Threads in Plumbing and More

Threads always work the same way? That might have been true in the early days of threading technology. Nowadays, almost every field where threads play a crucial role has its own standards and requirements. This allows each threaded connection to be perfectly tailored to its specific purpose.

This great variety in the field of threading has many advantages and is indispensable in our modern world with its innovations and rapid developments. On the other hand, this also means that as a DIY enthusiast or professional tradesperson, you need a solid amount of technical knowledge to ensure that you choose the right thread for your project.

But that’s where we come in. Today, we are talking about threads in plumbing, heating, and air conditioning – in other words, all the threads used for fittings and fixtures, heating pipes, and garden hoses. These ensure that plumbing installations remain stable under pressure without leaking while still being flexible and easy to modify. What makes them special, what should you watch out for, and which types of threads should you choose? We answer all these questions and more in this blog post.

What Makes Threads in Plumbing, Heating, and Air Conditioning Special?

Why do pipes or radiator valves require different threads than, for example, a fastening screw? This has to do with the working environment. In the HVAC sector, threads appear wherever liquids or gases need to be transported. For safety reasons alone, the tightness of these connections is critical. Additionally, this industry prefers specific materials such as brass, which must also be considered in thread manufacturing. Accordingly, different types of pipe threads have developed internationally to meet these challenges with ease.

The Role of Sealants

Pipes and conduits must be sealed to prevent damage or safety risks. By nature, a thread represents the weakest point in a system because the material is inevitably interrupted at this location. Therefore, special measures must be taken at and within the thread to restore its tightness.

There are various ways to seal a thread. Some types of pipe threads are not cylindrical but conical. This allows two pipe ends to wedge into each other and create a metallic sealing threaded connection.

Depending on the application, sealants can also be used additionally or alternatively. These are available in various forms, such as paste, thread, or tape. A traditional method is the use of hemp as a sealant. The chosen product can either be applied directly to the thread or seal the connection from the outside. The extra effort is worth it, as a suitable sealant effectively prevents water damage and ensures that all your pipe connections function as intended.

Which Materials Are Used for Threads in Pipes and Fittings?

The HVAC sector imposes high requirements on the materials used. These must be easy to work with while also being corrosion-resistant and able to withstand high temperatures. If you need to create or repair a thread, you first need to determine what material your pipe or fitting is made of.

Common materials include stainless steel and brass – two metals with very different properties, each requiring the appropriate threading tool. Brass is typically easy to identify by its color, which varies from brownish to bright yellow depending on the zinc content.

However, many fixtures are chrome-plated, making them visually harder to distinguish from stainless steel. If you are unsure, you can lightly file the material at a concealed spot. In any case, you must use a tap or die suitable for brass.

The Issue with Inch Sizing

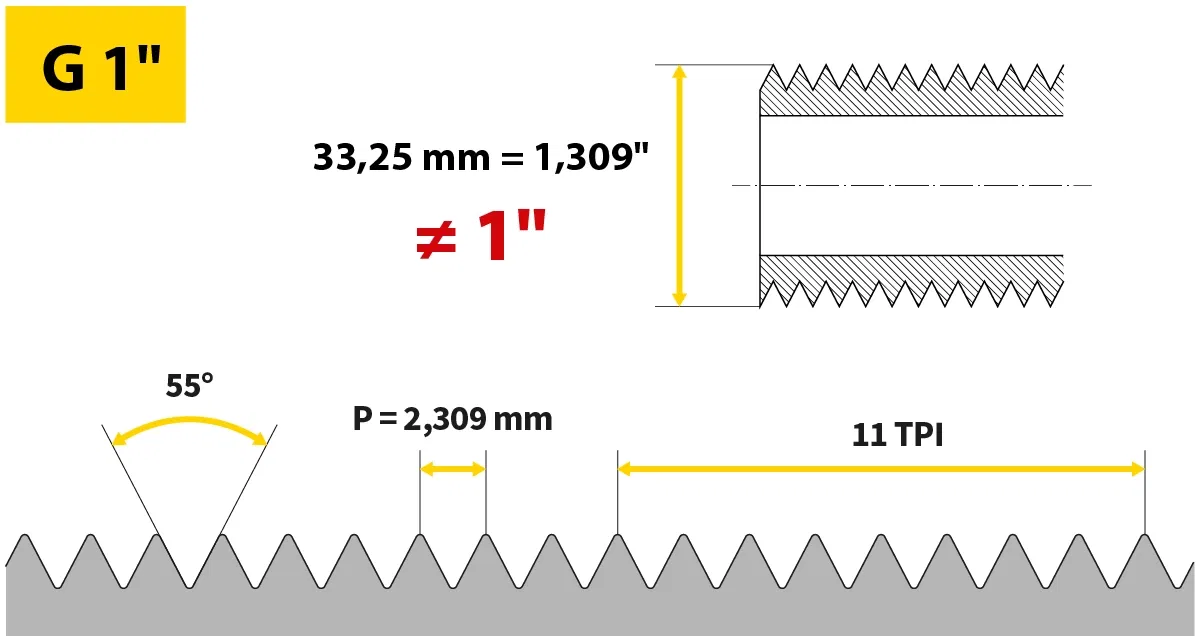

When working with a pipe, it is crucial to pay close attention to the correct outer diameter. The thread designation is given in inches, but this is actually a nominal size. Historically, the inch specification originally referred to the inner diameter, as this was more important for pipes. Advances in material technology have made pipe walls increasingly thinner, altering the relationship between inner and outer diameter.

However, the designation has remained the same, so today neither the external nor internal thread corresponds exactly to the stated diameter. You should think of the inch designation for pipe threads as a reference rather than an actual measurement. The best way to determine the real dimensions is by consulting a thread table.

R 1/2, R 1/4, or G-Threads: Different Types of Pipe Threads

Which thread table should you use? In fact, there is a whole range of pipe thread types. The most common type in our region is the G-thread, often referred to as the Whitworth thread. This is actually a British thread standard that has also gained widespread acceptance here. In addition to different versions of the Whitworth thread, there are also many American pipe thread types with highly specific applications. A detailed overview of the various types of pipe threads can be found in our blog.

Are you looking for taps, dies, and more for your threads in plumbing, heating, and air conditioning? You’ll find what you need with us. In the BAER online shop, we offer a wide selection of high-quality threading tools for all common pipe thread types in numerous sizes. Take a look and see for yourself. And if you have any questions, our friendly customer service is always happy to help.