Thread Pairing: When Do Threads Match?

It’s in the nature of things that a thread can only function with a matching counterpart with a few exceptions. A screw needs its nut or another threaded counterpart, and a leadscrew only works through the interaction between a threaded rod and a leadscrew nut.

For this to work, the two threads must mesh perfectly. A fact so obvious it is sometimes overlooked. Threads form pairs, and like with all pairs, it is essential that they fit well together for the connection to be durable. But when is that the case, what needs to be considered, and what can you do if threads simply don’t fit? We explain it all in our blog post on thread pairing.

These Dimensions Matter

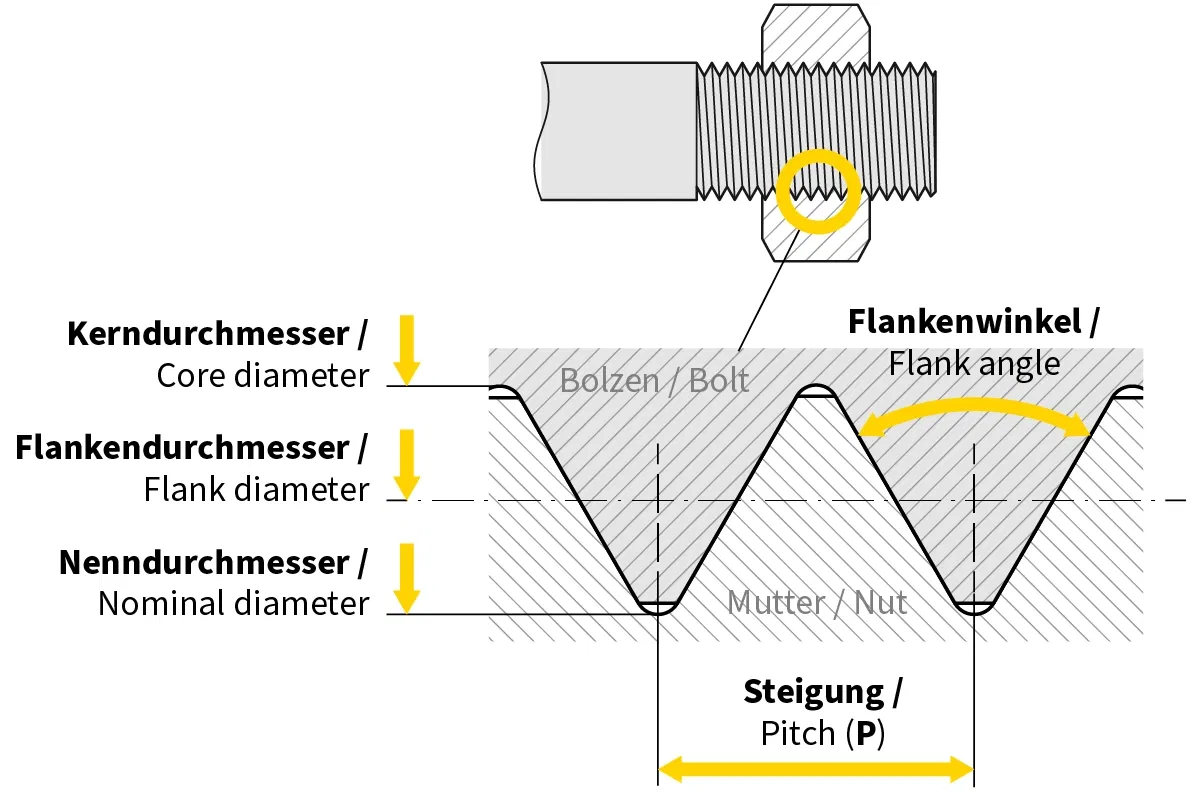

For a successful thread pairing, external and internal threads must engage smoothly. Compatibility only exists when a whole set of geometries and dimensions match. These include the flank angle, diameter, and thread profile. If this is not the case, you’ll usually notice right away because the screw won’t turn. However, some different thread types have very similar dimensions, making them hard to distinguish at first glance.

By the way, there are also cases where the mating thread is only created when a screw is inserted. A classic example of this would be wood screws or sheet metal screws, which can be driven directly into the material without pre-threading. In such cases, thread pairing is automatically guaranteed.

Can Different Thread Types Be Combined?

Thread standards ensure successful thread pairing by precisely defining thread dimensions. This guarantees that you can buy a replacement screw at any hardware store and it will fit just like the original. You just need to choose the correct standard and the right diameter.

But are only components with the same thread standards compatible, or can you mix them? Some thread types seem quite similar at first glance, such as the metric coarse thread and the American UNC thread. Their dimensions are sometimes so close that you might think screws of both standards are interchangeable.

But on closer inspection, you’ll notice slight differences. These may only be in the millimeter range depending on the thread size, but that’s enough to cause threads to jam or get damaged.

So, even if components appear compatible at first and a screw might even thread in – mixing different thread standards is never a good idea and can, in the worst case, pose a real safety risk. The only exception to this rule applies to certain types of pipe threads, which we’ll discuss later.

