BaerCoil HSSG Short Machine Tap Harley 7/16 x 16 STI (oversized for wire thread inserts)

In stock

Express shipping available

BaerCoil HSSG Short Machine Tap Harley 7/16 x 16 STI (oversized for wire thread inserts)

BaerCoil® screw tap are mainly used for thread repair or thread reinforcement in connection with wire thread inserts. With this BaerCoil® short machine tap, a finished thread with oversize can be cut in one operation as a holding thread for wire thread inserts of dimension Harley 7/16 x 16. Precise internal thread can thus be cut time-savingly by hand or semi-professionally by machine.

The receiving thread for Harley 7/16 x 16 thread inserts is also called STI thread (screw thread insert) or STI thread (in English Screw Thread Insert) and has an oversize so that the normal Harley 7/16 x 16 starting thread is restored after installation of the thread insert.

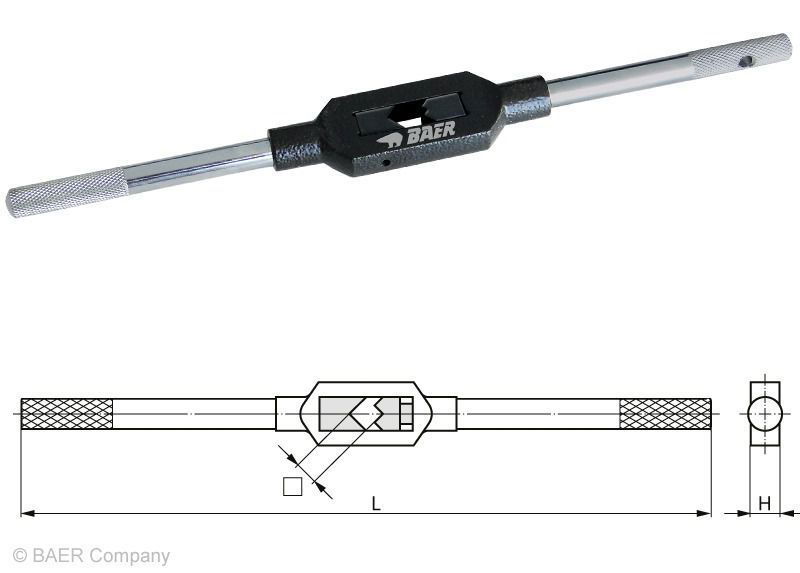

Compared to the machine tap, the short machine tap has a short shank. This allows internal thread to be cut by hand without jamming and operated with tap wrenches, ratchets or other holding tools with square drive. The thread can be cut in a pre-drilled core hole. Pre-machining with a taper tap (No. 1) or intermediate tap (No. 2) is not necessary.

With the short chamfer and the straight flutes, the chip is mainly absorbed by the flutes and is not removed during cutting. To prevent the chips from sticking, it is recommended to remove the chips from the grooves with a brush, compressed air or similar after each thread cutting. This form of gating makes the screw tap reliable and universally applicable for both through holes and blind holes.

Dimensions

| Diameter |

7/16 |

|---|---|

| Nominal diameter in inches |

0,52 |

| Nominal diameter in mm |

13,2 |

| Pitch |

16 |

| Pitch in mm |

1,587 |

| Dimension |

Harley 7/16 x 16 EG/STI |

| Square |

8,2 mm |

Characteristics

| Product group |

Screw taps Wire thread inserts - Taps |

|---|---|

| Product type |

BaerCoil screw taps |

| Thread standard |

Harley EG/STI: American Unified National Harley Davidson Thread for wire thread inserts |

| Direction |

Right |

| Standard |

Factory standard |

| Tensile strength at room temperature |

up to 800 N/mm² | 22.2 HRC |

| Material |

HSSG bright |

11.5 mm

Through hole and blind hole up to 2 x D

Form D straight fluted

3.5-5 threads

Rarely occurs. Chips remain in flutes.

