Thread designations: Thread terminology from A to Z

When working with threads, terms keep cropping up whose meaning is not immediately obvious. We have collected the most important terms for you and explain what they mean.

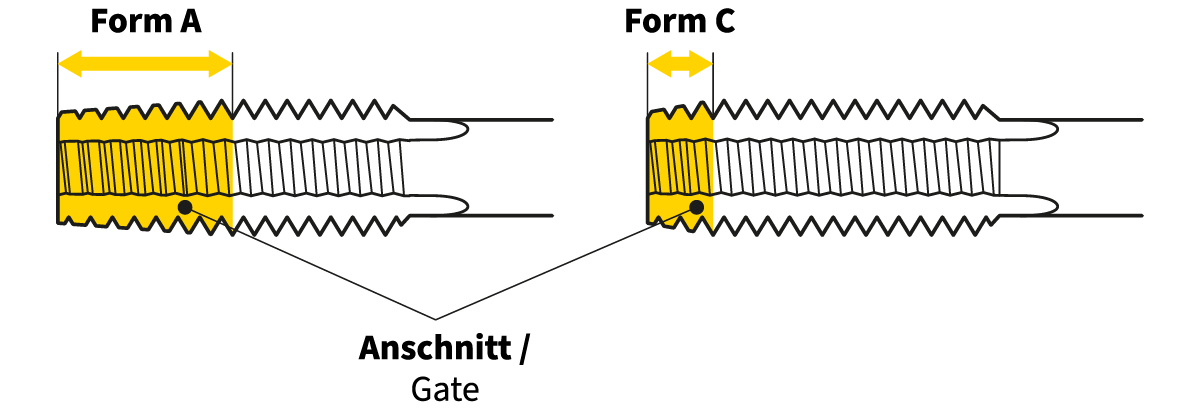

Bleed

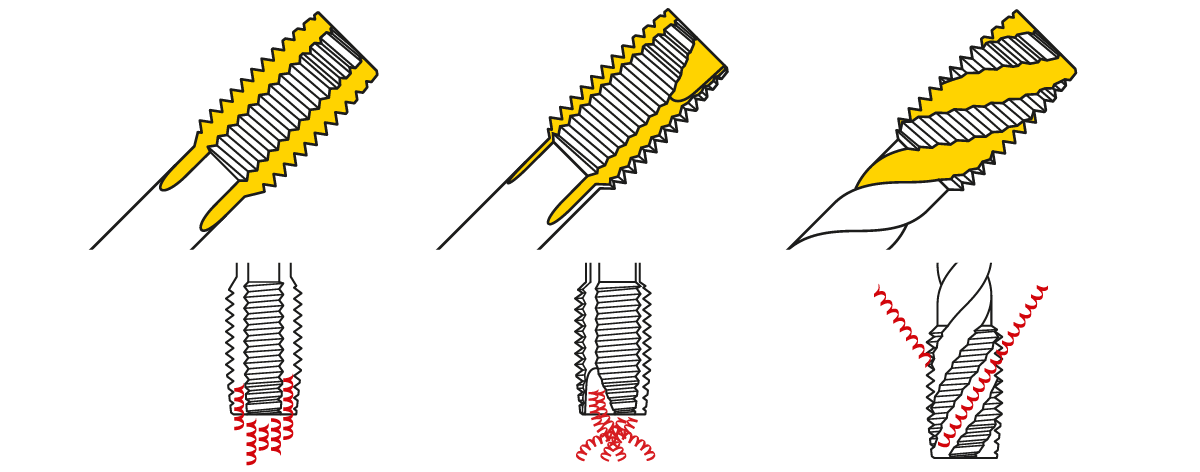

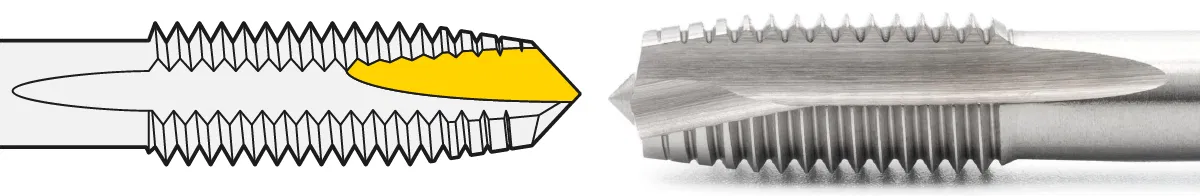

The threads are not yet fully developed at the tip of the tap. This area is referred to as the lead. The teeth of the lead do all the cutting work, the following, fully formed threads are only used for guidance. The length of the lead has an effect on which holes and materials a tap is suitable for. You can find out more about lead shapes here.

