Why Set Screws Only Work Thanks to Threads

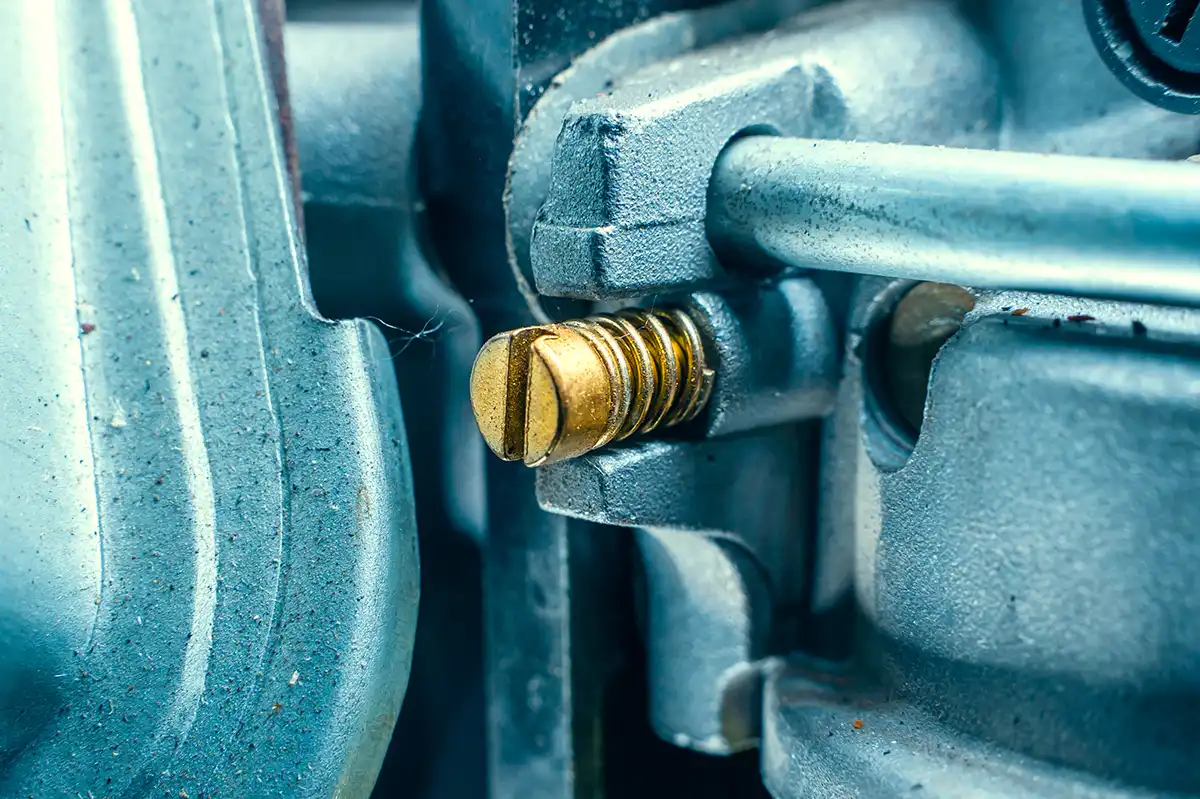

In craftsmanship, things can sometimes get a little rough—especially when it comes to threads. The motto is often: as long as it holds, it's good enough. But not every screw can handle such treatment, and there are even screws with a sensitive side that make them truly special. Set screws, for example.

If you approach set screws without finesse, you won’t get very far. Depending on the application, the purpose is indeed to form a screw connection between two components—but not just that. When you're turning the proverbial adjustment screw, you're aiming for precise fine-tuning, not simply a tight hold.

How does that work in practice? We took a closer look. First, we examine the pitch, which plays a particularly important role for set and adjustment screws. Then we explore a few common applications where these sensitive screws make a powerful impact.