External cooling and lubrication

HSSG bright

up to 800 N/mm² | 22.2 HRC

Applications

All normal uses for thread repair and for thread reinforcement of through-hole and blind-hole threads.

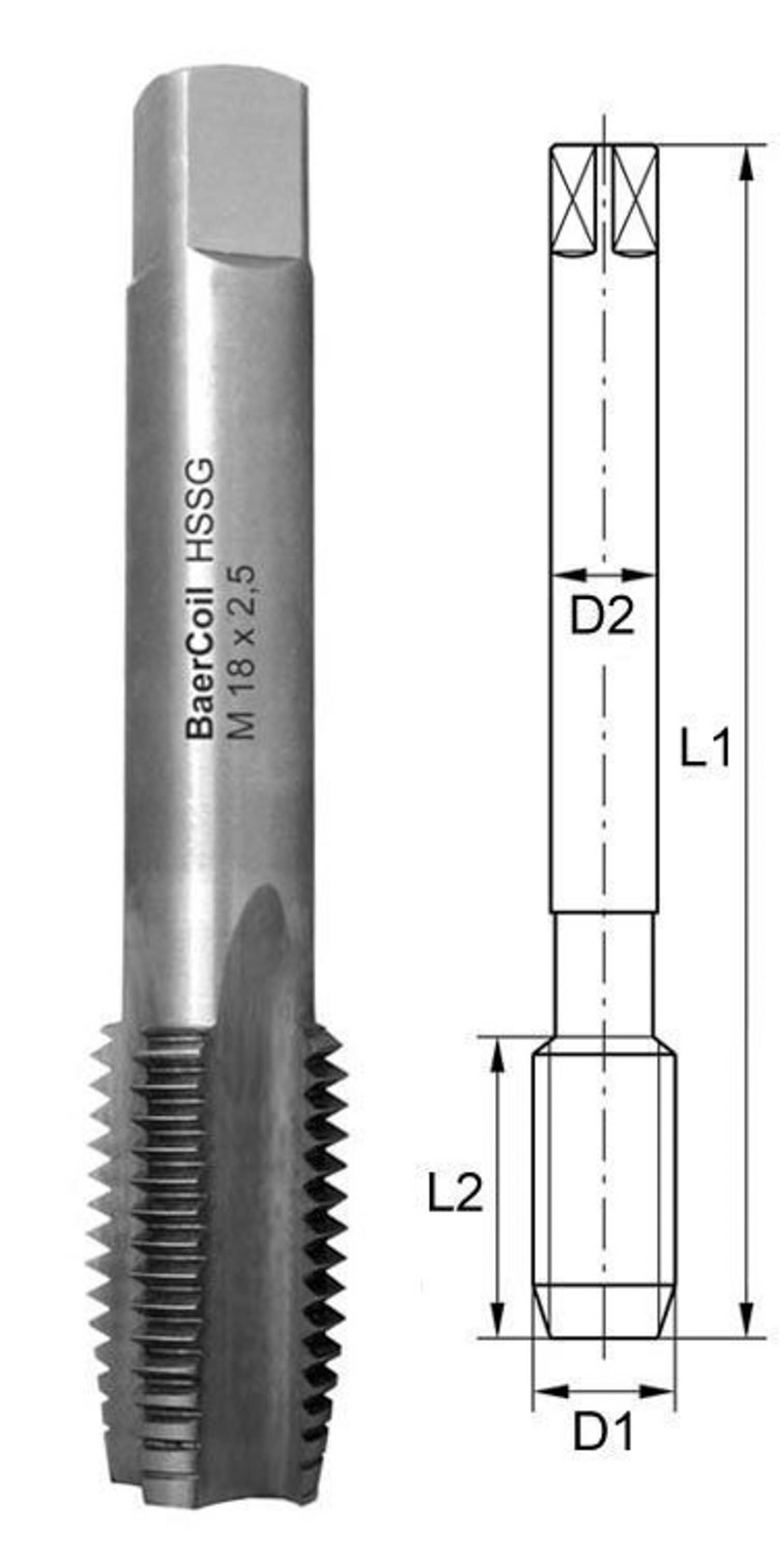

Technical drawing

| D1 |

13,2 mm |

|---|---|

| D2 |

10,8 mm |

| L1 |

91 mm |

| L2 |

42 mm |

| Diameter |

7/16 |

| Square |

8,2 mm |

Application – Sample materials for taps

| Unalloyed construction steels | |

|---|---|

| 1.0035 | S185 (St33) |

| 1.0036 | S235JRH |

| 1.0038 | RSt37-2 |

| 1.0039 | S235JRG1+CR |

| 1.0044 | St44-2 |

| 1.0060 | E335 (St60-2) |

| 1.0116 | St37-3 |

| 1.0570 | St 52-3 |

| Alloyed construction steels | |

|---|---|

| 1.5415 | 15Mo3 |

| 1.5423 | 16Mo5 |

| 1.5622 | 14Ni6 |

| 1.7335 | 13CrMo44 |

| 1.7337 | 16CrMo44 |

| 1.7715 | 14MoV63 |

| Free-cutting steels | |

|---|---|

| 1.0711 | 9S20 |

| 1.0715 | 9SMn28 |

| 1.0718 | 11SMnPb30 |

| 1.0721 | 10S20 |

| 1.0723 | 15S20 |

| 1.0726 | 35S20 |

| 1.0737 | 9SMnPb36 |

| 1.0758 | 60SPb20 |

| Case-hardening steels | |

|---|---|

| 1.0401 | (C15) |

| 1.7016 | 17CR3 |

| 1.7131 | 16MnCr5 |

| 1.5919 | 15CrNi6 |

| Quenched and tempered steels unalloyed | |