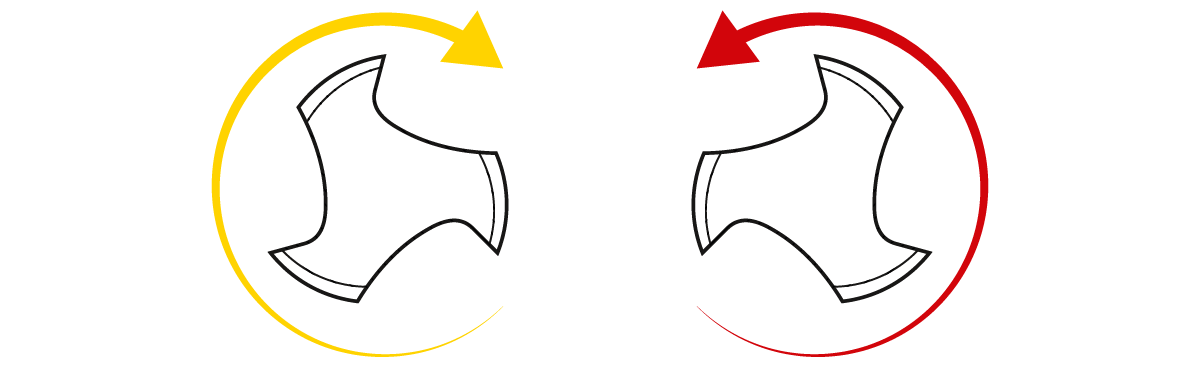

Direction of rotation

The direction of rotation indicates the direction in which a thread is cut. Most threads are right-hand threads. This means that when you screw in a screw, you turn it clockwise. However, left-hand threads are also used for certain purposes, e.g. on the right-hand pedal of a bicycle to prevent it from loosening automatically.

