Threads in Cable Glands: Everything You Need to Know

Without threads, there would be no fastening screws—that much is clear. But other components also function only thanks to the special properties that threads offer. Especially those that need to hold securely but also be removable. Like cable glands.

As components used in electrical installations, cable glands must meet a number of safety criteria and also be easily interchangeable and replaceable through standardization. Naturally, threads are a key part of the picture! Let’s take a closer look at where and which thread types you can expect to find on cable glands.

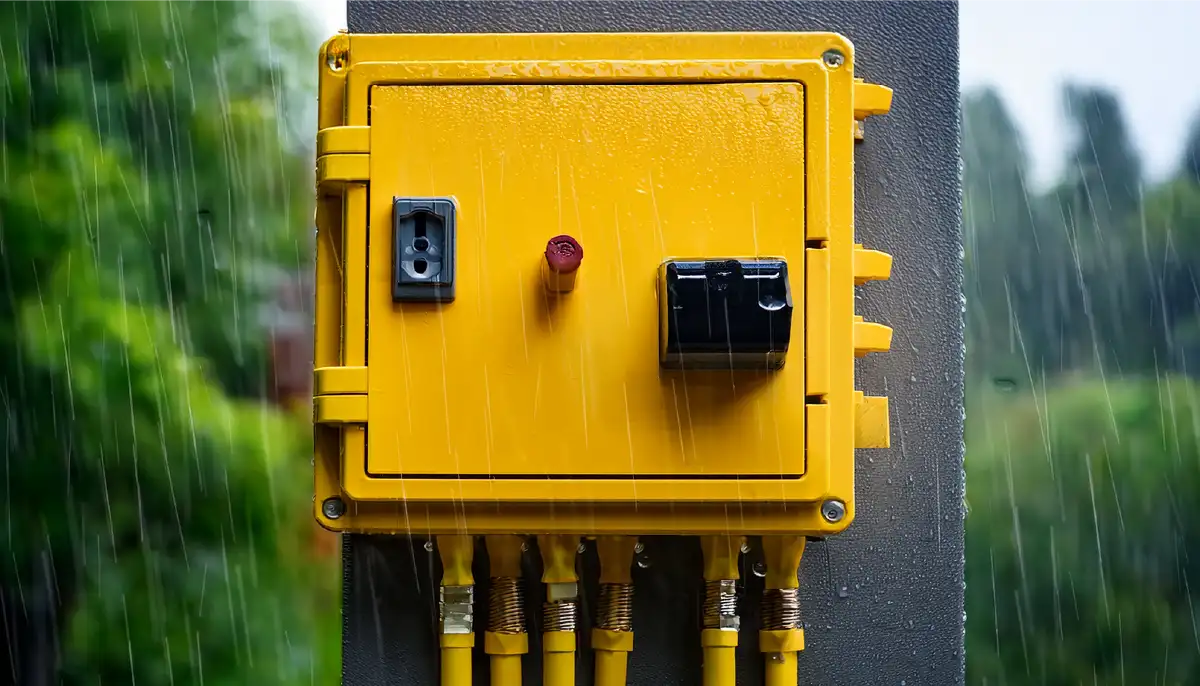

Where Are Cable Glands Used?

Electricity has become indispensable in every area of life. Unfortunately, it (still) cannot be transmitted wirelessly, so our daily lives rely on an extensive network of wires and cables. These all eventually end up in distribution boxes, control cabinets, or junction boxes.

The problem? The cables need to go in, but dirt, dust, and moisture must be kept out. That’s where cable glands come in. Acting as a cable entry, they secure the critical point where the cable passes through the housing wall, provide a proper seal, and protect the cable from mechanical influences.

How Does a Cable Gland Work?

Even though there are different types of cable glands, their basic functionality is usually the same. When properly installed, they reliably seal the enclosure and provide strain relief for the cable. Depending on the application, cable glands may differ in materials used or be equipped with additional sealing inserts. All requirements for electrical installation cable glands can be found in standard DIN EN 62444.