|---|---|

| 1.0402 | C 22 |

| 1.1151 | C22E (Ck22) |

| 1.0503 | C 45 |

| 1.1191 | C45E (Ck45) |

| Cast steel | |

|---|---|

| 1.0420 | GS-38 |

| 1.5419 | GS-22 Mo 4 |

| 1.6750 | GS-20 NiCrMo3 7 |

| 1.7357 | GS-17 CrMo 5 5 |

| Malleable cast iron | |

|---|---|

| 0.8145 | EN-GJMB 450-6 |

| 0.8170 | EN-GJMB 700-2 |

| 0.8045 | EN-GJMW-450-7 |

| 0.8055 | EN-GJMW-550-4 |

| Pure copper low-alloyed | |

|---|---|

| 2.0240 | CuZn15 |

| 2.0265 | CuZn30 |

| Brass short-chipping | |

|---|---|

| 2.0401 | CuZn39Pb3 |

| Brass long-chipping | |

|---|---|

| 2.0321 | CuZn37 |

| 2.0335 | CuZn36 |

| 2.0360 | CuZn40 |

| Aluminum cast Si > 5-12 % | |

|---|---|

| 3.2161 | G-AlSi8Cu3 |

| 3.2163 | G-AlSi9Cu3 |

| 3.2381 | G-AlSi10Mg |

| 3.2583 | G-AlSi12(Cu) |

| Lamellar graphite cast iron | |

|---|---|

| 0.6010 | EN-GJL 100 (GG-10) |

| 0.6020 | EN-GJL 200 (GG -20) |

| 0.6025 | EN-GJL 250 (GG-25) |

| 0.6030 | EN-GJL 300 (GG -30) |

| Copper-tin alloy (bronze) short-chipping | |

|---|---|

| 2.1090.01 | G-CuSn7ZnPb |

| 2.1086.01 | G-CuSn10Zn |

| 2.1097 | G-CuSn5ZnPb |

| Pure copper, low-alloyed copper | |

|---|---|

| 2.0240 | CuZn15 |

| 2.0265 | CuZn30 |