Why flat threads are no longer used today

We always like to deal with perfectly sophisticated thread profiles and praise the engineers of yesterday and today for the precise detail work required to optimally match a thread to its intended use. However, there are also some designs in the history of threads that have not been able to establish themselves in the long term. However, there is often a lot to be learned from such cases and they are usually important intermediate steps on the way to our modern thread types.

That's why today we're going to take a look at a type of thread that you will probably never encounter in the wild. The flat thread is a relic from the early days of thread machining and is only used very occasionally today. What was it used for, what did it look like and what ultimately led to the flat thread being replaced by more modern thread profiles? We answer all these questions in this blog post.

What is a flat thread?

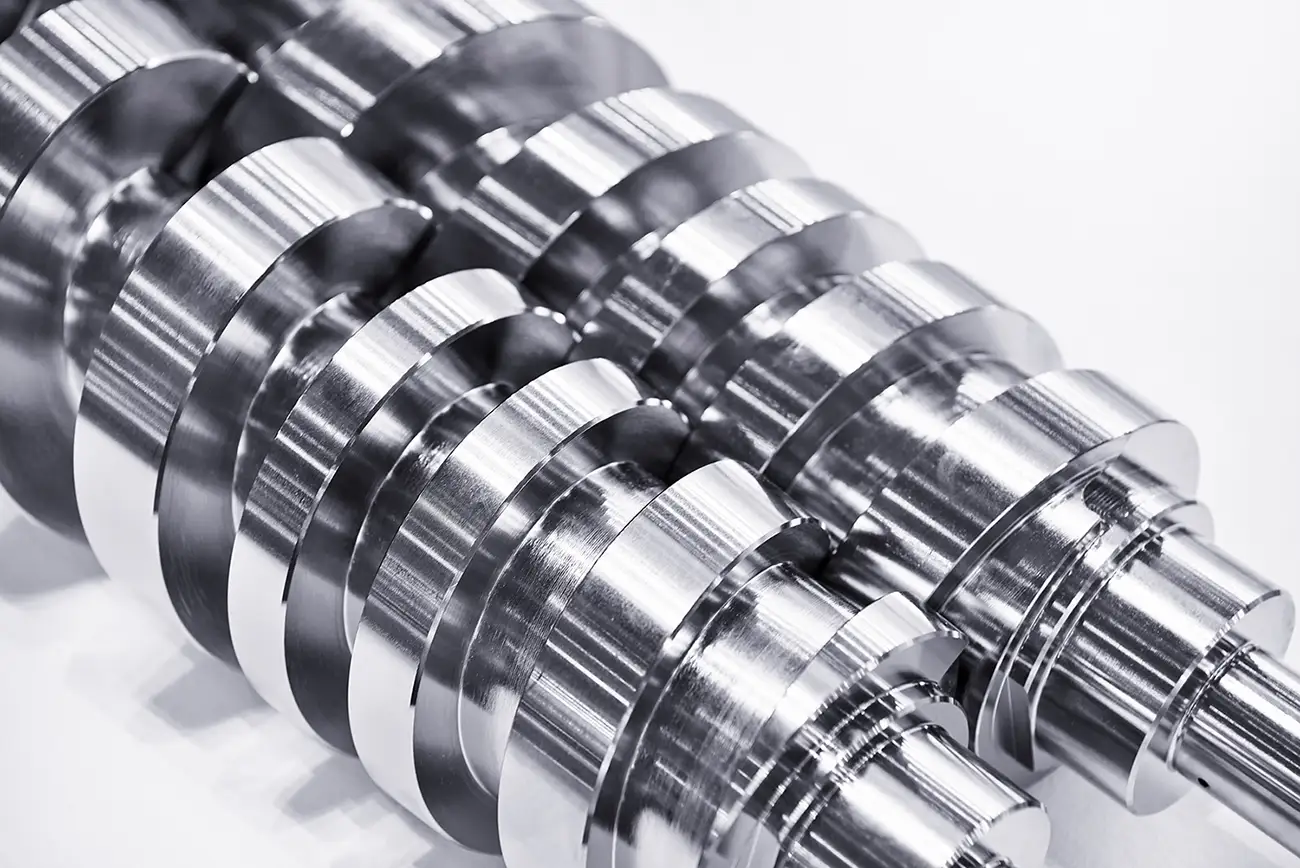

The flat thread is an early variant of a motion thread. It was already used in the 19th century in machines for lifting or threaded spindles to convert a rotary movement into an axial movement.

