BAER HSSE Combined Machine Tap M 6 x 1.0

BAER HSSE Combined Machine Tap M 6 x 1.0

The high-precision BAER combined machine tap makes it possible to produce core hole and through hole threads in one operation without changing tools. There is a twist drill part in front of the threaded part. Only through holes up to a maximum thread depth of 2 x diameter can be produced.

Our combination taps are powerful and reliable taps for efficient machining in one step with the machine. Combined machine taps are used especially in industrial production.

They can be used on machines with switchable speeds for drilling and thread cutting. The feed rate must be adapted to the respective operations of drilling or thread cutting.

Tapping chucks with pressure compensation cannot be used.

The high quality of the cobalt-alloyed HSSE steel we use ensures that our tools are extremely durable and robust. Due to special hardening processes and repeated tempering the hardness structure is very homogeneous, which forms the ideal basis for a genuine BAER screw taps. This increases the toughness and stability of the screw taps, allowing them to remain in use for longer.

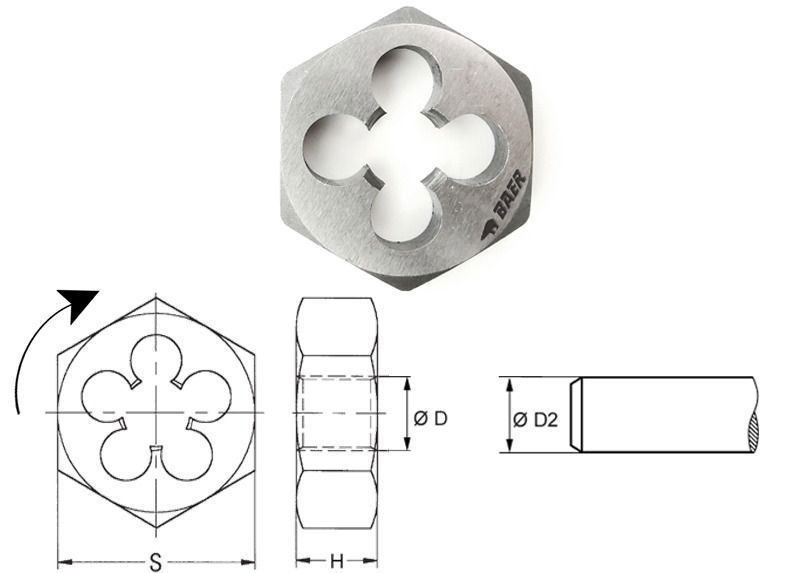

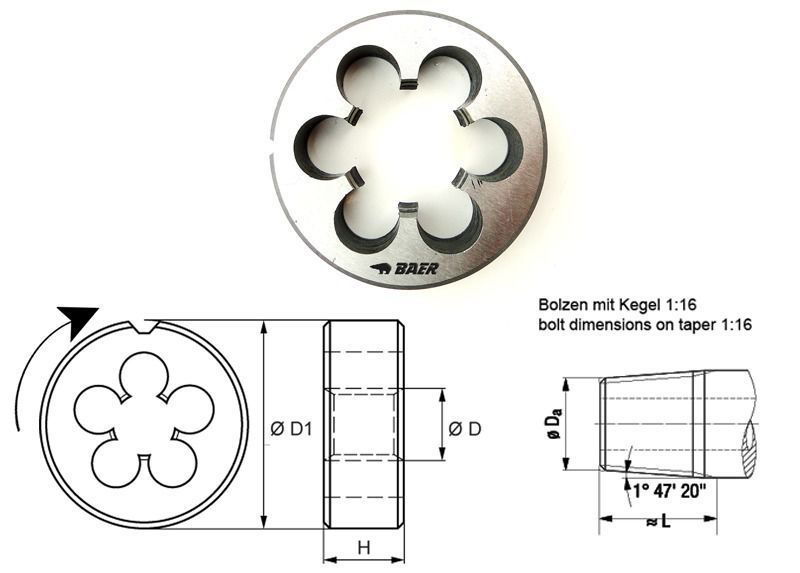

Dimensions

| Diameter |

6 |

|---|---|

| Nominal diameter in inches |

0,236 |

| Nominal diameter in mm |

6 |

| Pitch |

1,0 |

| Pitch in mm |

1 |

| Dimension |

M 6 x 1,0 |

Characteristics

| Product group |

Screw taps |

|---|---|

| Product type |

Machine taps |

| Thread standard |

M: Metric ISO standard thread according to DIN 13 |

| Tolerance |

ISO2/6H |

| Direction |

Right |

| Standard |

Factory standard |

| Tensile strength at room temperature |

up to 600 N/mm² |

| Material |

HSSE bright |

Applications

- Unalloyed and alloyed steel up to 600 N/mm²

- Malleable cast iron

- Ductile cast iron

- Copper

- Brass

- Aluminium

- Aluminium-magnesium alloy

- Zinc alloys

- Red brass

- Electron and zinc die casting

Technical drawing

| D1 |

M 6 x 1,0 |

|---|---|

| D2 |

5 mm |

| L1 |

80 mm |

| L2 |

22 mm |

| Diameter |

6 |

| Square |

4,9 mm |

Further information

- M - Metric ISO thread DIN 13

- Designations, geometries and definitions on taps

- Thread tolerances of the internal thread

- Internal thread and core hole dimensions

- Tap Chamfer forms

- Comparison inch-mm

- Surface treatments on tapping tools

- Cutting speeds and lubrication/cooling

- Information about tapping

- Material table