Thread cutting – A beginner's guide

The thread cutting guide informs you about the most important methods and techniques related to thread cutting. Whether a professional or DIY enthusiast, thread cutting is one of the most vital elements of any craft. After all, the thread is the most common method to join two components together. No bolted connection would exist without it! However, not every craftsman dares to approach thread cutting so easily. Many perceive it as a particularly demanding task and instead opt for prefabricated components from the hardware store. Yet, manual thread cutting or using a machine requires only a little practice and a delicate touch, and it will also work in your home workshop.

Why not give it a try? In our thread cutting guide, we explain what to watch out for and provide an overview of the necessary steps. Soon, you'll be cutting your own precise threads like a pro.

Thread cutting tools - Explanation of key terms

When you first look for the right tool, you might be surprised by the many options at first. Before we delve into the thread cutting guide, some basic principles should be clarified.

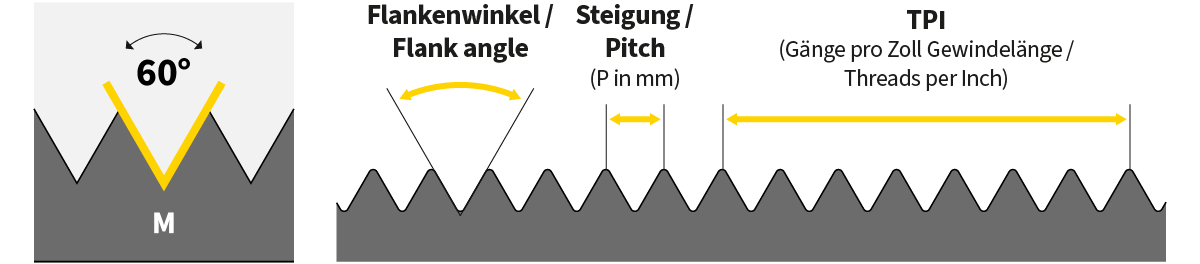

- Thread Standards: To ensure screws, nuts, and other components are interchangeable everywhere, there are standards that prescribe a thread profile. In Europe, you will most often encounter the metric standard thread, which is identified by the abbreviation M followed by a numeric value in mm indicating the outer diameter. So when buying your threading tools, make sure to select the correct standard.

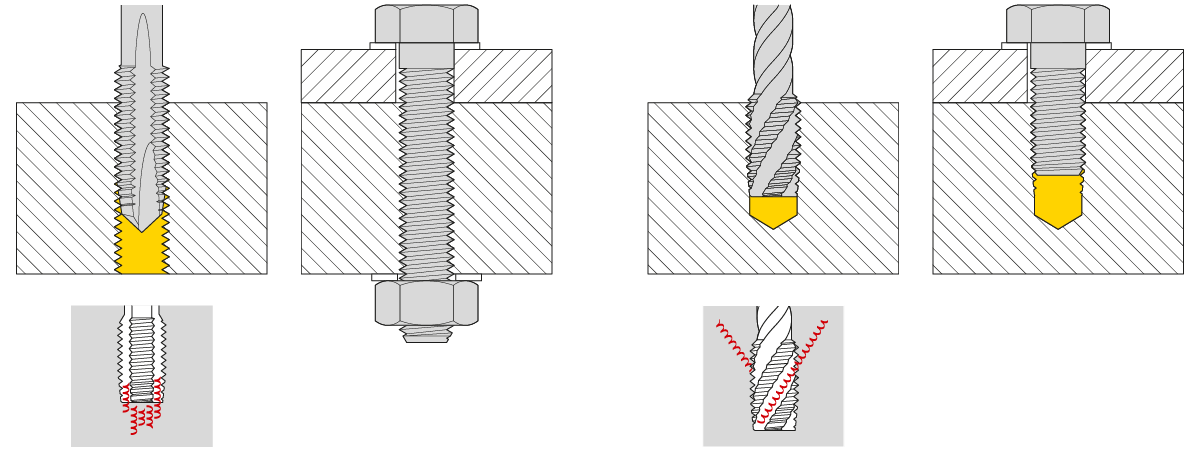

- Blind or through hole: For a through hole, you drill completely through the material, while for a blind hole, you only drill partway in. The distinction becomes important when it comes to chip removal. The blind hole tap automatically removes the chips through the spiral flutes. The through hole tap has straight flutes since removed material can exit at the open end of the hole.

- Left or right-hand thread: This concerns the direction in which a screw is tightened or loosened. Most threads are right-hand threads, but for some special cases, you may need a left-hand thread. You will also need the right tool for that – so pay close attention when purchasing!

Thread cutting by hand: The internal thread

In the first step of the thread cutting guide, it's about the method: Maybe you don't have the space or budget for large machines, or you just want to cut a thread on rare occasions. In that case, manual thread cutting is the way to go. With a hand tap set and a little finesse, even hobby DIY enthusiasts can succeed. The advantage is that you can work very slowly and with control. You'll immediately feel if your tool is under pressure, preventing damage.