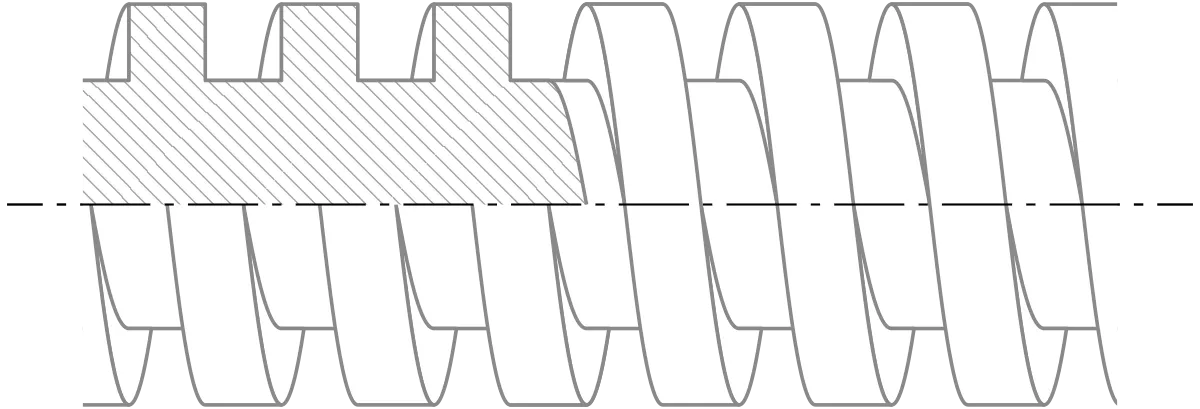

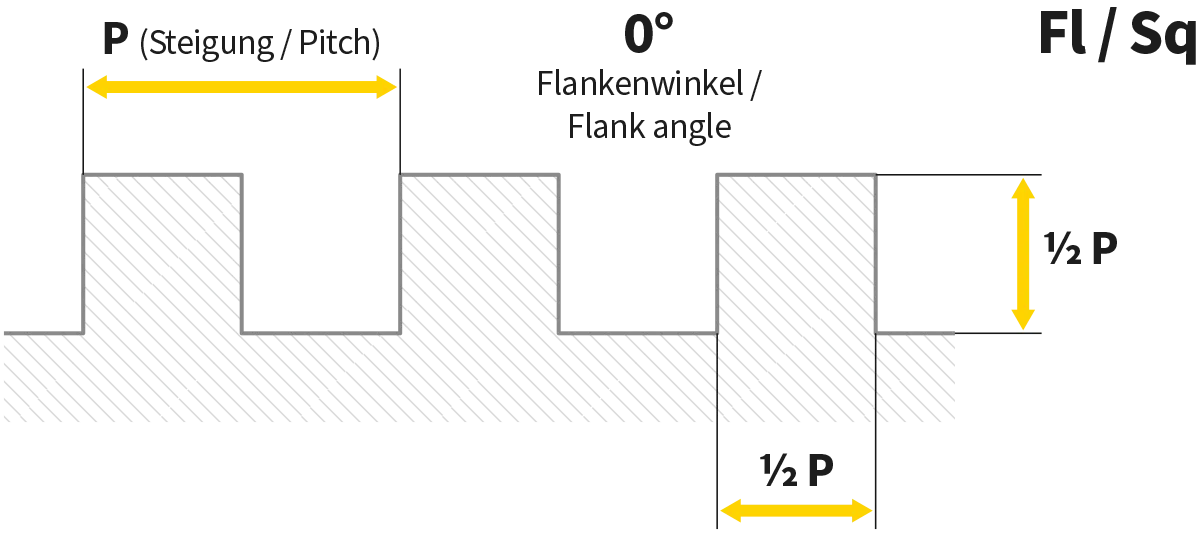

The profile of the flat thread is particularly interesting, as the flank angle is 0°. If you can't imagine it now, just think of a row of battlements on a castle wall. The flat thread has a profile that consists of squares arranged in a row with equally large gaps between them. It follows that the flat thread has no thread crest. So how is the pitch determined? The pitch of the flat thread corresponds to the distance between two equal corners on adjacent squares. The width and height of one of the squares each measure half of the pitch.