Small Pitch: Fine Threads Make Adjustments Easier

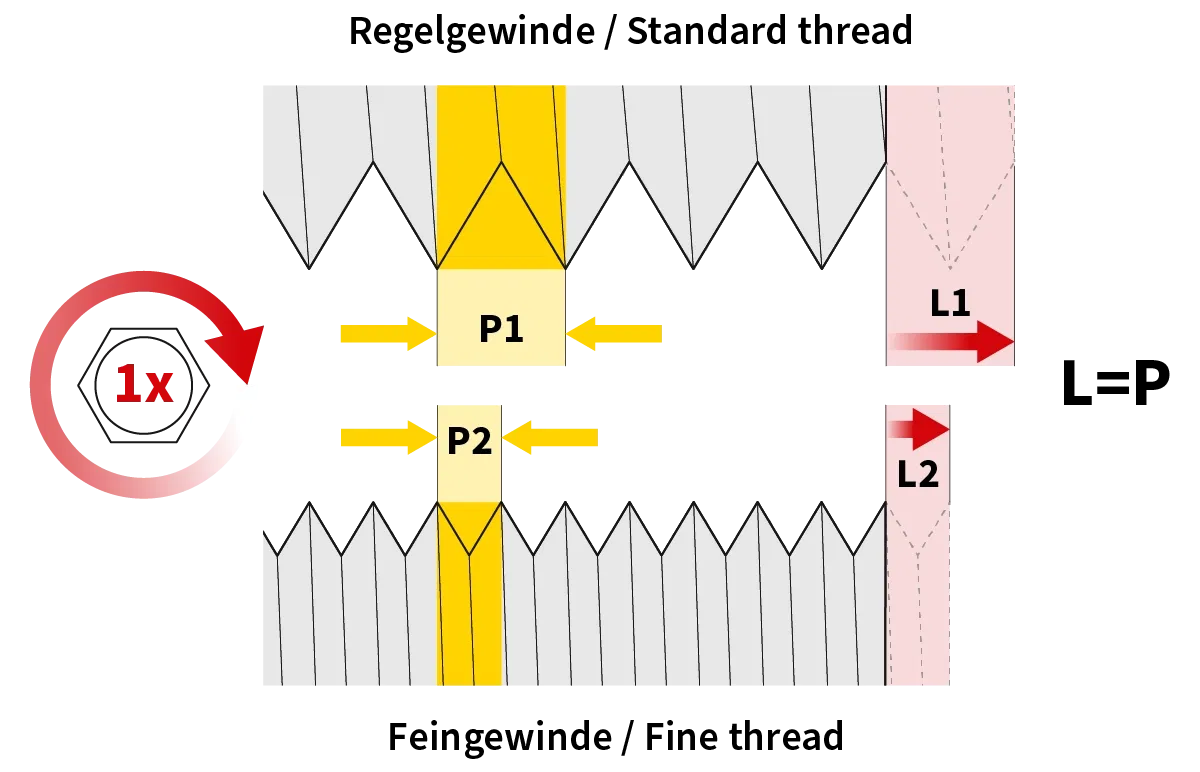

Not all, but many adjustment screws come with a fine thread, meaning they have a particularly small pitch. This is essential for making fine adjustments. Here's how it works:

The pitch also determines the distance a screw travels into a component per full turn. You can easily observe this yourself the next time you turn in a screw. Look closely and you'll notice that with each full turn, another thread disappears into the receiving thread.

This also means: the smaller the pitch, the shorter this distance—and the more precisely you can make adjustments by turning the screw. This allows for fine-tuning down to a fraction of a millimeter. That’s the advantage of the small dimensions of a fine thread.

On the flip side, the finer the thread, the longer it takes to fully screw in. Frequent and extensive adjustments can become time-consuming. In some cases, it may make sense to deliberately use a set screw with a standard thread—especially when precision isn’t the top priority. By choosing the right pitch, you can perfectly tailor the function of the set screw to its intended use.

Where Are Set Screws Used?

Set screws come in many different forms. Essentially, any screw used to adjust the spacing between components can be considered one. Let’s look at a few examples you’ve likely encountered before.

Screws for Adjusting Cabinet Doors

You’ve probably built a cabinet from a well-known Swedish furniture store at some point. The final step in this sometimes frustrating process is usually the adjustment of the cabinet doors. And how does that work? Exactly—with a set screw! The principle is particularly clear in the lateral adjustment screw.

While the other screws used to adjust the door vertically are typical mounting screws, the lateral adjustment works differently. This small screw is not for fastening but shifts the two parts of the hinge relative to each other, enabling fine adjustments.

Screws for Adjusting Sink Stoppers

Another example that might come in handy in the future is the set screw on your sink’s pop-up drain—you may not have even known it existed until now. Yet this variation of a set screw can save you a lot of trouble if the stopper isn’t sealing properly.

Adjusting the complex mechanism for operating the drain stopper can be a challenge even for professionals. Adjusting the stopper itself, however, is quite simple. Just turn the set screw and gradually achieve the perfect fit. So next time the water won't drain—or drains when it shouldn't—try adjusting the set screw on the drain.

Set Screws on Bicycles

Adjustment screws are also great for tailoring mechanical systems precisely to your needs. A good example of this is various components on bicycles. Both the braking system and gear shifting can be precisely optimized in this way.

On bikes, set screws often feature a lock ring or locknut to hold the screw in the correct position. To allow fine adjustments even on the go, they’re often designed for tool-free use. This concept is familiar from knurled screws, which have a textured grip area instead of a typical screw head, making them easy to turn by hand.

Don’t Confuse Them: Adjustment Screws in Drywall Construction

The term adjustment screw is also used for a special type of screw in wooden constructions. However, this is a completely different concept. These adjustment screws feature ridges directly beneath the head in addition to the thread. When attaching a slat or plank to a substructure, these ridges grip into the wood. By turning the screw counterclockwise, you can precisely adjust the distance between the slat and the surface.

Whether standard thread or fine thread – with us, you’ll find the right taps or dies for your set screws. As a manufacturer of threading tools with over 40 years of experience, we place great value on the quality of our products and the satisfaction of our customers. Try us out! If you have any questions or concerns, you can reach us anytime via email, phone, or our contact form.