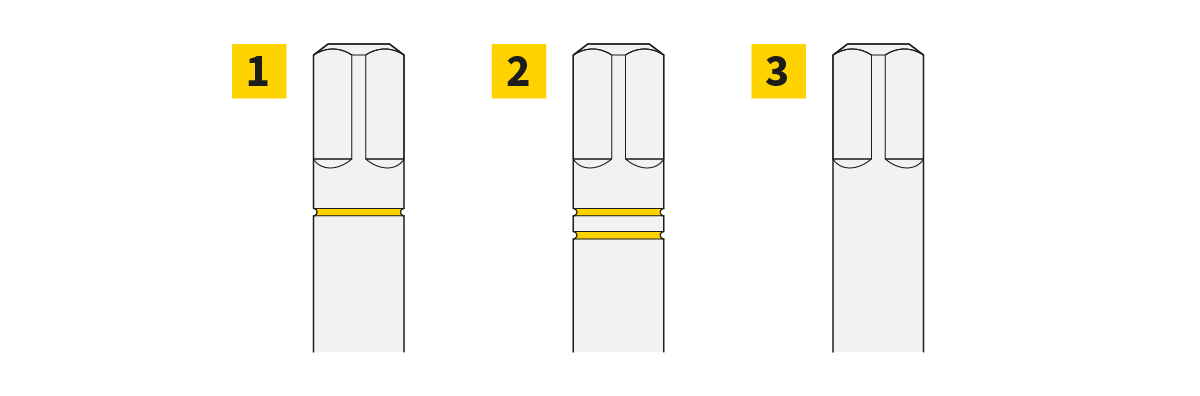

In the context of the thread cutting guide, keep in mind that thread cutting requires a lot of force. To make the process easier without a machine, manual thread cutting is divided into three steps. For this, you need special hand taps that come in sets of three tools: taper tap, intermediate tap, and finishing tap. The hand tap sets from BAER are a high-quality option.

Threading Guide – How it's done:

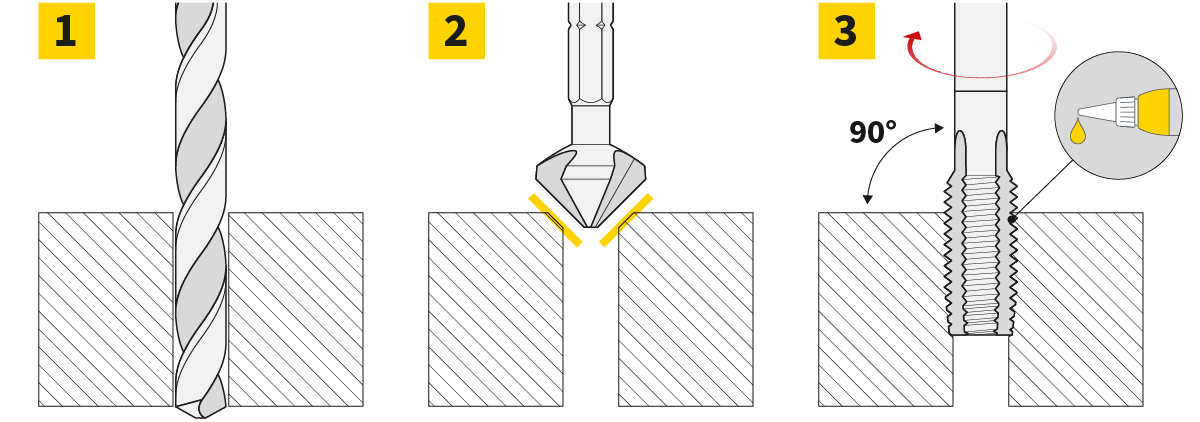

- 1. Pre-drill the core hole: Firstly, prepare the core hole using a regular twist drill bit. Calculate the appropriate size using a formula or refer to a chart. Such a chart can be found, for example, in the BAER Tools Online Shop linked in product descriptions.

- 2. Countersink the core hole: After drilling, sink the hole using a countersink. This makes aligning easier in the next step and ensures a clean finish.

- 3. Cut the thread: Apply lubricant to both the core hole and the screw tap, then begin the cutting process with the taper tap. Work slowly and carefully, always ensuring proper alignment. Repeat the step with the intermediate tap and then the finishing cutter.

Based on this threading guide, you'll be able to cut threads by hand without any issues.

Threading Guide: Cutting external threads by hand

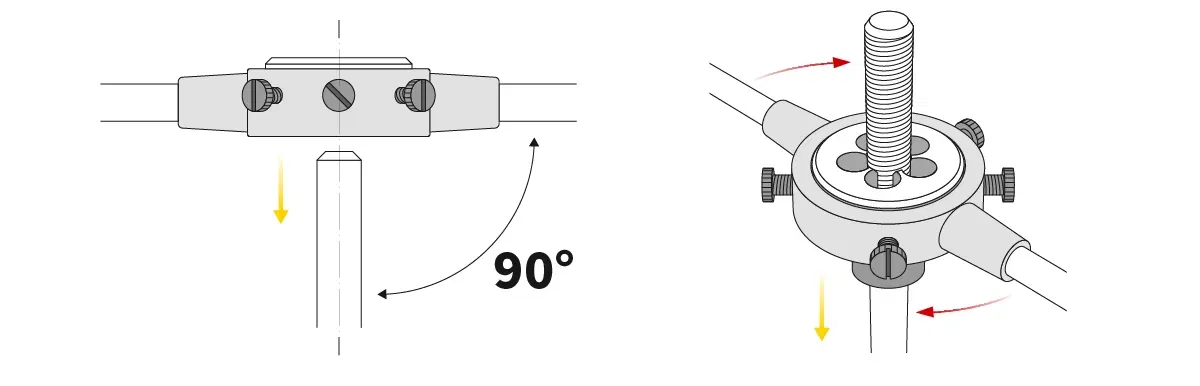

With the right threading guide, you can also cut external threads by hand: In addition to the suitable thread cutting die, you will need a die stock or holder. The thread cutting die is a cylindrical tool that internally consists of toothed stiles with several threads and chip evacuation holes, allowing the removed material to escape. On the outside, there's a V-groove and holes for the retaining screws, with which you fix the die in the die stock. Cut external threads in a single step by slowly turning it onto the workpiece. Pay particular attention to keeping it straight to avoid alignment errors.

Threading Guide – Demonstration of a thread cutting die:

For re-threading and especially hard-to-reach places, hexagonal die nuts can also be used with an open-end wrench.