As the flat thread has not been part of the standard thread cutting repertoire for a long time, there is no current associated standard. The abbreviation for the flat thread is usually the letter sequence Fl, in English-speaking countries often also Sq for square thread. This is followed by the nominal diameter and the pitch in mm.

Why did the flat thread fail to survive?

The description of the flat thread may sound unusual, but the thread profile described is actually very efficient. Because the flank angle is 0°, there is no radial pressure load. In addition, extremely little friction is generated when using a motion thread with a flat thread profile. As a result, the flat thread is even more efficient than the types of movement thread commonly used today. So what has led to the flat thread hardly being used today?

Although the profile of the flat thread is efficient, it is also very impractical. It is difficult to manufacture and requires considerably more effort to produce than other thread profiles. In addition, the rectangular shape of the flat thread makes it much more susceptible to damage and wear, as the sharp edges simply wear out more quickly.

As a result, the flat thread does not have a positive cost-benefit factor despite its high efficiency. It simply causes too many costs in production and due to the high wear and tear. Other thread profiles are much easier to produce and are just as suitable for use as movement threads.

These are the modern successors to the flat thread

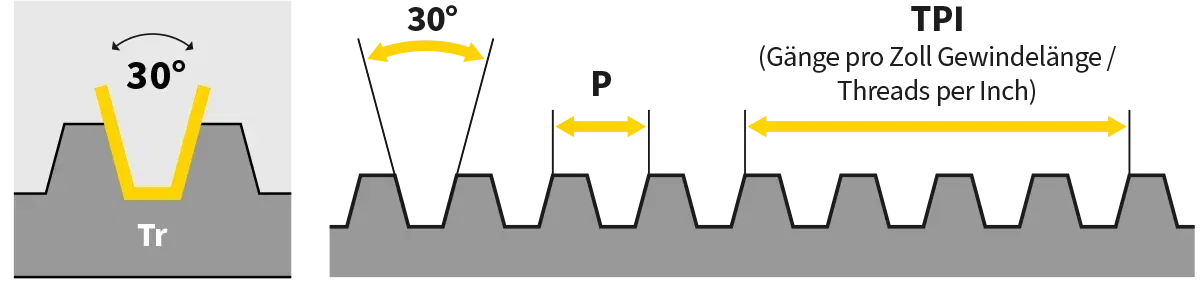

The trapezoidal thread is the official successor to the flat thread and an attempt to retain the advantages while reducing the disadvantages. In the profile of a trapezoidal thread, the historical model can still be guessed at. The only difference is that here, instead of squares, isosceles trapezoids are strung together. Just like the flat thread, the trapezoidal thread is used as a motion thread for lead screws and screw presses.

Two variants of the trapezoidal thread have established themselves as successors to the flat thread:

The metric trapezoidal thread is standardized according to DIN 103 and is the one you will encounter most frequently in this country. It has a flank angle of 30°, which is a significant difference compared to the flat thread. There is also a trapezoidal fine thread, which is also standardized according to DIN 103.

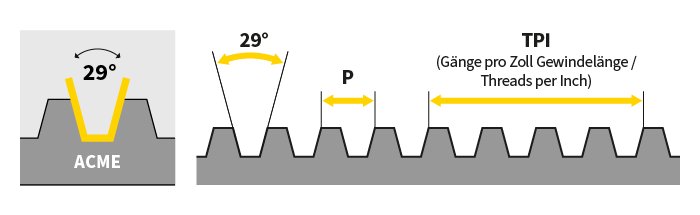

The American equivalent is the ACME trapezoidal thread. Although it is similar to the metric trapezoidal thread, with a flank angle of only 29° it also has a decisive difference. A variant of this successor to the flat thread is the STUB ACME thread with a smaller thread depth.