The Role of Tolerances

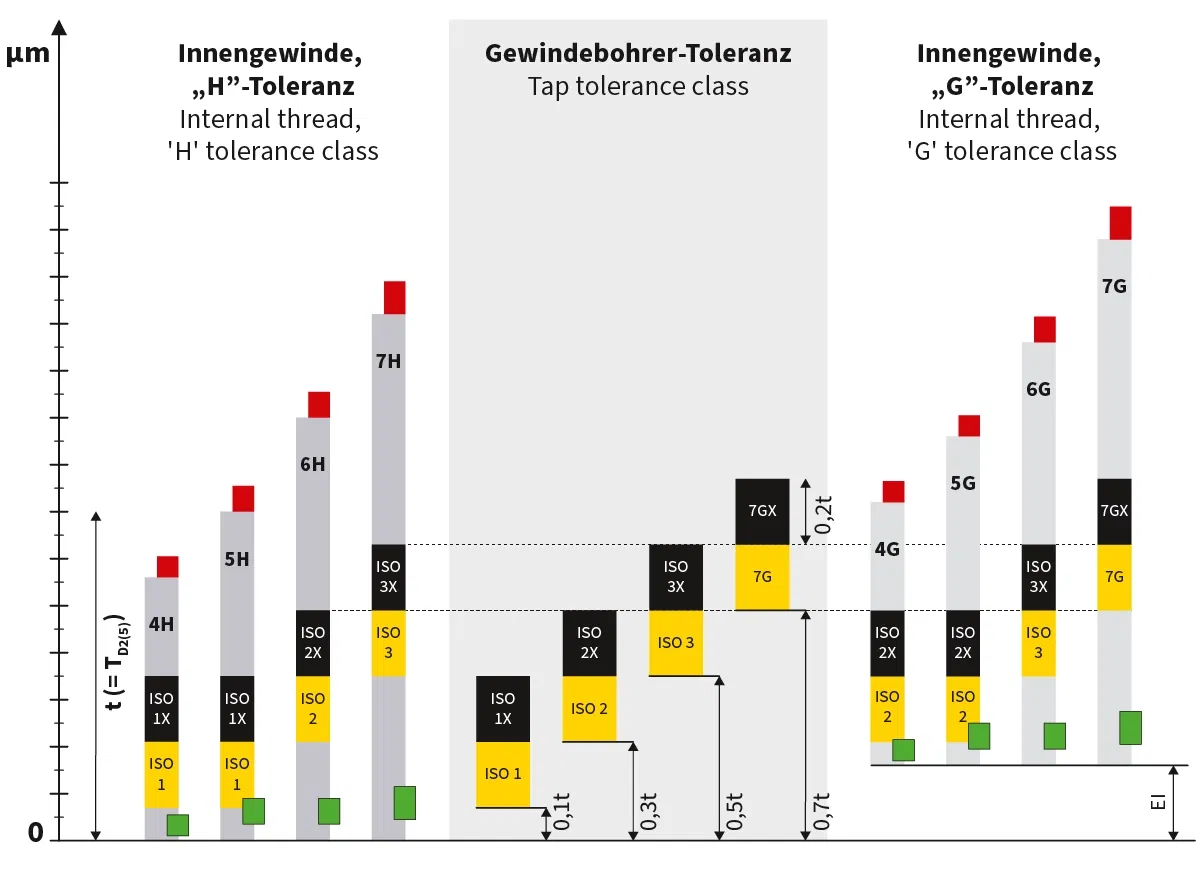

A challenge in thread pairing is that no manufacturing method is perfect. The idea that screws made in factories around the world all have exactly the same dimensions without deviation is simply unrealistic. To ensure that threads of the same standard and size still fit perfectly, we have to allow some tolerance in dimensions.

This allowable deviation is called tolerance. Tolerance defines how far the actual measurement can deviate from the nominal value. It is specified using tolerance classes, which consist of the tolerance grade and the tolerance position. The grade defines the allowed deviation, the position describes the offset from the zero line.

Tolerance classes can vary greatly depending on the thread standard. Sometimes a thread connection needs some clearance, for example, to allow room for coatings. In other cases, such as with the MJ thread in aerospace applications, tolerances are kept very tight to ensure high precision.

Special Case: Pipe Threads – Which Fittings Are Compatible?