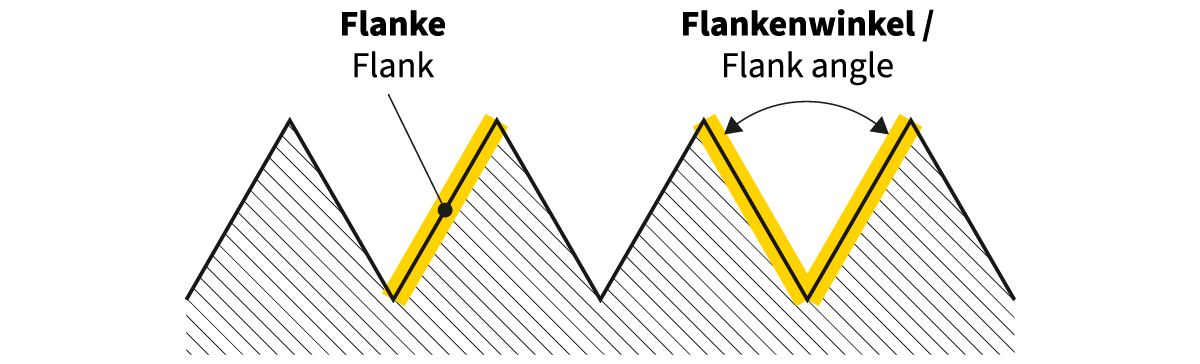

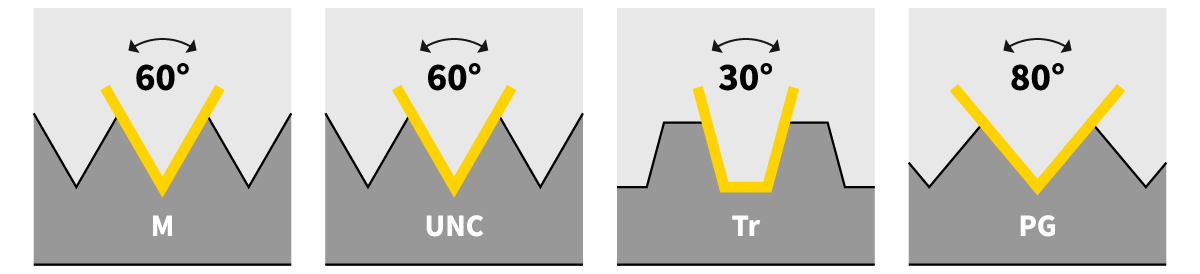

Flank

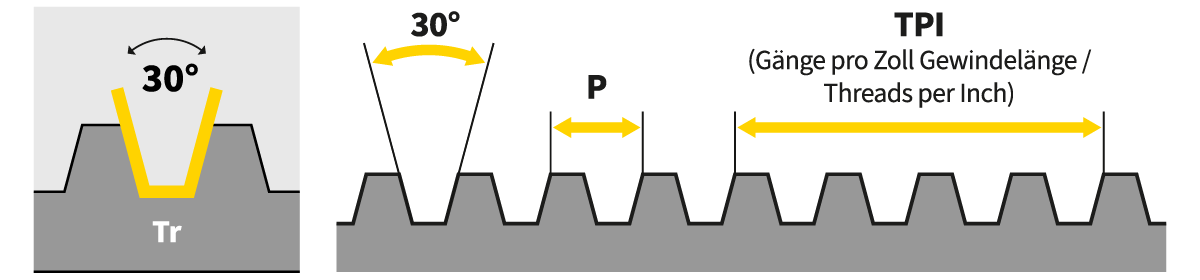

If we look at a thread in profile, the flanks are the lines that run from the base of the thread to the tip. They are primarily characterized by the angle at which they are positioned in relation to each other, which is one of the most important features of the thread.

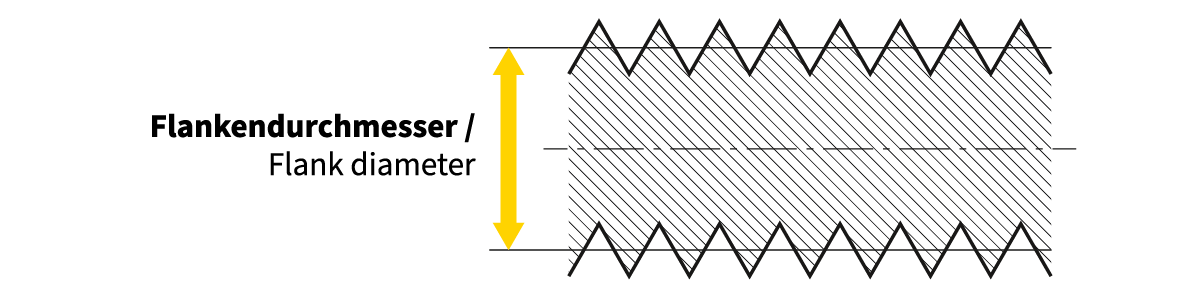

Flank diameter

The pitch diameter is one of the three diameters that are considered key parameters on the thread. It lies between the outer diameter and the core diameter and can be used to calculate the pitch angle of a thread.

