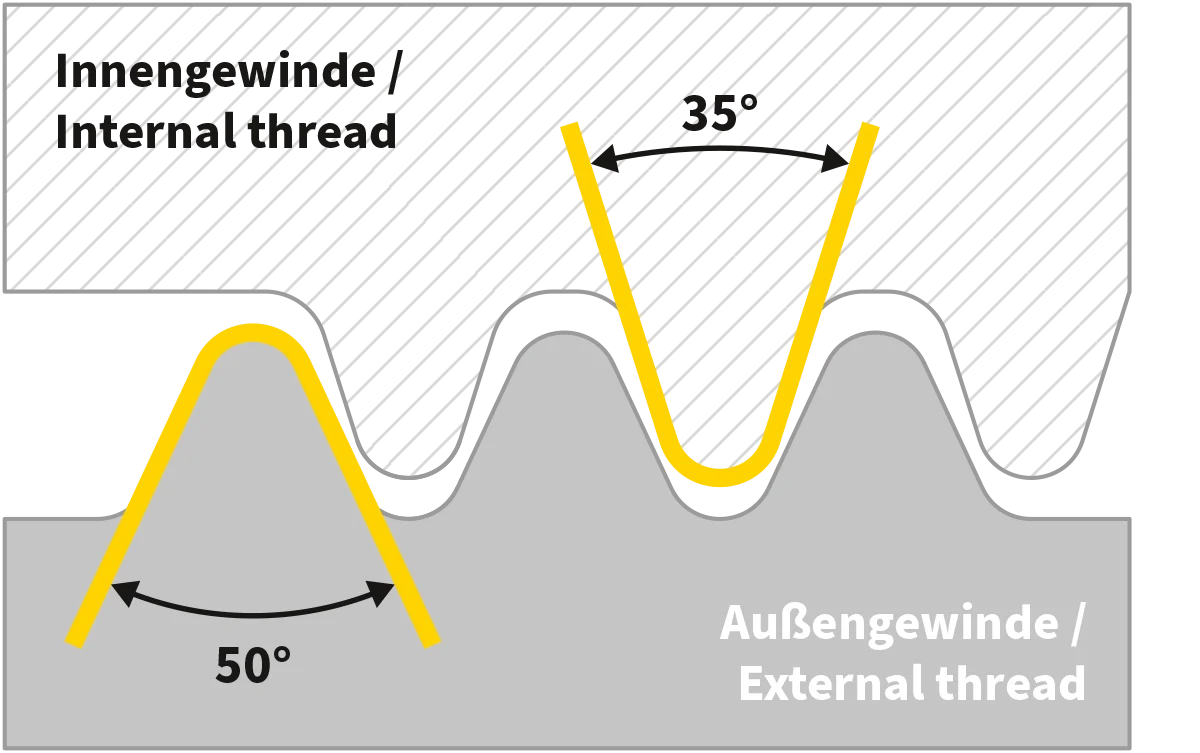

Glass thread according to DIN 40450

Although the DIN 40450 standard is already obsolete and has been deleted, some manufacturers still use this glass thread. The flank angle for the internal thread is 35°, that for the external thread is 50°. The glass thread according to DIN 40450 can be recognized by the abbreviation Glasg, but it should no longer be used if possible.

Are you looking for the right threading tool for your projects? In our BAER online store you will find taps and dies in all sizes and thread types as well as everything else you need. Just take a look around! And our customer service will take care of your questions and concerns.