Thread-Forming Screws – An Alternative to Thread Cutting?

In today’s world, the goal is almost always to make work processes as efficient as possible. That includes reducing the number of work steps required without compromising the quality of the final result. One such approach involves screws that can create their own thread.

It sounds tempting: screws you can simply drive into a hole without cutting a thread beforehand. That’s exactly what thread-forming or thread-rolling screws promise. But can it really be that easy? And if so, why do we still need taps at all? We'll answer these and other questions in today’s blog post on thread-rolling screws.

How Do Thread-Rolling Screws Work According to DIN 7500?

These special screws don’t cut the thread into the material like a tap does—they form the thread through deformation. That means no material is removed, and therefore, no chips are produced. You simply screw the fastener into a hole, and the threads are formed automatically by displacing the material.

Once the thread is created this way, the screw can be removed and reinserted as needed. Since thread-rolling screws usually match common thread types, they can even be replaced with standard screws. Up to this point, the method sounds quite practical.

What Should Be Considered During Installation?

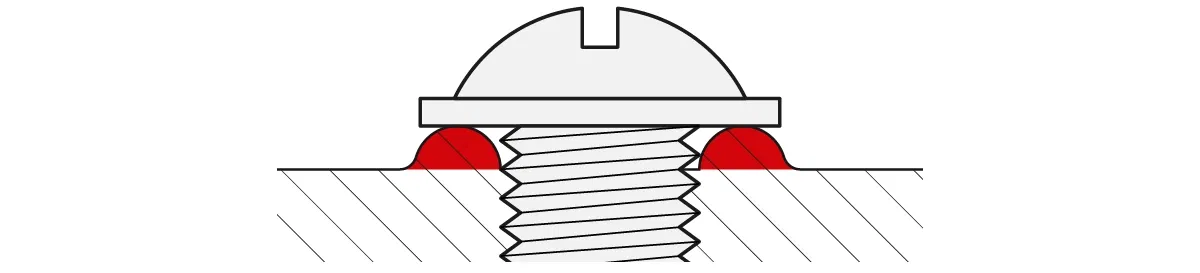

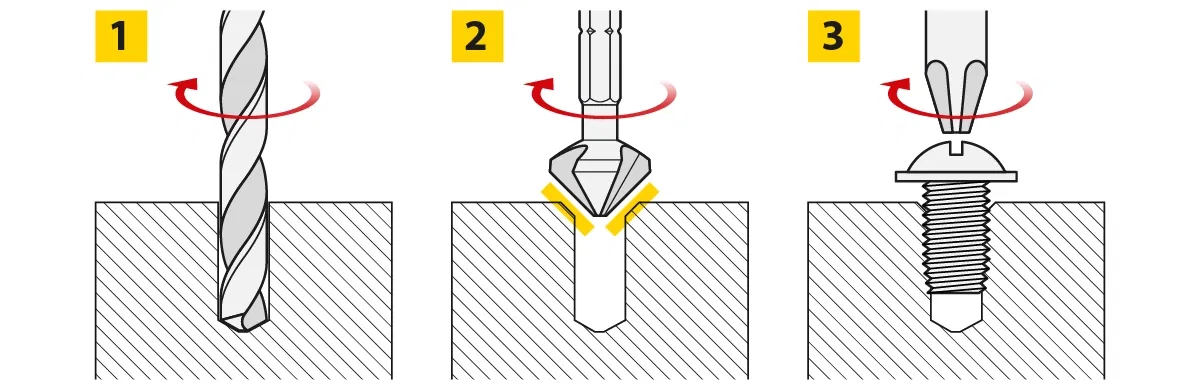

Just like thread cutting, the installation of thread-rolling screws requires a core hole that must be pre-drilled with the correct diameter. So you still can't skip this step. In addition, a ridge may form at the edge of the core hole. The displaced material has to go somewhere and may be pushed upward depending on the material and thread size. To ensure a clean result, it might be necessary to countersink the core hole—something that’s not always required when cutting threads.