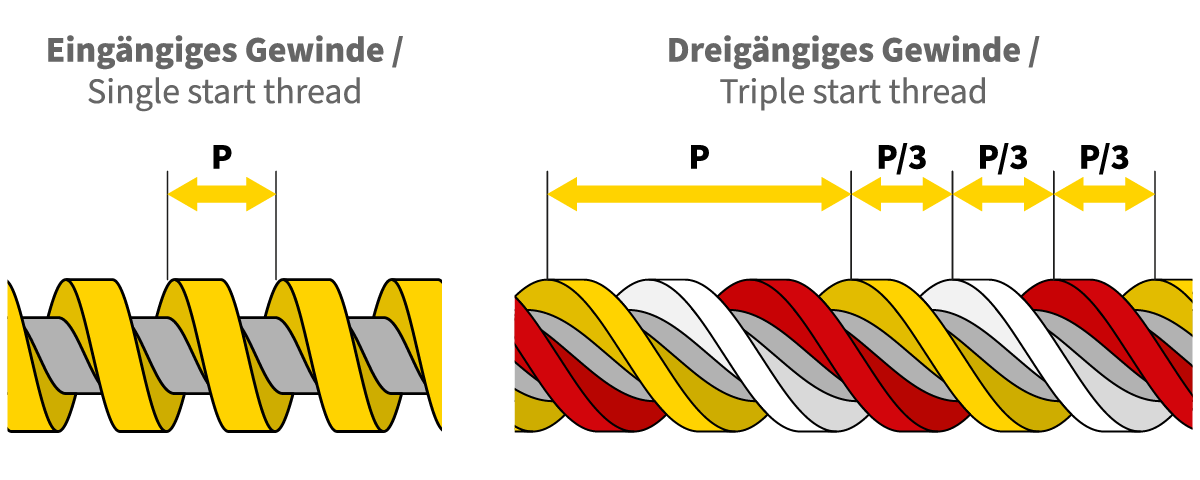

Number of threads

The number of threads indicates how many threads make up the thread. Typically, a thread has only one thread. In certain cases, however, threads can also have two, four or even more threads. This increases the stroke of the thread. We explain exactly how this works in our blog post on multi-start threads.

Thread types

The term thread types is used in various ways. It can refer to the various thread standards, which include the metric ISO thread. However, it can also be used to differentiate between threads of different types, e.g. fastening and movement threads.

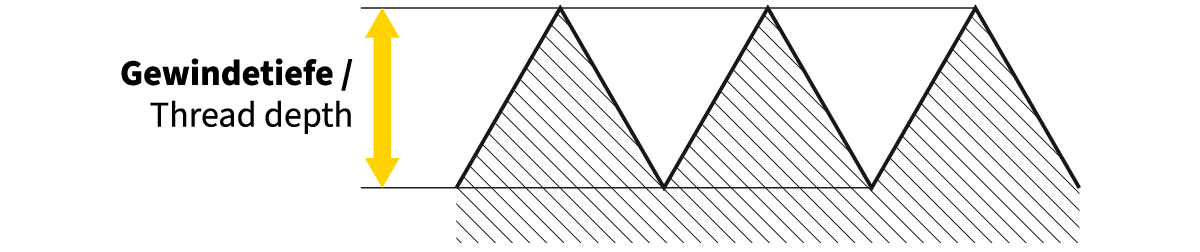

Thread depth

The thread depth describes the distance between the thread valley and the tip of the thread perpendicular to the axis. This is particularly relevant for thin-walled components, where there must be sufficient space for the fully formed threads. Sometimes the term is also used to describe how deep a thread is cut into a component.

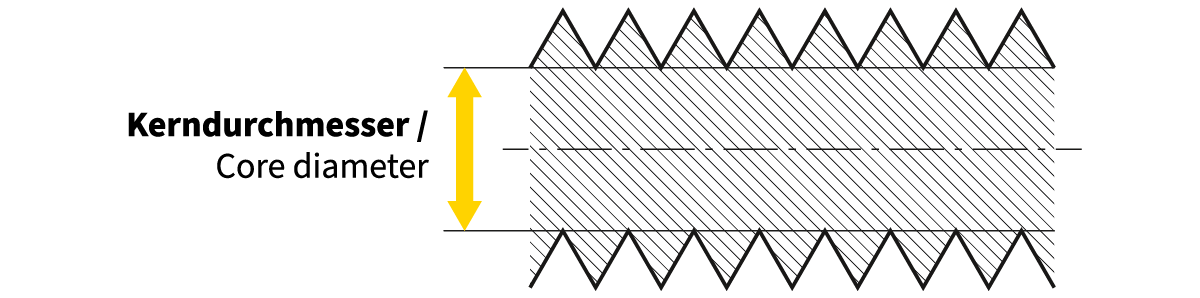

Core diameter

The core diameter is the smallest of the three diameters on the thread. It results from the distance from one thread root to the thread root on the exactly opposite side of the thread.

