-

Taps & Dies

-

Thread standards

- M - metric regular thread

- MF - metric fine thread

- G (BSP) - pipe thread

- UNC - American coarse thread

- UNF - American fine thread

- UNEF - amer. Extra fine thread

- UN - amer. with special pitch

- UNS - amer. with special pitch

- BSW - british coarse thread

- BSF - British fine thread

- Tr - trapezoidal thread

- Rd - knuckle thread

- NPT - amer. taper pipe thread

- NPTF - amer. taper pipe thread

- NPS - amer. cyl. pipe thread

- Rc (BSPT) - taper pipe thread

- Rp (BSPP) - cyl. pipe thread

- Vg - valve thread

- BA - brit. assn. Thread

- BSB - BSC - brit. std. thread

- W - taper gas cylinder valves

- Electrical and cable thread

- Bicycle and pedal thread

- Photo and C-Mount Thread

- Mini and nano threads (< 2mm)

- PG - steel conduit thread

- S - buttress thread

- RMS - microscope thread

- MJ, UNJC, UNJF - Aviation

- STI thread (thread inserts)

- Special thread

- Operating tools

- Lubricant

- Thread restoration tools

- Countersink

- Step drills

- Thread gauges

-

Thread standards

- Twist drill bits

- Drill chucks

- BaerCoil/BaerFix

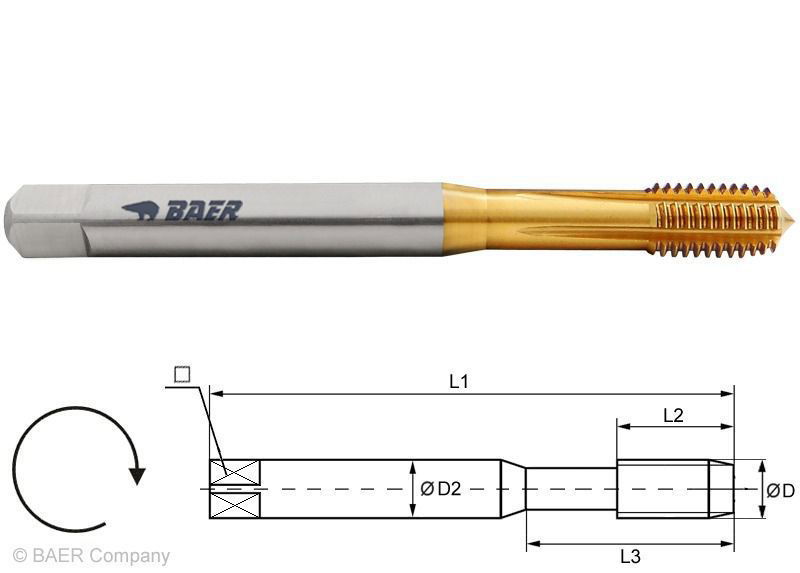

