Precision threading tools

Threading tools strong as a bear

for maximum precision

Threading tools strong as a bear for highest precision

For successful thread machining, you need high-quality and perfectly ground tools that you can always rely on. Whether taps or thread formers - with tapping tools from BAER, nothing can go wrong.

We accompany our taps all the way from raw material to delivery. At BAER, everything comes from a single source. This enables us to consistently deliver the high quality that our customers expect from us. See our wide range of products for yourself in the store.

BAER Toolfinder

The direct way to the tool from your screw tap manufacturer BAER

Toolfinder

Topseller

About us

Strong products from your screw tap manufacturer BAER

As a screw tap manufacturer, we know: To make threading a success, you need high-quality and perfectly ground threading tools. And we are proud to be able to offer you that as a screwe tap manufacturer. Highest precision is required in thread machining. Even small inaccuracies can result in threads that are not true to gauge, i.e. cut too large or too small. In the worst case, a component then becomes unusable.

At BAER, we accompany our screw taps all the way from raw material to delivery. Since we control several production sites and are a screw tap manufacturer, everything comes from a single source. This allows us to guarantee consistent quality that you can rely on. And you as a customer are part of it! In exchange with you, new ideas arise that we can incorporate into the manufacturing process. In this way, we work every day to continuously improve and to respond even more precisely to the needs of our customers.

Personal advice+49 6203 4048 79 0

Your advantages

Good reasons for BAER

BAER blog

This is how screw tap manufacturers like BAER produce tools for the thread machining

