-

Taps & Dies

-

Thread standards

- M - metric regular thread

- MF - metric fine thread

- G (BSP) - pipe thread

- UNC - American coarse thread

- UNF - American fine thread

- UNEF - amer. Extra fine thread

- UN - amer. with special pitch

- UNS - amer. with special pitch

- BSW - british coarse thread

- BSF - British fine thread

- Tr - trapezoidal thread

- Rd - knuckle thread

- NPT - amer. taper pipe thread

- NPTF - amer. taper pipe thread

- NPS - amer. cyl. pipe thread

- Rc (BSPT) - taper pipe thread

- Rp (BSPP) - cyl. pipe thread

- Vg - valve thread

- BA - brit. assn. Thread

- BSB - BSC - brit. std. thread

- W - taper gas cylinder valves

- Electrical and cable thread

- Bicycle and pedal thread

- Photo and C-Mount Thread

- Mini and nano threads (< 2mm)

- PG - steel conduit thread

- S - buttress thread

- RMS - microscope thread

- MJ, UNJC, UNJF - Aviation

- STI thread (thread inserts)

- Special thread

- Operating tools

- Lubricant

- Thread restoration tools

- Countersink

- Step drills

-

Thread gauges

- M - metric regular thread

- MF - metric fine thread

- G (BSP) - pipe thread

- UNC - American coarse thread

- UNF - American fine thread

- UNEF - amer. Extra fine thread

- Tr - trapezoidal thread

- NPT - amer. keg. pipe thread

- NPTF - amer. keg. pipe thread

- Rc (BSPT) - keg. pipe thread

- Rp (BSPP) - cyl. pipe thread

- PG - steel conduit thread

- STI thread (thread inserts)

-

Thread standards

- Twist drill bits

- Drill chucks

- BaerCoil/BaerFix

Thread gauges for metric fine threads according to DIN 13

Toolfinder

How do you actually know that your metric fine thread really corresponds to the standard? Of course, you rely on the information on your tool. In everyday life, this is often sufficient. But there are always situations where precision is particularly important when cutting a metric fine thread. You should therefore know how you can determine whether the fine thread is actually within the tolerances specified in the standard. Thread gauges for a metric ISO fine pitch thread are a reliable aid here and are also easy to use. As no measured value is determined when gauging a metric fine thread, but only a decision is made between "good" or "reject", the process is almost completely protected against measurement and transmission errors.

For these reasons, you should gauge a metric fine thread

If you have a screw tap for your fine thread in metric form, labelled MF 3 x 0.35, then you will also produce a thread with a diameter of 3 mm and a pitch of 0.35 mm, right? Unfortunately, this is not quite as crystal clear as it seems at first glance. To ensure that the tolerances are adhered to, you should regularly gauge your thread. There are a few good reasons for this.

Threading tools for metric fine threads can change their properties

Over a long period of constant use, the properties of your screw tap or the thread cutting die for the metric fine thread can change. Wear and dirt are the first suspects when it comes to the question of whether a tool is still cutting true to gauge threads. That's why you should check the gauge at regular intervals.

Incidentally, it is also worth gauging a metric fine thread when using new tools for the first time. Especially if your new acquisition is an inexpensive tool from an unknown manufacturer.

Your metric fine thread should work perfectly

Precision is particularly important if you want to produce a metric fine thread. If the Dimensions are not within the specified tolerances, the screw and nut may not fit together perfectly. Even the smallest deviations are enough to impair the interaction of the threads.

If your metric fine pitch thread does not comply with the standard, this can have legal consequences

If you have cut a metric fine pitch thread out of tolerances, this can also have legal consequences. This is the case if you supply workpieces to customers with such a defective thread. Thread gauges are standardised according to DIN ISO 1502 and provide the decisive verdict in cases of dispute. To ensure that you are always on the safe side legally, regularly check metric fine threads for gauge accuracy.

Gauge a metric fine pitch thread with these tools

With the right holding tool, it is very easy to check the gauge accuracy of a fine pitch thread. To test both external and internal thread you need two different types of thread gauges.

Thread plug gauges for a metric fine thread

Thread plug gauges check the internal thread for gauge accuracy. The pitch diameter and deviations in the profile of the thread are checked. The GO plug gauge checks whether a metric fine thread complies with the specified minimum dimension. The NO-GO plug gauge checks the maximum dimension at the other end of the scale.

Up to a thread diameter of 40 mm, these two tools are mounted on a common handle. In this case, we speak of a thread limit plug gauge. Above 40 mm, the GO and NO-GO plug gauges are two different tools, each with its own handle.