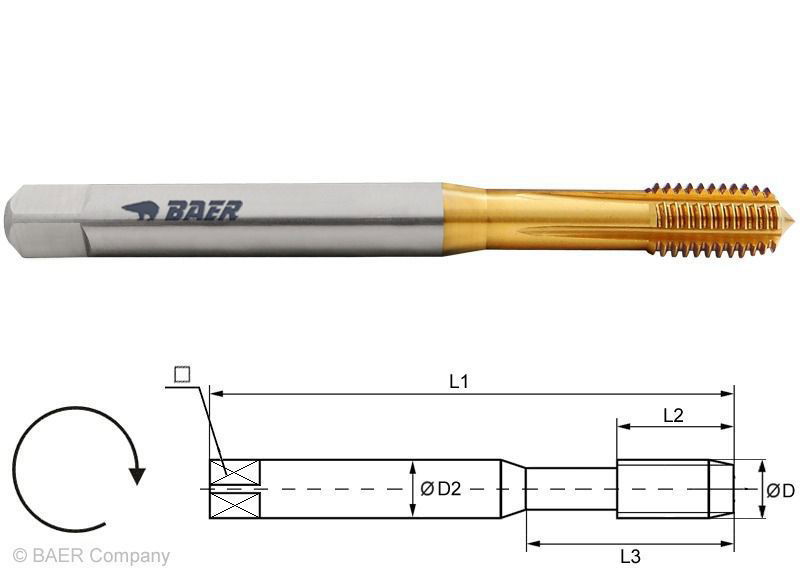

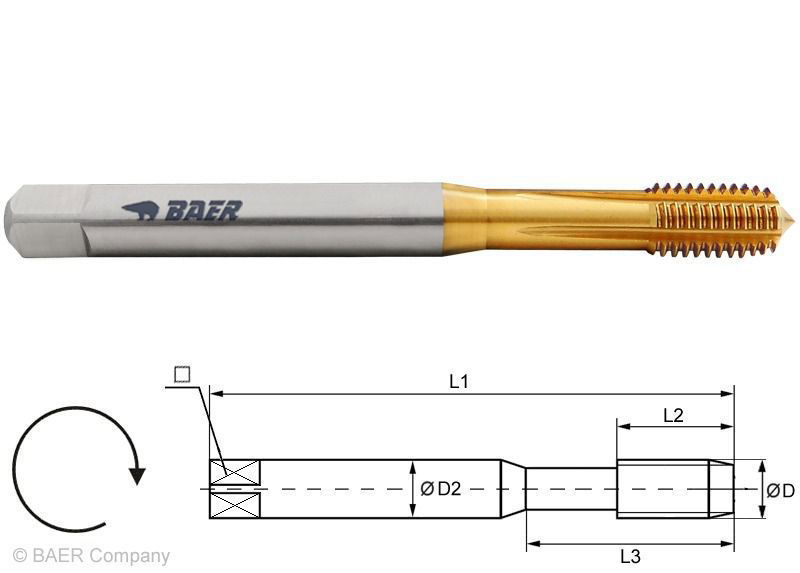

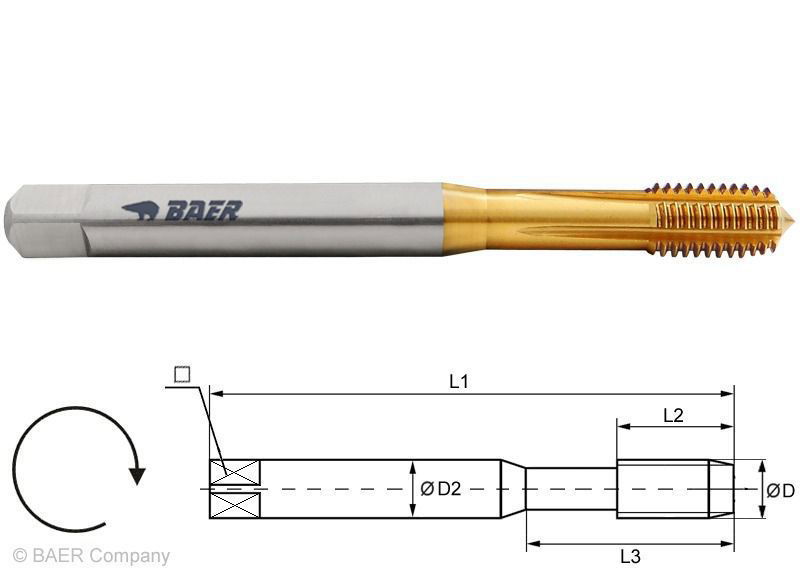

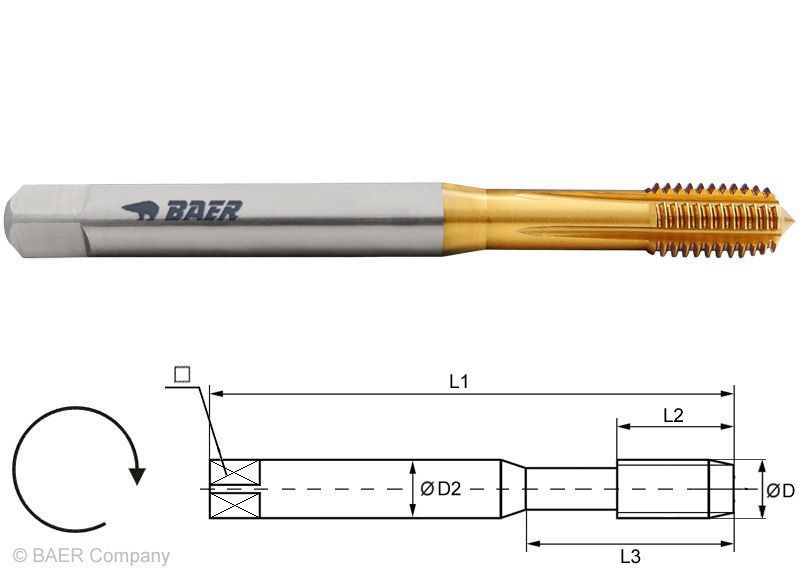

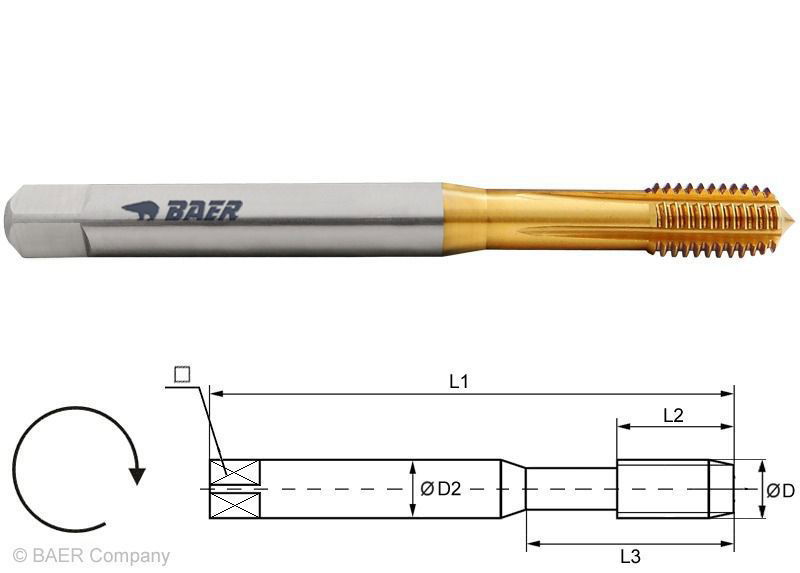

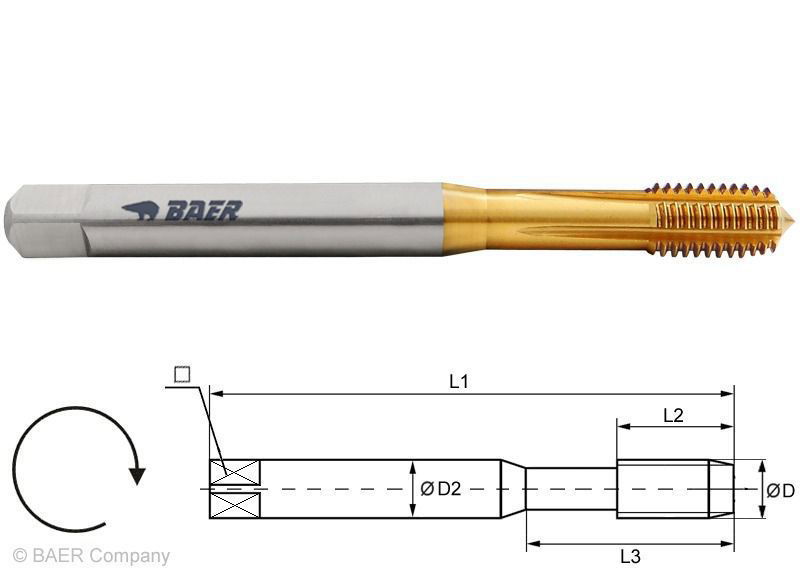

Forming taps from BAER - Chipless thread production

Toolfinder

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

In stock