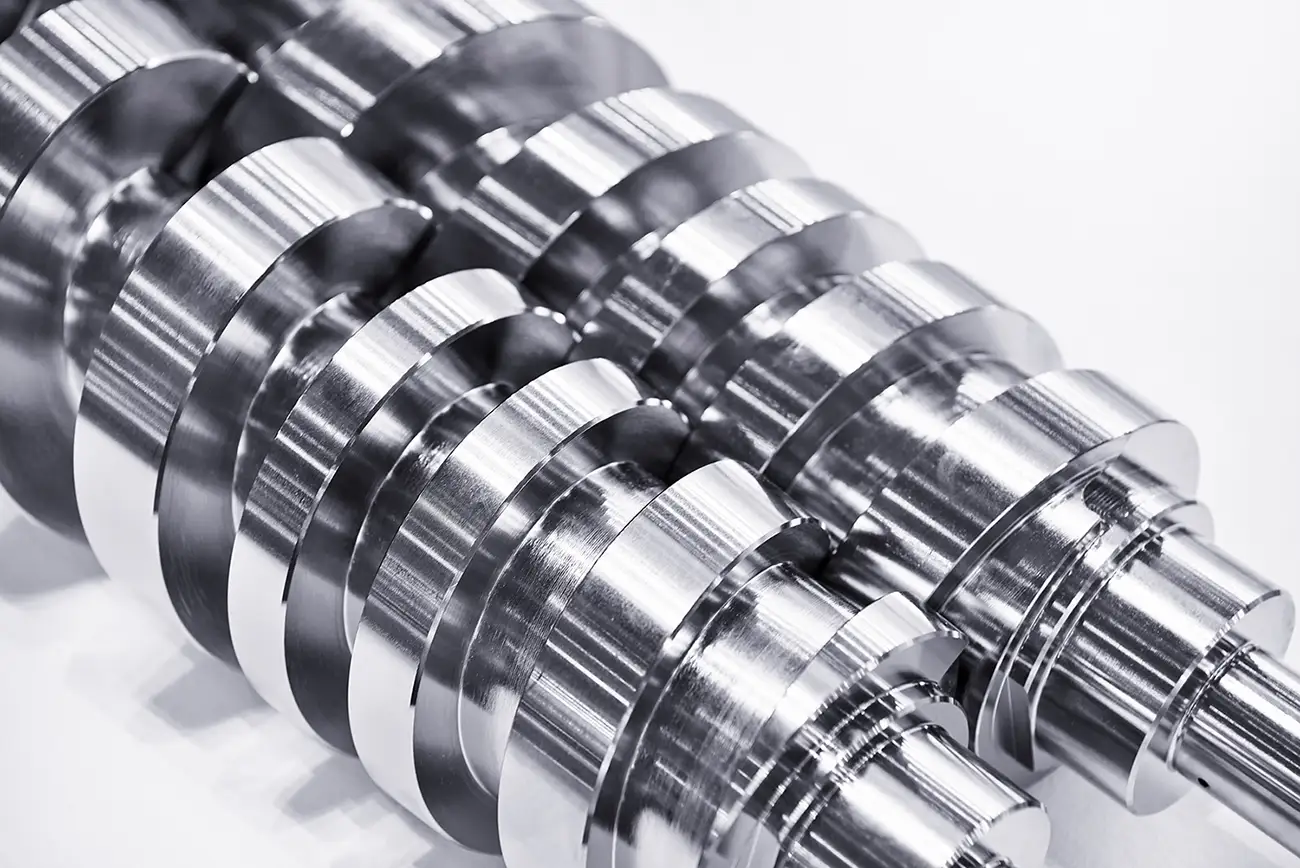

As screw tap manufacturers, we would like to familiarise you a little more closely with the manufacturing process of our tools. It all starts with the materials used. As a manufacturer of screw taps, we pay particular attention to quality here. If a screw tap manufacturer uses inferior steel, there is always a risk that both the thread and the tap will be damaged at thread machining and will not have the desired tool life time quality.

That is why we only use the best high-performance high-speed steels. In this material group, screw tap manufacturers find particularly hard steels that are heat-resistant and have outstanding cutting properties. These alloys provide the perfect basis for a long tool life time. After all, you should be able to rely on the quality of our products for thread machining for a long time.

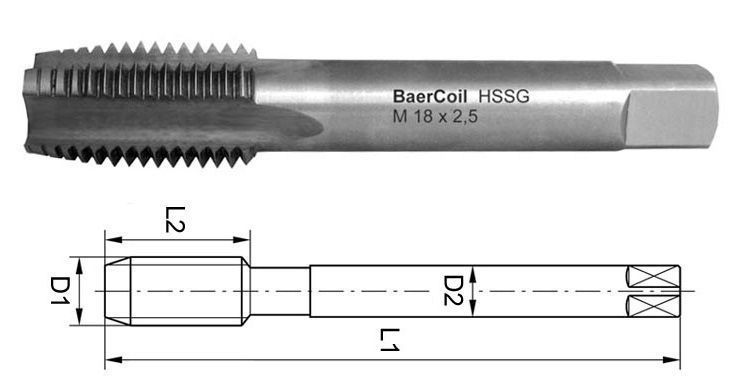

The screw tap manufacturer produces a blank from the steel, which is initially still soft. In a special hardening process, the blank is hardened and alternately heated and cooled. Tap manufacturers refer to this step as tempering. This ensures the special hardness of the later drill and makes the hardness structure homogeneous. Then screw tap manufacturers grind the form. The flutes, the chamfer and the thread itself are precisely worked with state-of-the-art machines. Great care is required here, because the work is literally in the micrometre range. The surface of the tap and the machining of the cutting edges are particularly important.

The finished screw tap then goes to our state-of-the-art warehouse. We have over 10,000 different tools and thread inserts ready for you here at any time. At BAER, you order directly from the screw tap manufacturer. This means you can always rely on our high stock availability and short delivery times. This means that you will always have the tool you need quickly at thread machining.

At screw tap manufacturer BAER we produce different types of taps

As a thread tap manufacturer, we have screw taps in a wide variety of designs in our online shop. But what are the actual differences between the tools for thread machining? We bring light into the darkness!

Basically, as a screw tap manufacturer, we distinguish between hand taps and machine taps. Although these two types are similar in design, they are used differently. Hand taps are suitable for manual use. They are usually offered by tap manufacturers in sets of three taps each, which are used in a specific sequence at thread machining.

Machine taps can only be used with a machine. These are often so-called single-cut taps. This means that with these taps the entire thread can be cut in one step. Machine taps enable many threads to be cut quickly in a short time, which is why they are mostly produced for the industrial sector by screw tap manufacturers.