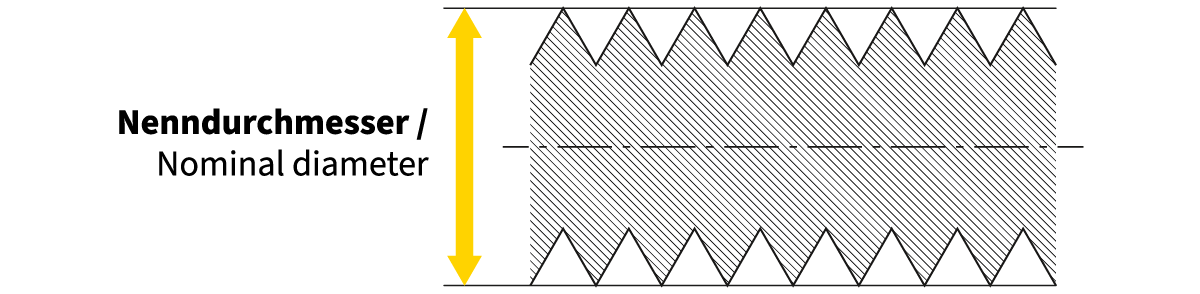

Nominal diameter

The nominal diameter is the largest of the three diameters on the thread and can also be referred to as the outer diameter. For most thread types, the nominal diameter is part of the thread designation. The metric ISO thread M 8, for example, has a nominal diameter of 8 mm.

Groove

The grooves on a tap are there to collect the chips and transport them out of the hole. They are also used to distribute lubricant. Depending on the application, flutes can have different shapes. You can read more about this topic here.

Profile

The thread profile comprises a compilation of all important parameters on the thread. It is mainly shown as a cross-section through the thread or tap, which provides a side view of the threads.

Peel cut

The skiving chamfer is a special form of chamfer on a tap. This is the B lead form. The chip is rolled tightly through the skiving chamfer and removed in the cutting direction.

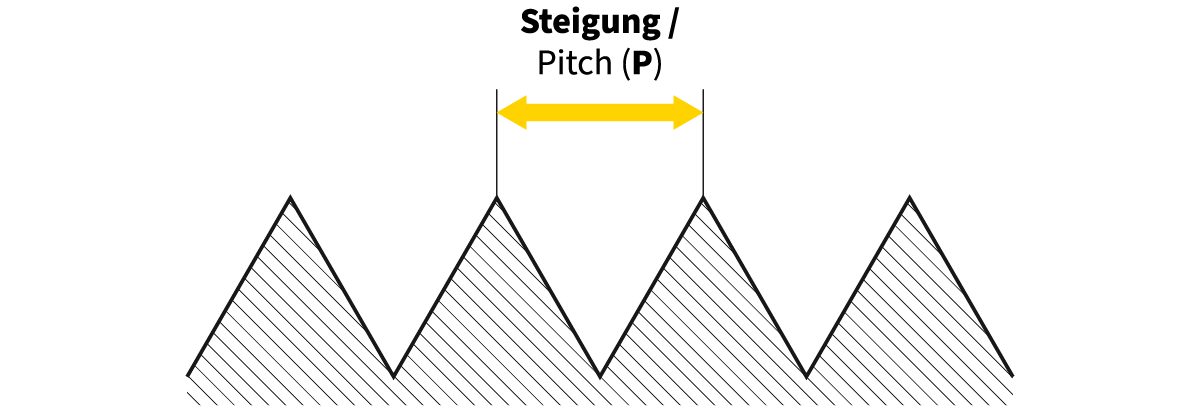

Pitch

The distance between two thread tips is referred to as the thread pitch. At the same time, the term also describes the distance that a component such as a screw travels per full revolution. For inch threads, the pitch is specified in the unit TPI (threads per inch), which refers to the number of threads per inch.