Express shipping available

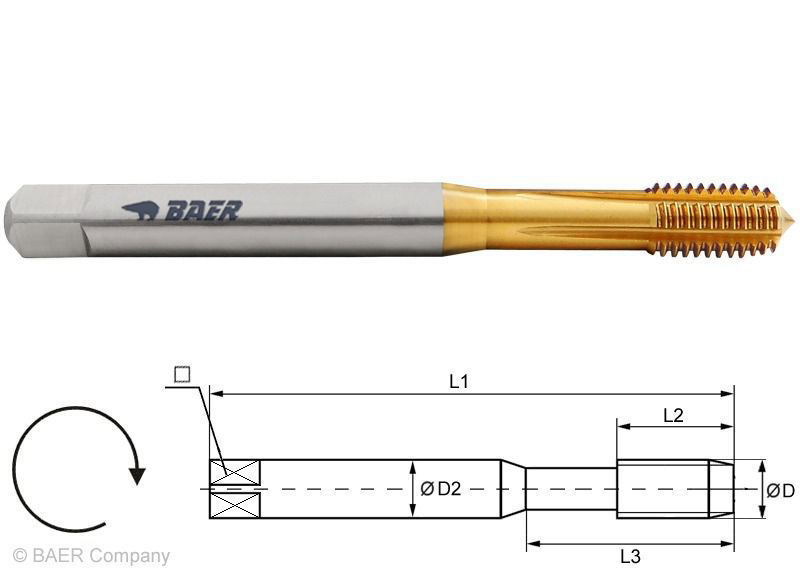

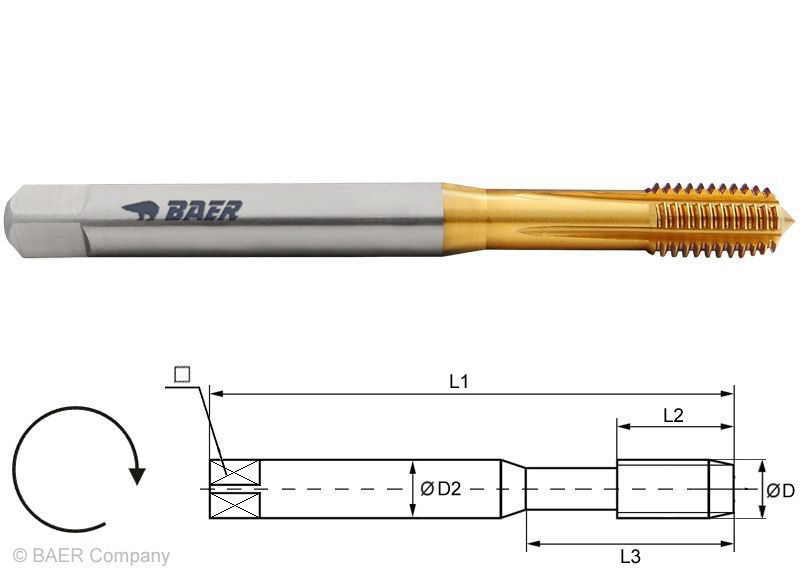

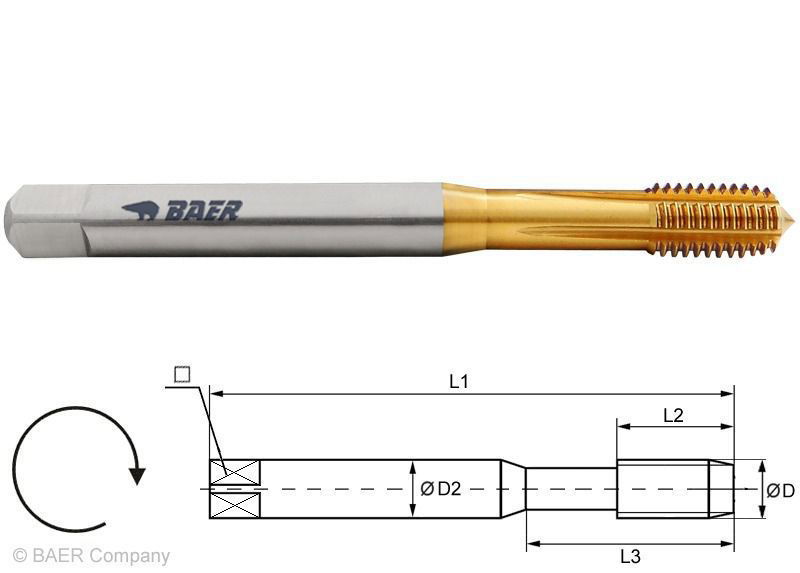

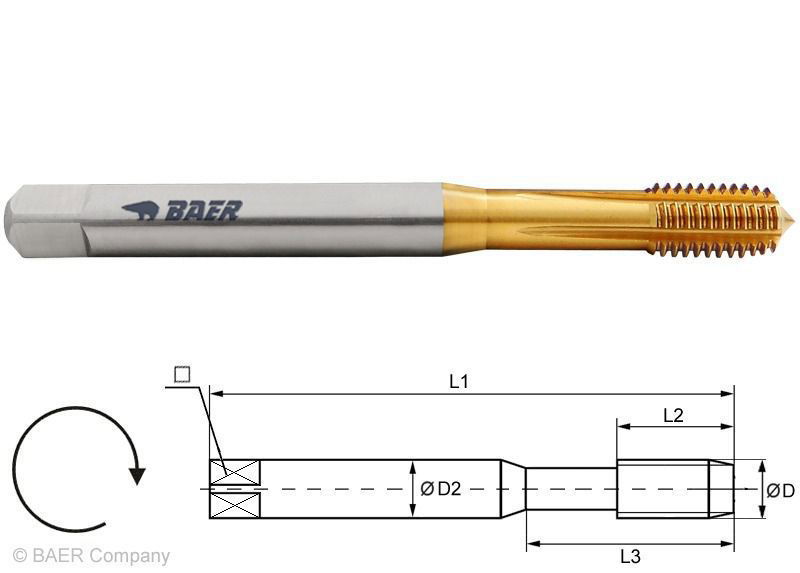

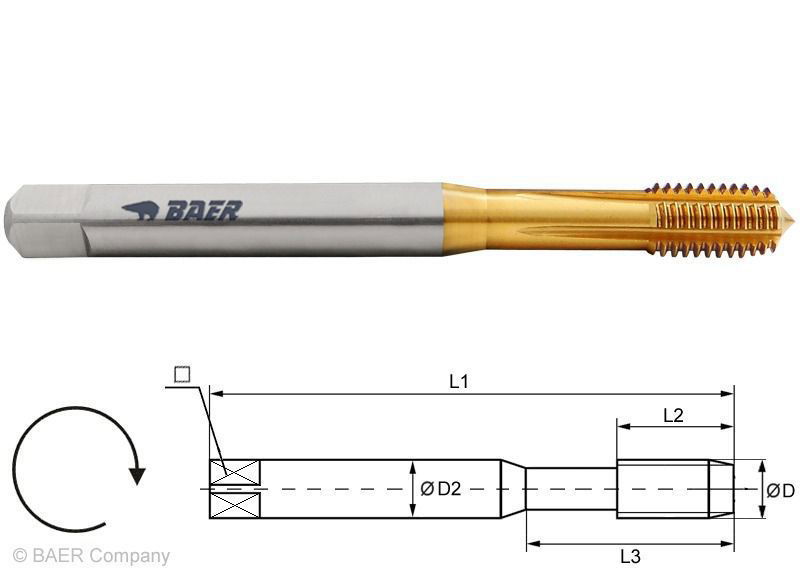

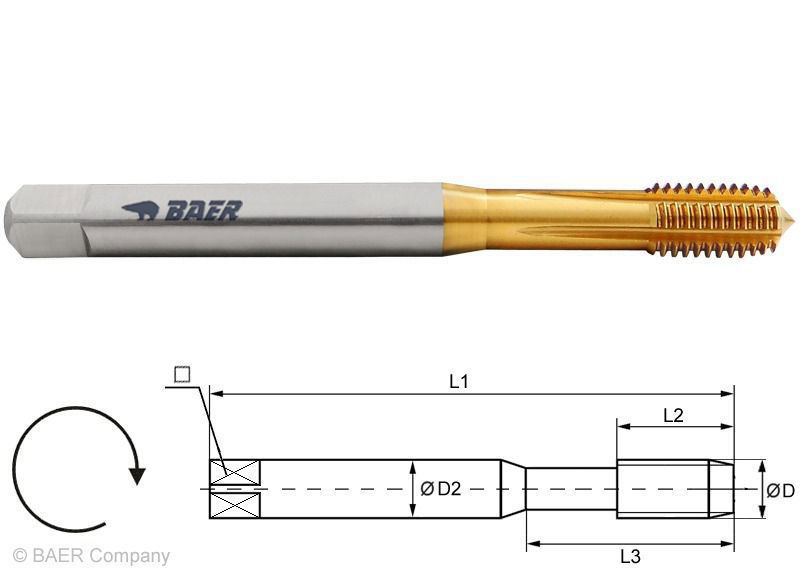

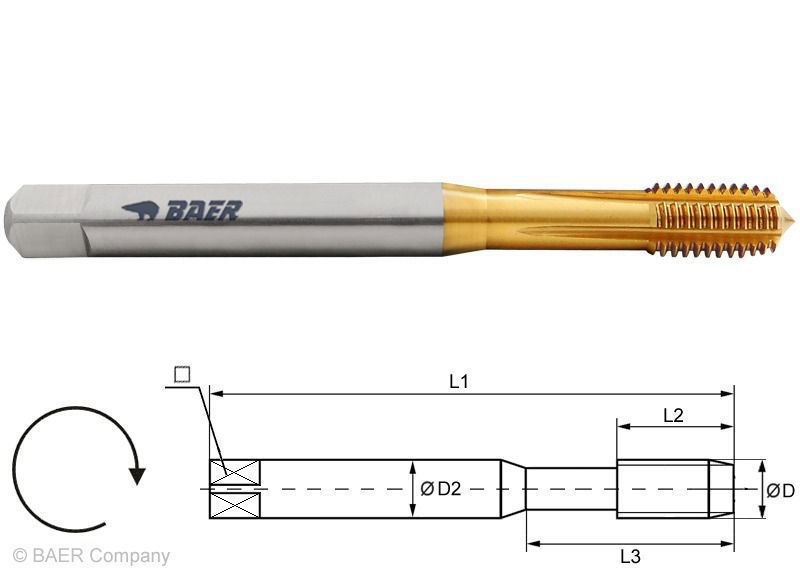

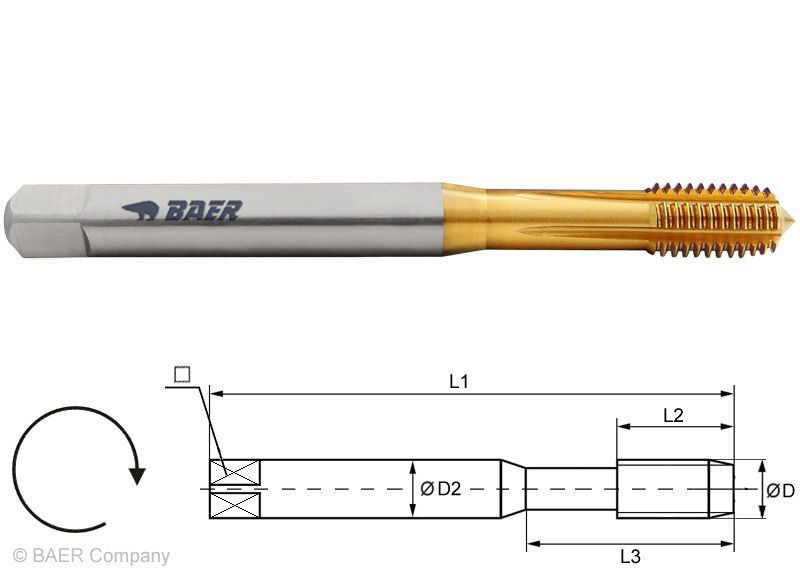

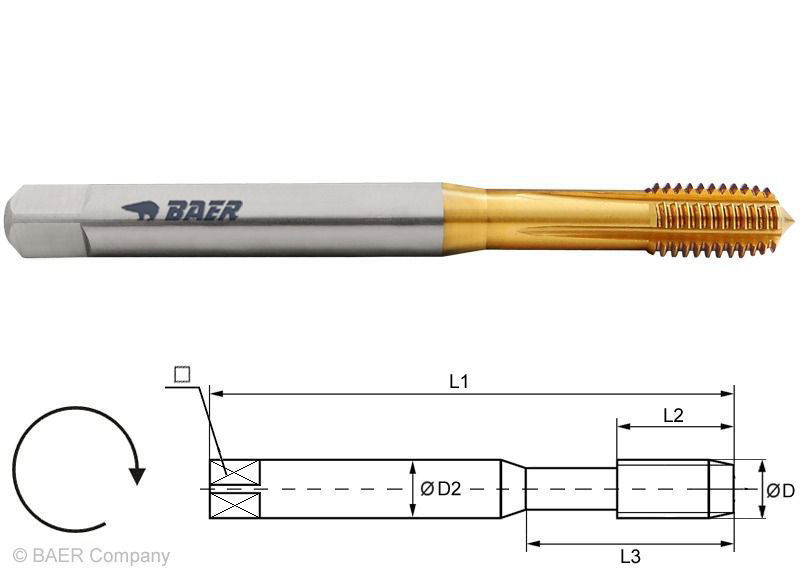