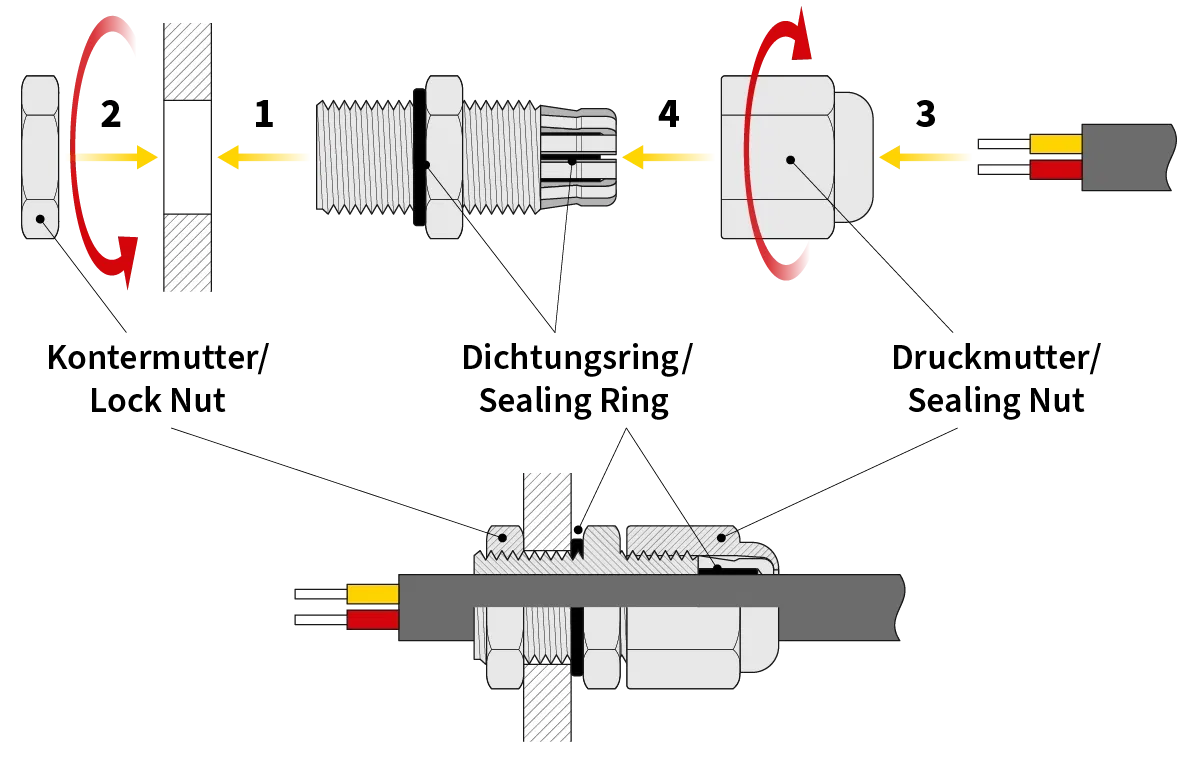

Mounting Cable Glands Using Threads

Cable glands have two threads. The first is used for mounting to the housing. The cable gland is inserted through the opening and secured from the inside with a locknut. Then the external compression nut is tightened to fix the cable in the cable gland. The clamping range for the cable remains adjustable.

Today, there are also versions that use a click system and can be installed entirely from the outside of the housing. Depending on where they’re used, cable glands are made from plastic or metals such as stainless steel or brass.

The Importance of Protection Rating

As with all electrical devices, the protection rating is important for cable glands as well. This is indicated by an IP code and describes how well the component is protected against mechanical impact and water. Common ratings for cable glands include IP 68 / IP 69K, meaning the component is dustproof and waterproof.

EMC Cable Glands for Electromagnetic Protection

A special type is the EMC cable gland, which prevents electromagnetic interference from affecting devices. In areas with high levels of electromagnetic radiation, sensitive components must be shielded to function properly. As the total number of electrical devices that can interfere with each other increases, the importance of EMC cable glands continues to grow.

These Thread Types Are Found on Cable Glands

There are primarily three thread types commonly found on cable glands: the metric thread for cable glands, the PG conduit thread, and the inch-based NPT thread.

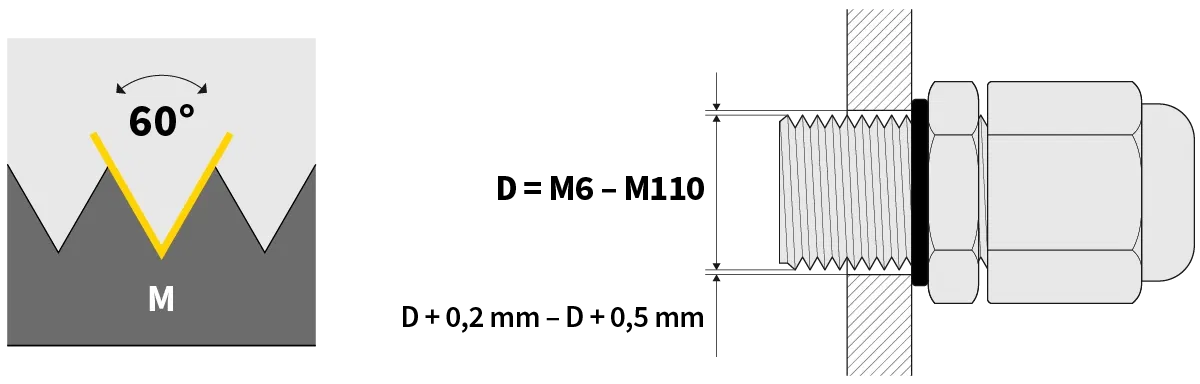

Metric Threads According to DIN EN 60423

The DIN EN 60423 standard defines a metric thread that is most commonly used in electrical installation products. It includes 14 outer diameters from M 6 to M 110, each with a corresponding pitch, which must be included in the designation, e.g., M 20 × 1.5.