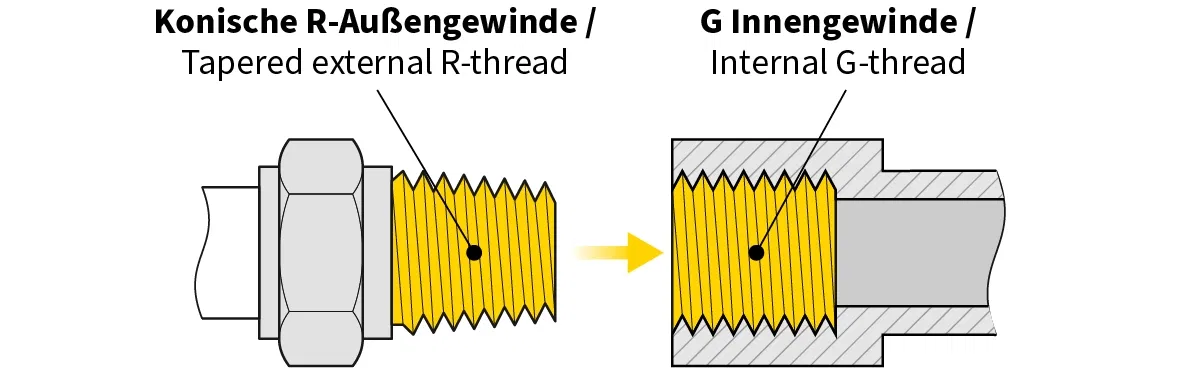

In the world of pipe threads, it is more common to combine fittings of different thread types. But even here, combinations remain within narrowly defined limits to avoid compromising thread compatibility. That’s especially important with pipe threads because sealing the system is critical.

Especially the G thread (ISO 228) and the R thread (ISO 7/1) can be combined in different ways. For example, a tapered R external thread can be paired with a G internal thread. Depending on the combination, various sealants may be needed to ensure a leak-proof connection. Adapters are also commonly used – a simple and reliable way to join two different pipe thread types.

How to Find the Right Thread Pairing

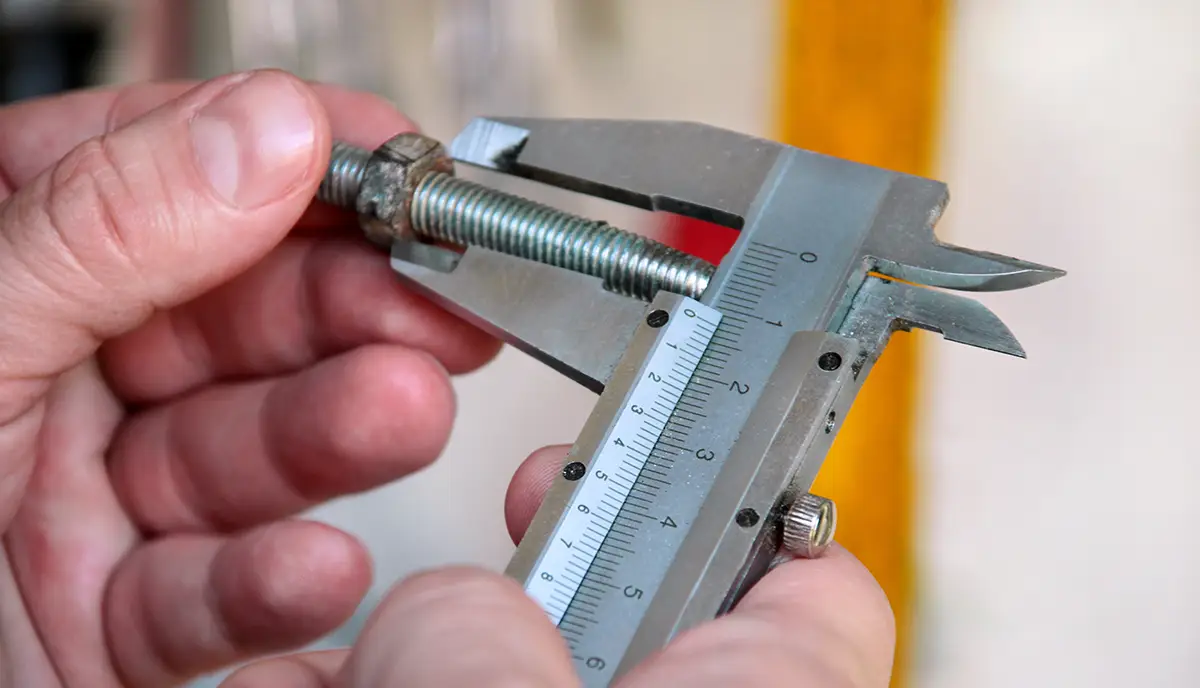

Let’s say you’re doing a repair at home and need to replace a broken screw – how can you make sure that the new replacement screw will result in a perfect thread pairing? First, you need to identify the thread type and the size. The size can be determined by measuring the outer diameter with a caliper. That leaves the thread type.

For standardized fasteners in Europe, it’s safe to assume you’re dealing with a metric ISO thread. Try a matching screw by gently threading it into the counterpart without using excessive force. If the screw doesn’t fit, you can measure the pitch using a thread gauge. The combination of pitch and outer diameter should then lead you to the correct thread standard.

Perfect thread pairings for every thread type are easy to achieve with high-quality threading tools from BAER. Visit our online shop and explore our wide range of products, fair prices, and fast delivery times. For questions and suggestions, our customer service is happy to assist you by phone or via contact form.