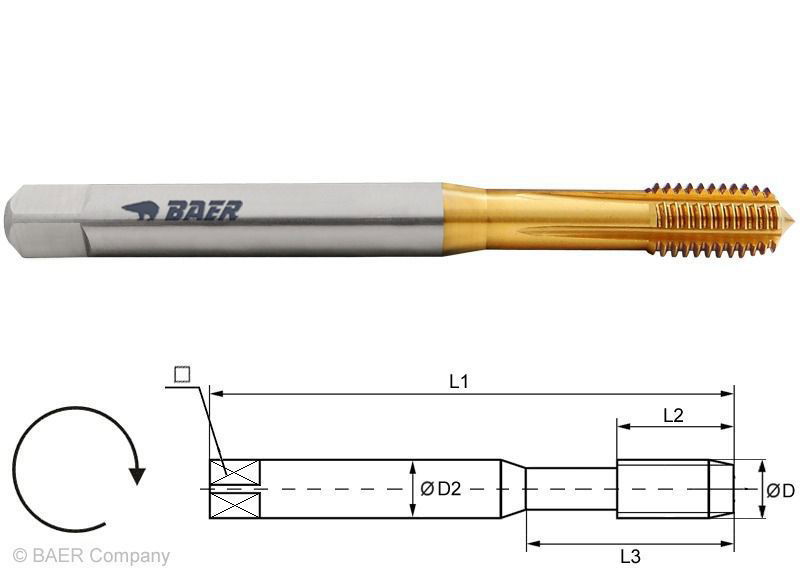

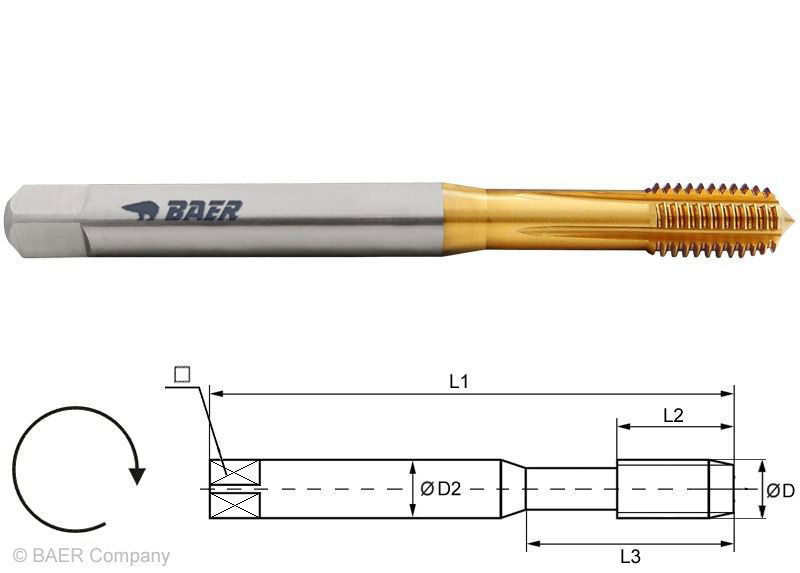

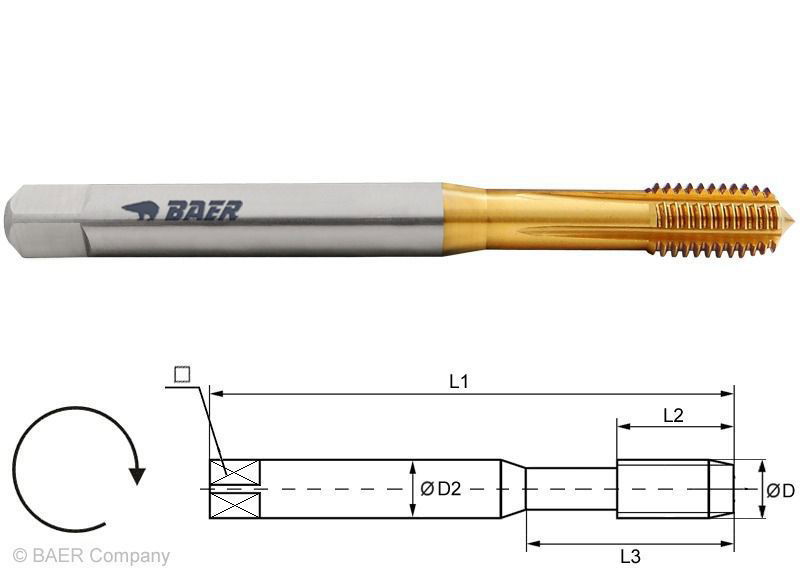

Forming tap - Producing threads without chips

The thread cutting is not the only way to produce a thread. Depending on the material used and the field of application, the suitable working tool may be the forming tap, also known as fluteless tap. You can use it to produce particularly strong internal thread in a chipless process. But before you buy a forming tap, you should familiarise yourself with these tools. Even though forming taps and screw taps are similar, they are not the same. Although Machine taps are similar, they are two completely different tools with different processes.

Forming tap vs. screw tap - What are the differences?