After preparing the core hole, you simply drive in the screw. This works for both blind holes and through holes and can be done with a handheld or stationary machine. You only need to apply the appropriate pressure when starting.

What Are the Advantages of Thread-Forming Screws?

The use of thread-rolling screws actually sounds quite uncomplicated. Accordingly, these handy little components offer several benefits. Three aspects in particular stand out.

Non-Cutting Process

Thread-rolling screws offer all the advantages generally associated with forming processes for thread production. Since no material is removed, no chips are created, and there’s no risk of chip-related problems. In addition, the material fibers aren’t severed, which results in a very smooth surface. You get the same effect when using a thread-forming tool.

Play-Free Thread Engagement

The resulting female thread fits the screw thread perfectly and without play. This leads to excellent self-locking properties, meaning the screw remains securely fastened even in high-vibration environments. So when using thread-rolling screws, you don’t need to worry about fits or tolerances. On the other hand, there are screw joints where a little play is desirable—which, of course, can’t be achieved with thread-rolling screws.

Cost-Saving Potential

Back to efficiency: especially in mass production, thread-rolling screws offer multiple ways to reduce costs. First, there’s no need for a separate thread-cutting step, which saves significant time. Thanks to the excellent self-locking effect, you may also be able to eliminate additional thread-locking components. While thread-forming screws tend to be more expensive than their conventional counterparts, the economic advantage becomes significant only when processing large quantities.

Can Thread Cutting Be Replaced by Thread-Forming Screws?

Does this mean your tap is obsolete? Absolutely not! Thread-rolling screws have not only advantages but also several limitations.

