Cutting Threads in Wood – Is It Even Possible?

Wood is generally considered a flexible and easy-to-work material, making it especially popular among hobbyists and DIY enthusiasts. However, there is one area of craftsmanship where wood often presents challenges—when it comes to threading.

Threads provide a stable, practical, and visually appealing way to connect two components. They can be cut into many materials. You may have wondered if you can easily use your thread tap on wooden components. Unfortunately, it’s not that simple. In this blog post, we’ll explore why this is the case, what challenges arise, and whether there’s still hope for those who want to cut threads in wood.

The Material Wood – Its Unique Characteristics

Let’s take a closer look at the material we’re dealing with. Wood is a natural material and, as such, is not always perfectly predictable. While we can precisely determine the composition of metal, wood can sometimes surprise us. Even the same piece of wood often does not have consistent properties throughout. Engineered wood products, made by binding particles of different sizes with adhesives, offer a solution by providing more reliable and reproducible properties.

If we consider naturally grown wood, we must acknowledge that there is more than just one type of wood. Spruce, for example, has completely different properties from mahogany. Here, we primarily focus on the hardness of the respective wood type. However, other factors such as density and elasticity also play a role in selecting the right wood. Particularly in construction wood, tensile, compressive, and bending strength are critical factors.

Cutting Threads Directly in Wood

Cutting threads directly into wood can work under certain circumstances. However, the load-bearing capacity of the resulting screw connection can vary greatly. You should never use this method for heavy components or in safety-critical applications. For smaller craft projects and threads that do not need to bear significant loads, it is at least worth a try. Whether it succeeds depends on the wood type and the thread size.

Influence of the Wood Type

If you want to cut a thread into wood, you should definitely use a hardwood such as maple or beech. With softwood, you will typically either fail to create a clean thread from the start or notice during use that the screw spins freely and does not provide a secure hold.

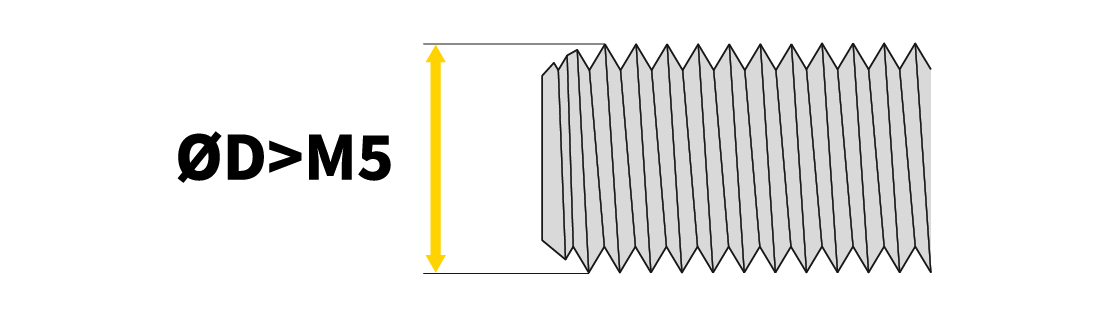

Influence of Thread Size

Thread size is also a factor in determining whether threading in wood will be successful. Small and fine threads cannot be created in wood. It’s worth experimenting with sizes starting from M5. The larger the thread, the better your chances of success!

Tips for Creating a Screw Connection in Wood

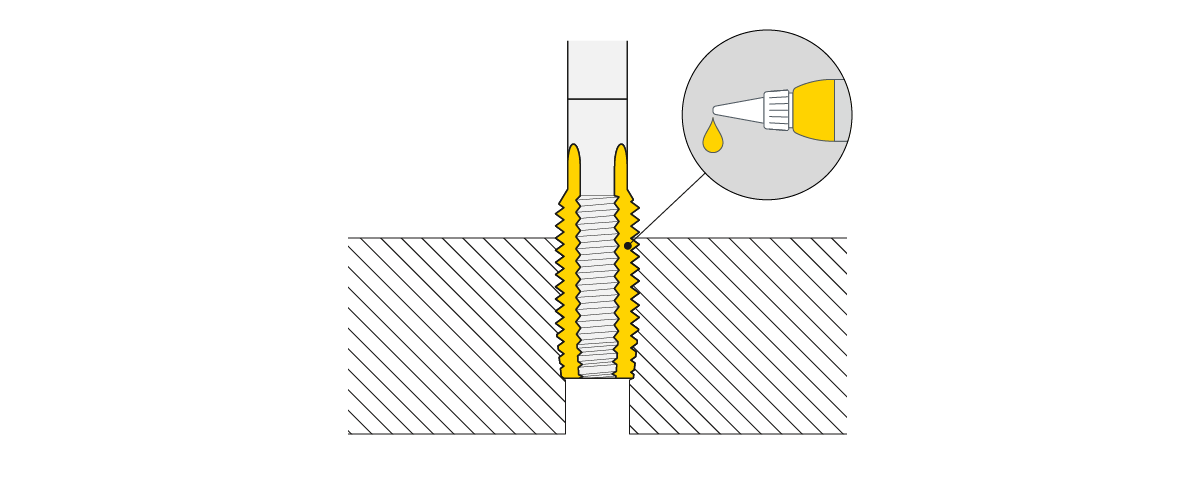

Although there is never a guarantee that threading in wood will succeed and the screw connection will hold, you can take several measures to improve your chances. Similar to threading in metal, the focus here is primarily on lubrication and chip removal.

You can use a suitable oil, such as linseed oil, as a lubricant for wood threads. Especially for longer threads, you should repeatedly pause and remove the wood chips from the borehole. You can secure screws in the wood thread with a bit of glue, but be cautious—whether you will be able to loosen the screw connection later is uncertain.

Tools for Threading in Wood Materials

In addition to the method of cutting threads directly into wood using a standard thread tap, there are several other options available.

Thread Inserts for Wood

You can use a thread insert such as a T-nut or screw-in insert. These are metal components with internal threads, enabling stable connections even in wood.

Thread Taps for Wood

There are also special thread taps designed specifically for use in wood. These can create both external and internal threads. While these tools make the threading process itself easier, they do not improve the load-bearing capacity of pure wood connections.

Conclusion: Cutting Threads in Wood – Is It Worth It?

It may feel promising when the thread tap glides through the wood like butter, but appearances can be deceiving. In most cases, cutting threads directly into wood is not a good method for creating a secure screw connection. For large threads in hardwood, you can test whether the resulting thread meets your requirements. For softwood, small threads, or fine pitches, this method is strongly discouraged.

Wood threads may be sufficient for creating decorative elements or as a design feature on a wooden rod. However, when a screw connection is under heavy load or when you need to screw in and out multiple times, the limitations of wood threads become evident. Always keep these limitations in mind when working with this natural material.

But why bother cutting threads in wood when there are so many better alternatives? Are you looking for threading tools for various materials and thread standards? Then don’t miss our extensive selection in the BAER online shop. There, you’ll find everything you need for threading. Our friendly customer service team is always available by phone or via our contact form to assist with your questions and inquiries.