At first glance, the way forming taps and screw taps work seems similar: the core hole is prepared, the tool is screwed in and the desired thread remains. But appearances are deceptive, because at the molecular level, these are two very different processes. Whereas with thread cutting the fibres in the material are cut, with thread forming they remain intact and are merely compressed. This ensures a particularly high material strength and a smooth surface.

The two tools also differ visually. Since it is a non-cutting process, the forming tap does not need a flutes through which chips can pass out of the hole. However, some models have oil grooves that serve to better distribute lubricant. In addition, the profile of the tap is polygonal instead of round. Incidentally, the finished threads also differ in appearance. This is because characteristic small forming pockets are formed at the tips of the thread produced by the forming tap.

How does a forming tap work?

A forming tap creates an internal thread by deforming material instead of removing it. This process is also called cold forming because it takes place below the recrystallisation temperature of the material. This is important because recrystallisation removes irregularities in the crystal lattice of a metal (also known as lattice defects), which reduces the strength of the material. Cold forming, on the other hand, has the opposite effect - it increases the material's strength. And this is ultimately a decisive factor for the stability of a thread.

Before you can work with the forming tap, you have to drill a core hole. Compared to the thread cutting, the dimensions of the holes are larger because the material springs back somewhat. This fact must be compensated for by a larger diameter. You can calculate this using the formula Dk=D - (0.5 x P) + 0.05, where Dk is the core hole diameter, D is the thread diameter and P is the pitch. Alternatively, simply read the correct value from a table. Please note, however, that these values are intended only as a guide. Depending on the material properties, the actual dimensions required may differ.

Once you have determined the correct diameter and pre-drilled the core hole, the forming tap is used. To create the thread, turn the fluteless tap into the prepared core hole. The starting cone on the tip of the tool facilitates this process. The thread tips press into the material, which is thereby pressed into the thread gaps. This displacement and simultaneous compression of the material forms the thread. Caution, high frictional forces can arise here! You must therefore make sure that there is sufficient lubrication. Finally, set the machine to counterclockwise rotation and turn the forming tap out of the finished thread.

When is the forming tap used? Thread forming is the fastest way to make internal threads

Due to the special characteristics of the process, the forming tap's field of application is limited. So before you buy a forming tap, you should think about whether it is the right tool for your application.

First of all, you need to consider the material you want to work with. Cold forming is not possible with every material. Light metals, pure titanium, non-ferrous metals and steels up to approx. 1200 N/mm2 are well suited for it. The material properties also set limits on the maximum possible pitch for forming taps; more than 3 mm is hardly achievable.

Since the necessary torques cannot be achieved with manual use, there are also only machine taps or hand taps available. This means that the forming tap tends not to be a tool for do-it-yourselfers or businesses where thread production is not one of the everyday tasks. The process also requires some skill and experience, as the tolerance pre-drill diameter is very narrow and re-tapping is not possible. Other methods are therefore recommended for starting out in the field of thread production.

If the prerequisites are met, however, you can use a forming tap to produce very stable threads of high strength that also have a particularly high surface quality. When used correctly, you can neither cut the thread with a machine tap, nor do pitch or flank angle errors occur. In addition, you achieve a significantly higher cutting speed than with a screw tap.

The chipless nature of the process also has advantages. Where there are no chips, there are also no problems with disposal or the cleaning of deep drill holes. The tool itself is also subjected to less stress due to the non-cutting process, which leads to long tool life and less risk of breakage.

Forming taps from the BAER range

In our online shop you will find forming taps in many different sizes and thread standards. Forming taps without oil grooves are suitable for working with thin and/or soft materials that do not pose any particular challenges to the lubricant film. Forming taps with oil grooves, on the other hand, ensure a particularly even distribution of the lubricant and an unbroken lubricant film and are used for larger thread depths.

In addition to the standard 6HX, our range also includes forming taps of other tolerance classes. The models of tolerance class 6GX are suitable for threaded connections with wide fitting. And our forming tap of the tolerance class 7GX preventively calculate the distortion by heat treatment. This way you can be sure that your thread really has the desired diameter in the end.

At BAER Tools it is important to us to give you exactly the tool that best supports you in your work. This includes not only a lot of care in the production and in the selection of high-quality raw material, but also comprehensive advice before and after the purchase. If you would like to buy a forming tap but still have questions, please feel free to contact us at any time in confidence via our contact form at customer service. We are happy to help!

Do you have any questions? We have the answers!

You'll quickly find the right answers in our FAQ - take a look!