Thread Tapping Machine – Yes or No? Machines & Hand Tools for Threading Technology

What are your priorities when it comes to thread cutting? That will partly determine which machine you might want to use for thread production. In addition to a specialized thread tapping machine, there are actually many other options.

For some professionals, flexibility is the top priority. If you frequently travel from one customer to another and face new working conditions at each site, your tools need to adapt. It's a different story in series production, where ideally everything runs the same every time. Here, speed and consistent quality are the main concerns.

As a DIYer, there are a few additional factors to consider. How often do you cut threads, how much space do you have available, and what kind of budget are you working with? These are questions you’ve probably asked yourself. Today, we’ll take a closer look at whether a thread tapping machine might be worth it for you and what alternatives you have.

Thread Tapping Machine vs. Hand Tools: What Are the Differences?

First, we need to determine whether you even need mechanical support. After all, thread cutting can also be done by hand. Both methods have their pros and cons, and of course, you can combine them – for instance, doing only the rework or repair of threads by hand while using the machine for everything else.

Thread Cutting with a Machine

A machine takes a lot of the work off your hands. First and foremost, there’s the direct effort required – which may be impossible with muscle power alone depending on the material. A machine also helps guide the tool steadily, align the workpiece accurately, and hold it firmly in place. Depending on the model and manufacturer, machines may offer additional features like automatic feed. And you simply can’t match the speed of a machine when threading manually.

On the other hand, a machine has to be purchased first. When it comes to thread cutting, a thread tapping machine isn’t your only option. You can also clamp taps into a stationary drill press – although that’s not exactly mobile.

Thread Cutting by Hand

Manual thread cutting gives you lots of freedom when it comes to location. With the right hand tap and holding tool, you can work virtually anywhere, regardless of your workshop setup or power supply. You can also change locations easily. Even hard-to-reach areas on permanently installed parts that can’t be clamped into a drill press are accessible. This is a major advantage when re-threading threads.

On the downside, there are strict limits to what you can handle in terms of a material’s machinability. There are, of course, different tools for different materials and thread sizes, but not every cutting task can be done by hand. It also takes some practice to produce a truly perfect thread manually – and it’s certainly not fast. So manual thread cutting is best for occasional use or special situations.

Automated Threading Processes: When Is Which Investment Worthwhile?

If you decide to go for mechanical support, the next question is: which device should you buy? Factors such as weight, motor power, and achievable speed are all relevant.

A table or drill press has the advantage that it can also handle many other tasks. So it’s not only worthwhile if you cut threads frequently. The selection is wide, and you can choose from a range of sizes and features, expanding your setup with suitable accessories.

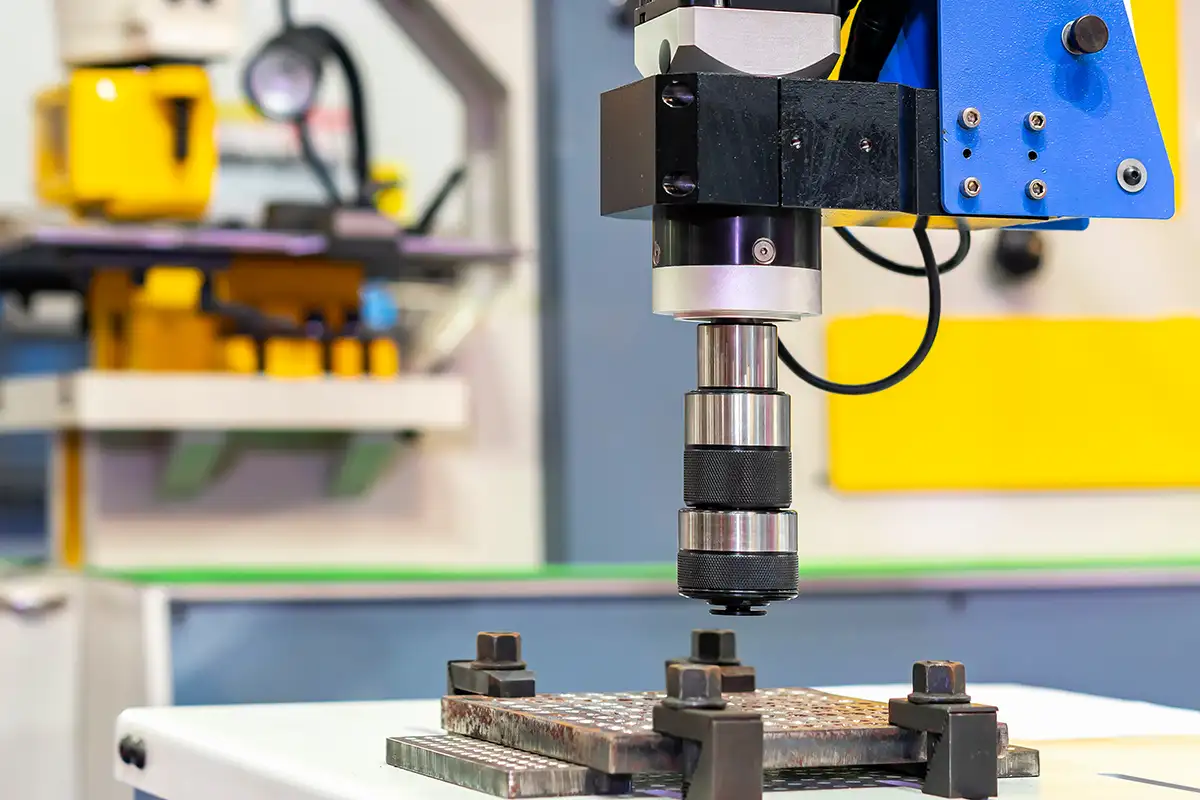

A thread tapping machine, by contrast, is specifically designed for tapping. It features a movable arm that can be locked into different positions, offering flexibility with tool entry angles. Some versions even allow you to clamp twist drills and countersinks, letting you handle all the prep work for thread cutting with the same machine.

Still, the thread tapping machine is purpose-built. It’s excellent for producing threads, but it’s not intended for other tasks. The investment makes the most sense for professionals and industrial production of threads.

Modern CNC Technology for High-Precision Threads

In professional settings, CNC machines are often used. These computer-controlled machines work quickly, precisely, and reliably. In series production, where every product must be produced with consistent quality, such equipment is indispensable.

However, for a CNC machine to do its job well, it first needs to be programmed – and that’s no easy task. Various parameters must be calculated and entered correctly and in the right place. If the result doesn’t meet expectations, troubleshooting can be tedious, especially if you’re not a pro. That’s why CNC machines are better suited for industrial halls and large workshops than your basement hobby room.

Already know how you want to produce your threads? Then you'll find the perfect tool in the BAER Online Shop. From hand tap sets to professional tools for demanding materials, we have everything you need for your project. Full product details can be found on the item pages – or just ask our customer service!