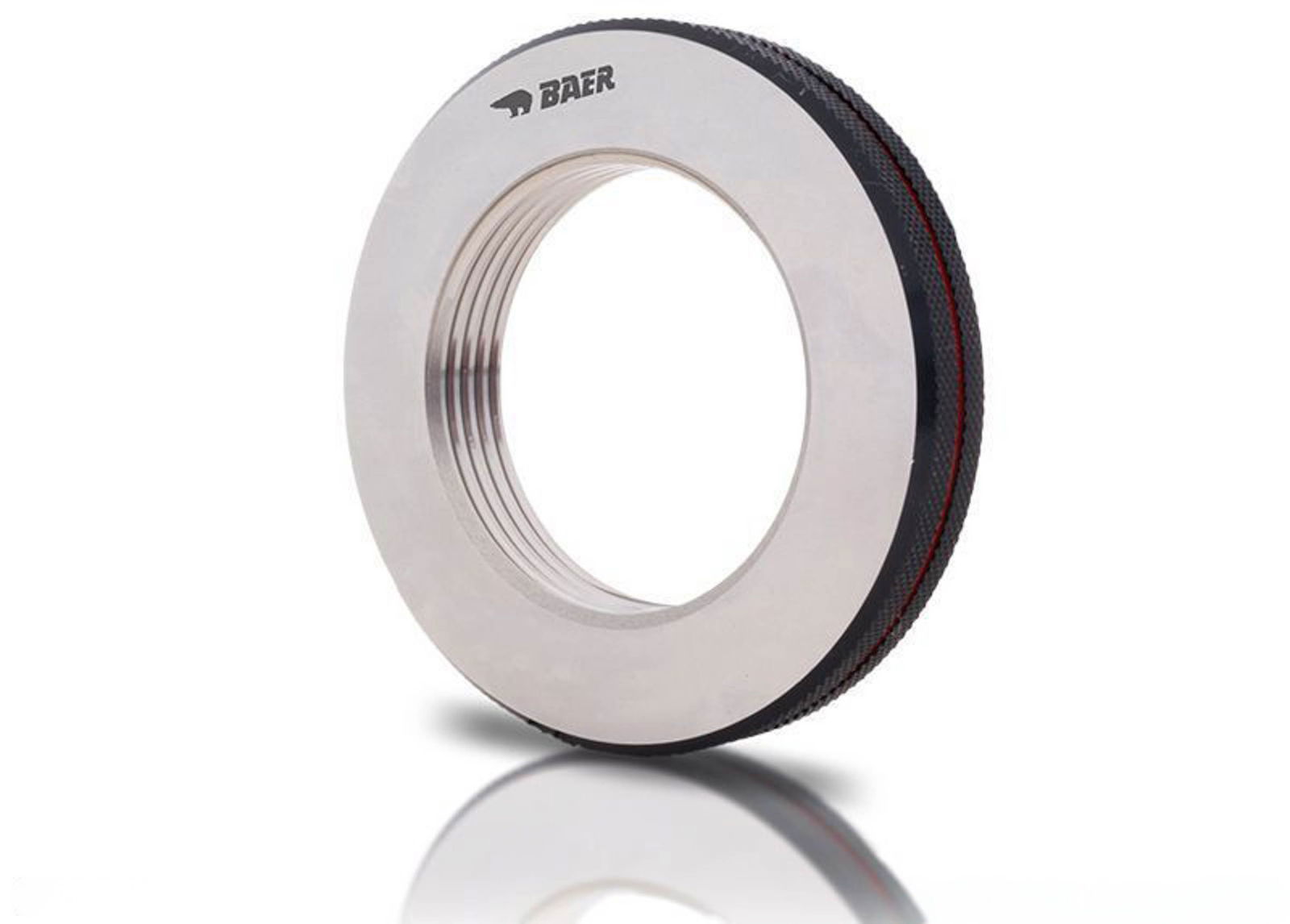

Ring gauges for a metric fine thread

Ring gauges work in the same way as plug gauges. Here, too, there is a GO ring gauge and a NO-GO ring gauge. Unlike plug gauges, however, these are always two separate tools, regardless of the thread size to be tested.

You must pay attention to this when gauging a metric fine thread

It is not difficult to correctly gauge a fine thread. You do not need to determine a numerical value and compare it with a table. The thread gauge takes care of the entire testing process for you. Turn plug gauges into a internal thread. The GO plug gauge must be able to be screwed in completely, the NO-GO plug gauge must not be able to be screwed in more than two turns. Screw the ring gauges for a metric fine thread onto an external thread. The following also applies here: The GO ring gauge must be able to be screwed on completely, whereas the NO-GO ring gauge should not be screwed on more than two turns.

The general conditions must be right so that the gauge accuracy can be checked correctly. A fine thread to be tested must be dry, clean and free of lubricants. In addition, you should always carry out the test at room temperature, i.e. at around 20 degrees. This will prevent the material from expanding or contracting due to temperature influences. Furthermore, you should not apply any force when checking a metric fine pitch thread for gauge accuracy. Do not attempt to force a thread ring gauge or thread plug gauge into or onto a metric fine pitch thread. If you observe these points, you can rely on the test result obtained.

Thread gauges for a metric fine thread in the BAER online shop

In the BAER online shop - the professional screw tap manufacturer - you will find thread plug gauges and thread ring gauges to check your metric fine thread easily and reliably. We cover the entire range with sizes up to MF 110 x 4.0. We are guaranteed to have the right thread gauge for your metric ISO fine thread in our range.

When purchasing a thread gauge, you can also order a calibration directly from our shop. This provides you with absolute certainty about the reliability of the thread gauge and you also receive a certificate of the result.

If you have any questions about gauging a fine thread and especially a metric fine thread, our customer service is always available for you.

Do you have any questions? We have the answers!

You'll quickly find the right answers in our FAQ - take a look!