The mounting hole for cable glands should match the thread's outer diameter, with a small permissible upward deviation. This tolerance increases with thread size—from 0.2 mm for M 6 to 0.5 mm for M 110.

The metric thread defined by DIN EN 60423 is the thread you’ll encounter most often in the European region when dealing with cable glands.

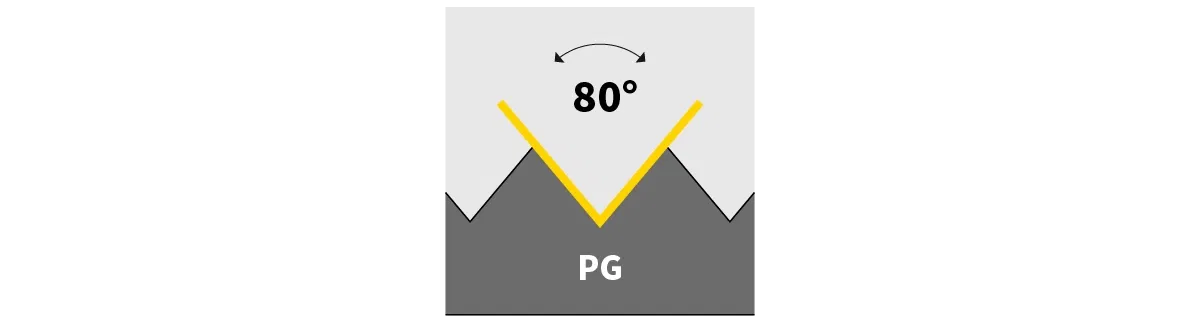

PG Threads

Before metric threads became widespread for cable glands, the conduit thread standardized by DIN 40430 was most commonly used. Today, only the metric thread described above should be used for new installations. However, the conduit thread hasn’t disappeared entirely.

You may still find PG threads in older components. In such cases, mixing old and new components is not possible, since PG and metric threads are not compatible. You must either work with the old standard—or, preferably—replace old components with new ones that use the metric thread.

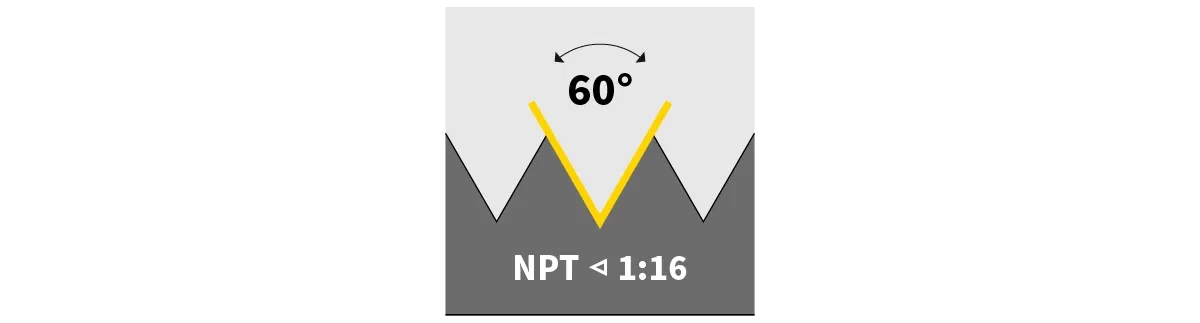

NPT Threads

You may also encounter NPT threads on cable glands. These come from the American market and are inch-based threads with a tapered form. While originally a type of pipe thread, NPT is also well-suited for cable entries due to its excellent sealing properties.

For NPT threads, the outer diameter is given in inches, and the pitch is specified in threads per inch. They are widely used as connection threads in the U.S. but can also appear in Europe through imported products.

Whether you're working with metric cable gland threads, conduit threads, or NPT threads—we have them all. If you’re looking for the right threading tools for your projects, be sure to visit the BAER online shop. There you’ll find not only high-quality products but also plenty of useful info and tables. And for any further questions or concerns, our customer service is always ready to help!