Limited Use Cases

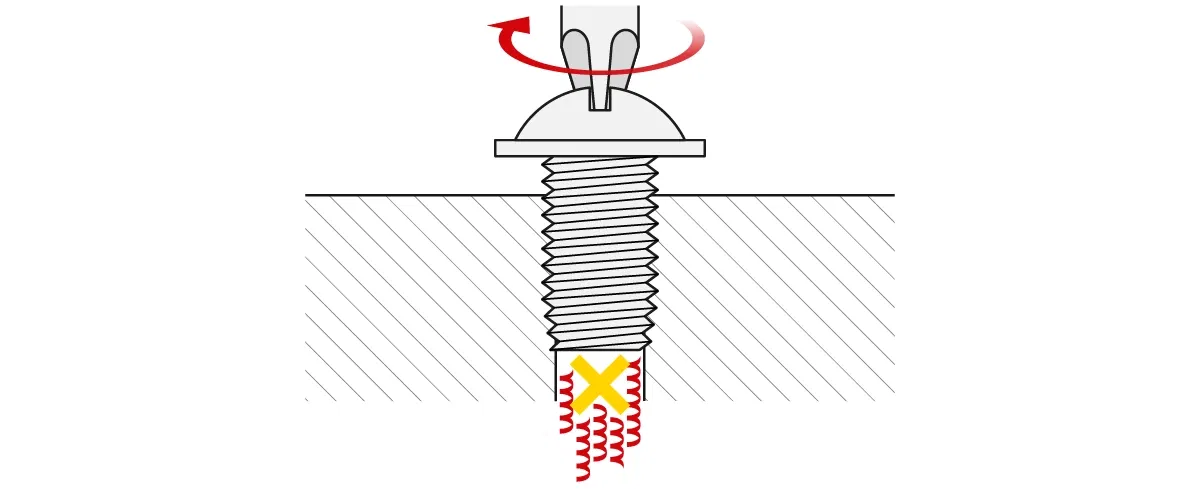

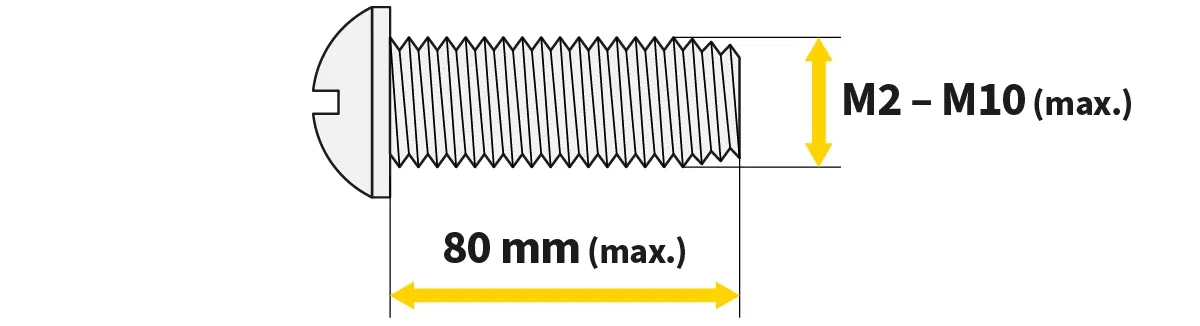

Not all metals are suitable for thread-rolling screws. They are mainly used with light metals, such as sheet metal. Thread diameters and lengths are also limited, which restricts the range of potential applications from the outset.

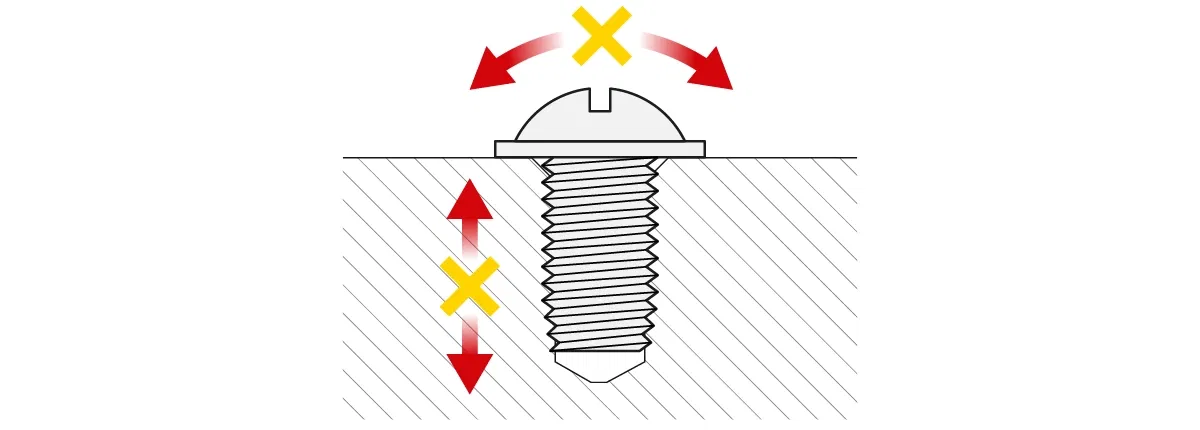

Reduced Connection Strength with Frequent Use

Frequent tightening and loosening of these screws can reduce the strength of the connection. It’s also possible that, when reinserting the screw, the alignment may be off, and instead of using the existing thread, the screw damages it.

Thread-Rolling Screws for DIY Use

These limitations mean that before using thread-rolling screws, it’s important to calculate whether their use is actually worthwhile. In mass production, they can indeed be beneficial. But for a tradesperson or DIYer who only occasionally needs to cut threads, the advantages probably won’t outweigh the drawbacks.

So the verdict remains: a high-quality tap gives you unbeatable flexibility. You can create any type of thread, without limitations on size, and work with a variety of materials such as steel or different plastics.

Still looking for the perfect tap for your next project? Then check out the BAER online shop. There you’ll find top-quality threading tools, accessories, and many other products at unbeatable prices. Our friendly service team is happy to help—by phone or conveniently via our contact form. We look forward to hearing from you!