Do you still need a flat thread these days?

The question for you now is whether you need to memorize the facts and figures about the flat thread, or in other words: Do you still need the flat thread today? As a rule, the answer to this question is no. The flat thread has been replaced by very capable successors and is generally no longer used. However, you should not forget it completely. Because the extremely high efficiency of the flat thread is and remains a fact that cannot be argued away. And so there are still a few applications for which the flat thread is the best choice. In these cases, however, components with flat threads are manufactured at great expense as custom-made products.

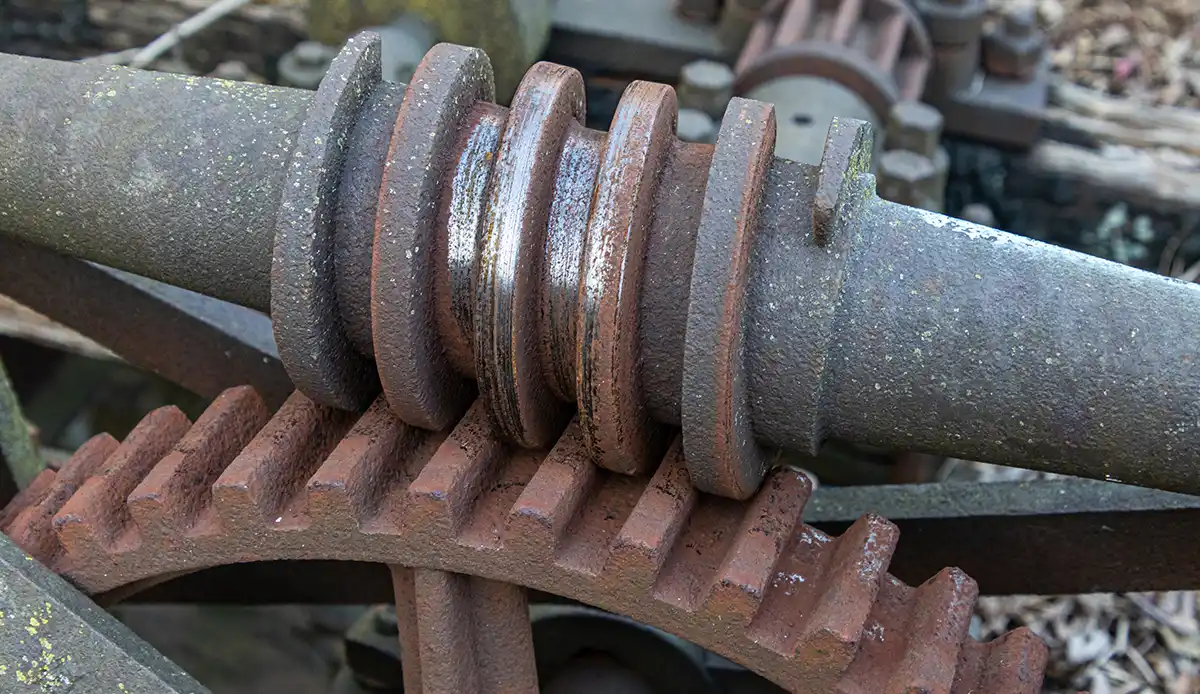

However, this does not apply to hobbyists who like to work with old components or repair historical equipment. Here it is quite possible that you will come across a flat thread. And there are also said to be one or two companies where machines are still in active use that should have been consigned to an industrial museum long ago. So here, too, it may well be possible to come across a threaded spindle with a flat thread. And if this ever happens to you, you now know exactly what you are dealing with!

Modern threads and high-precision threading tools are more your thing? Then we would like to recommend a visit to our online store. At BAER you will find everything you need for thread cutting. And our friendly customer service team will be happy to answer your questions and concerns.