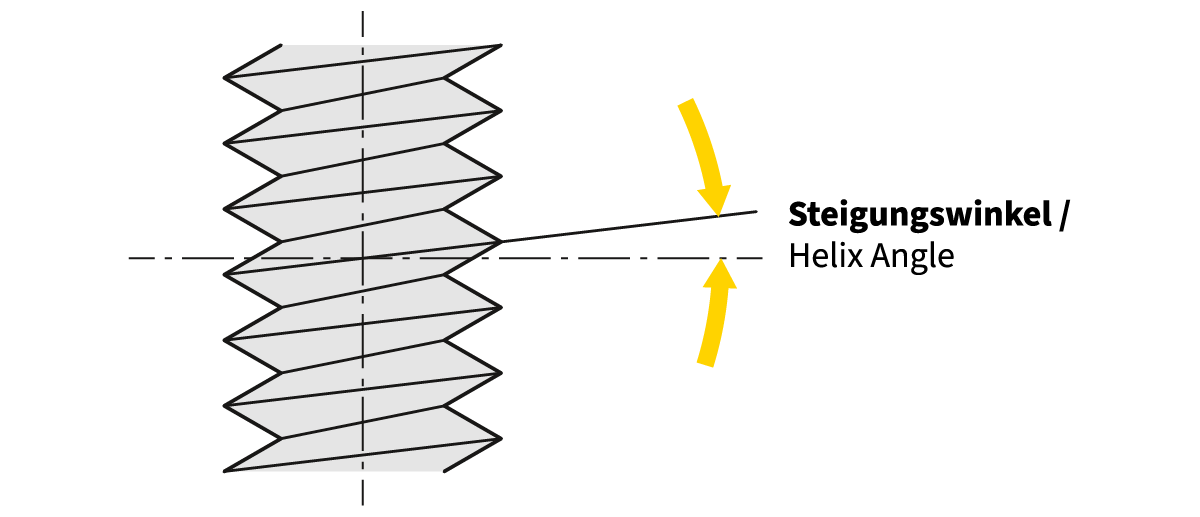

Pitch angle

To understand the lead angle, you have to imagine a thread as a straight ascending line, as if it had been "unwound from the bolt". The lead angle describes how much this line rises per full revolution. To calculate it, the pitch and the pitch diameter are required.

Division

The division corresponds to the distance between the thread tips of two adjacent threads. For single-start threads, it is identical to the pitch and is therefore of no further significance. However, it is always specified for multi-start threads. In this case, the division is the pitch divided by the number of threads.

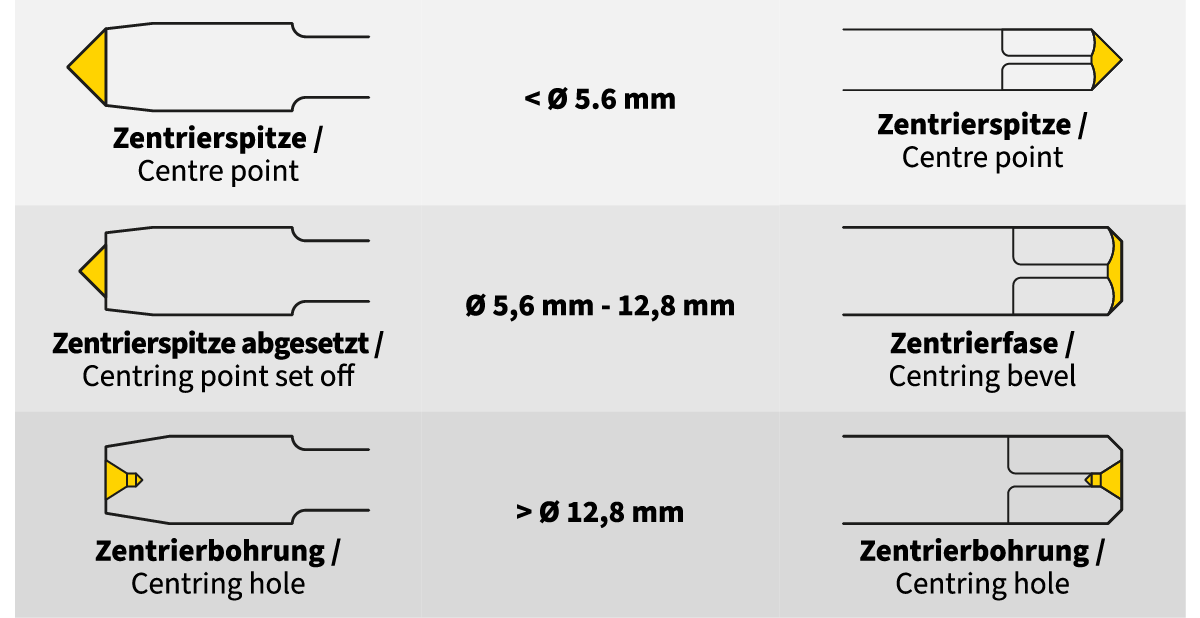

Centering

The centering describes the design of the thread tip and the shank. It is primarily dependent on the diameter of a thread.

Inch thread

In addition to metric threads, there are some types of threads that are described using the inch unit of measurement. These are mostly threads from the Anglo-American world, such as the British Standard Whitworth or the Unified National Thread. In addition to the unit of measurement, it should also be noted that the pitch is specified as the number of threads per inch.

Do you have further questions or are you missing a term in our overview? Then give us a call or use our contact form! And in the BAER online store you will find a wide range of threading tools for every application. Take a look for yourself!