BAER HSSG Bit Tap M 4 x 0.7

BAER HSSG Bit Tap M 4 x 0.7

BAER Bit taps are designed for thread cutting with cordless screw drivers and hand drilling machines with clockwise and anti-clockwise rotation. However, they are also suitable for thread cutting by hand and on stationary drilling machines. Your cordless screw driver should have a power of at least 7.5 volts. Make sure that the tool axis and hole axis are exactly aligned and use a suitable cutting oil. For thread cutting with cordless screw drivers and hand drillig machines, we recommend the lowest speed settings (0 - 450 rpm) and maximum torque settings.

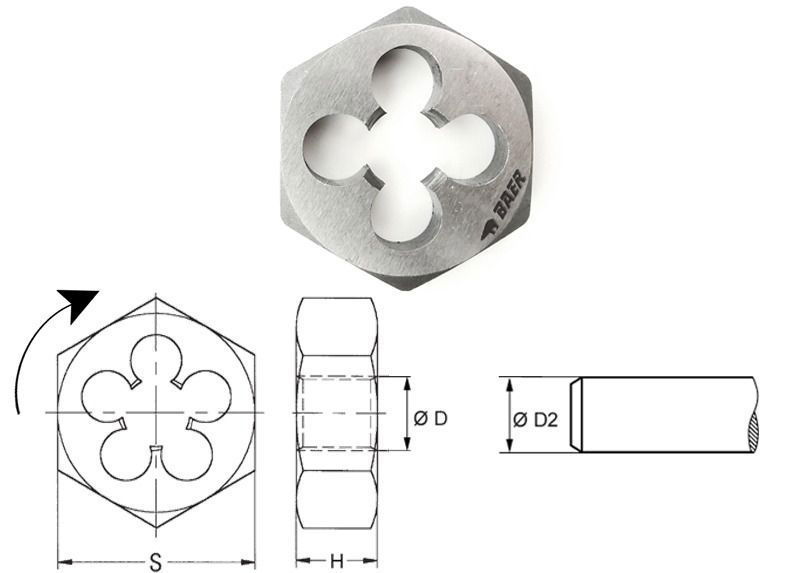

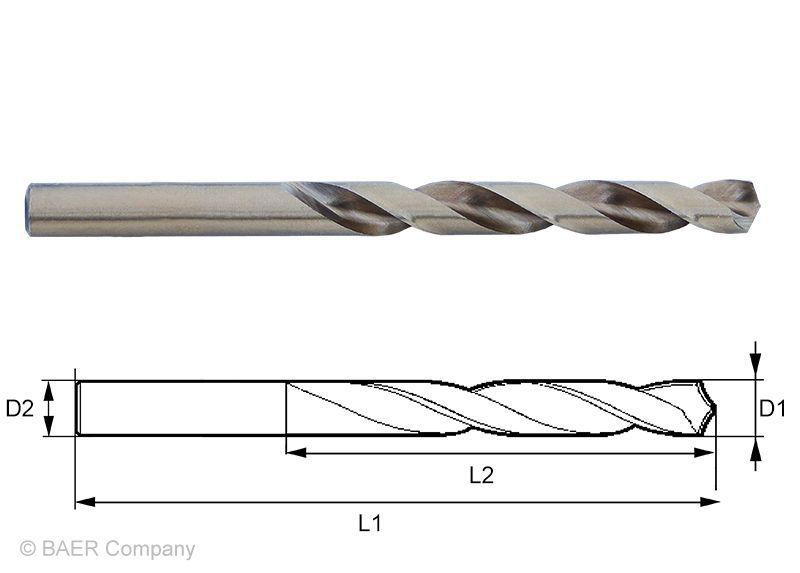

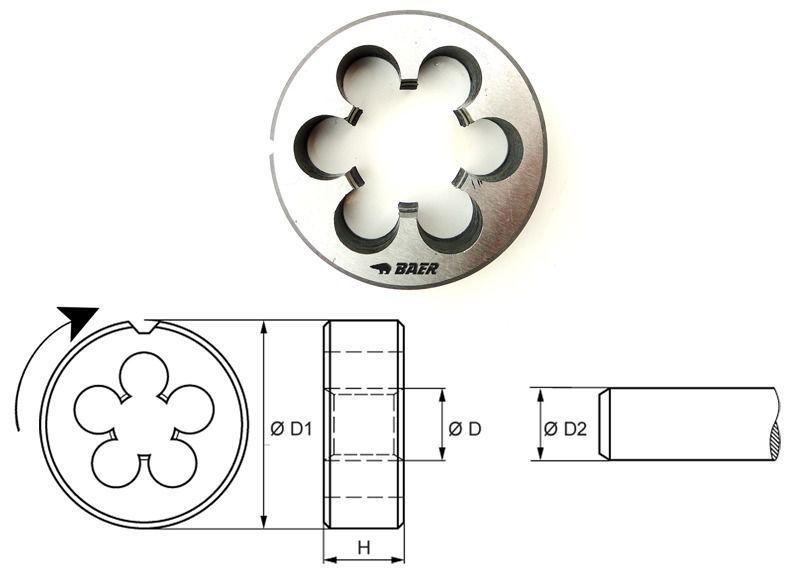

Dimensions

| Diameter |

4 |

|---|---|

| Nominal diameter in inches |

0,157 |

| Nominal diameter in mm |

4 |

| Pitch |

0,7 |

| Pitch in mm |

0,7 |

| Dimension |

M 4 x 0,7 |

Characteristics

| Product group |

Screw taps |

|---|---|

| Product type |

Bit taps/Combined bit taps |

| Thread standard |

M: Metric ISO standard thread according to DIN 13 |

| Tolerance |

ISO2/6H |

| Direction |

Right |

| Standard |

Factory standard |

| Tensile strength at room temperature |

up to 900 N/mm² | 27.1 HRC |

| Material |

HSSG bright |

3.3 mm

Through hole and blind hole up to 2 x D

Form D straight fluted

3.5-5 threads

Rarely occurs. Chips remain in flutes.

External cooling and lubrication

HSSG bright

up to 900 N/mm² | 27.1 HRC

ISO2/6H

Applications

Steel, non-ferrous metals and plastics up to 600 N/mm² tensile strength

Examples of applications

- Bicycle thread M4 for brake circuit

Technical drawing

| D1 |

M 4 x 0,7 |

|---|---|

| L1 |

35 mm |

| L2 |

12 mm |

| Diameter |

4 |

Further information

- M - Metric ISO thread DIN 13

- Designations, geometries and definitions on taps

- Thread tolerances of the internal thread

- Internal thread and core hole dimensions

- Tap Chamfer forms

- Comparison inch-mm

- Surface treatments on tapping tools

- Cutting speeds and lubrication/cooling

- Information about tapping

- Material table