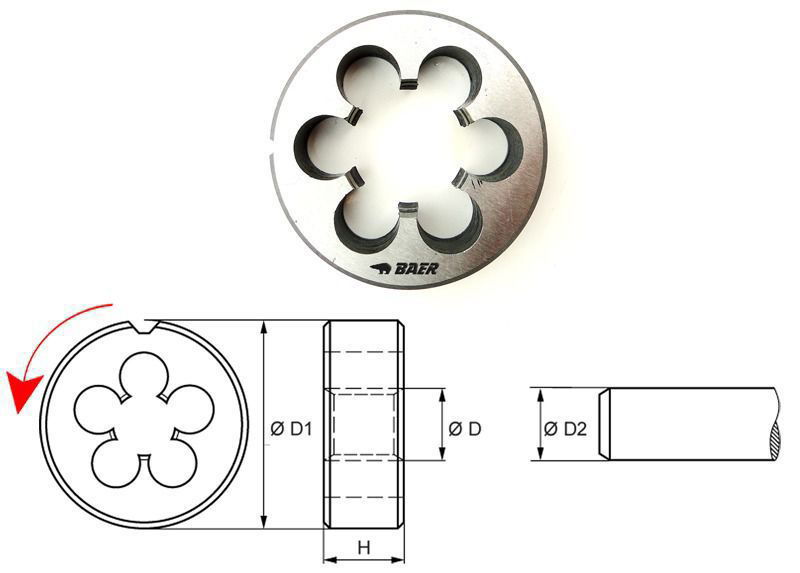

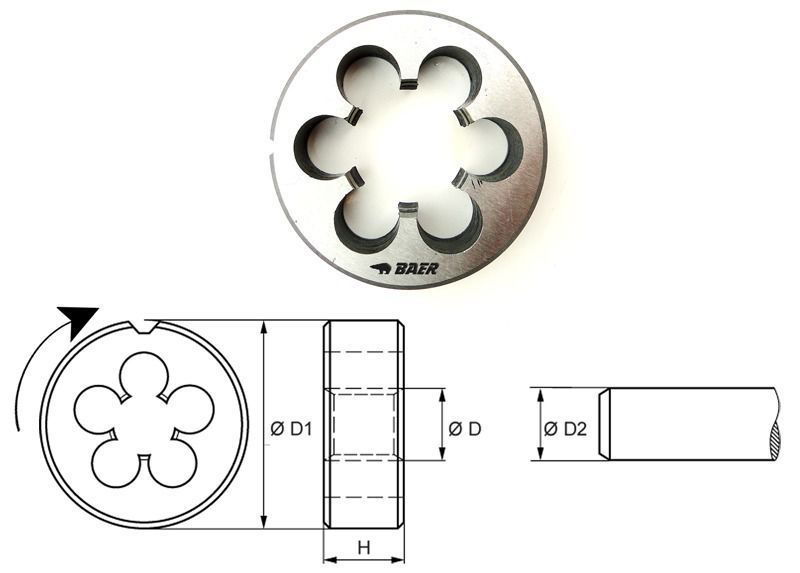

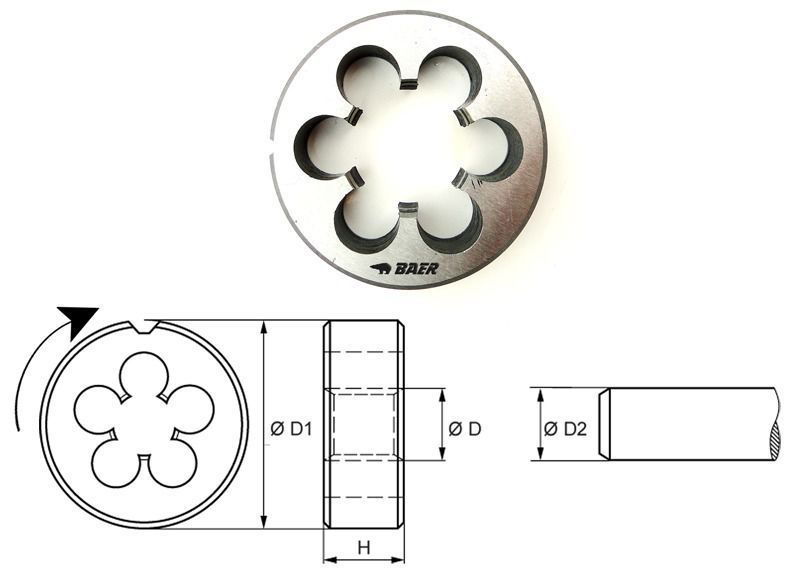

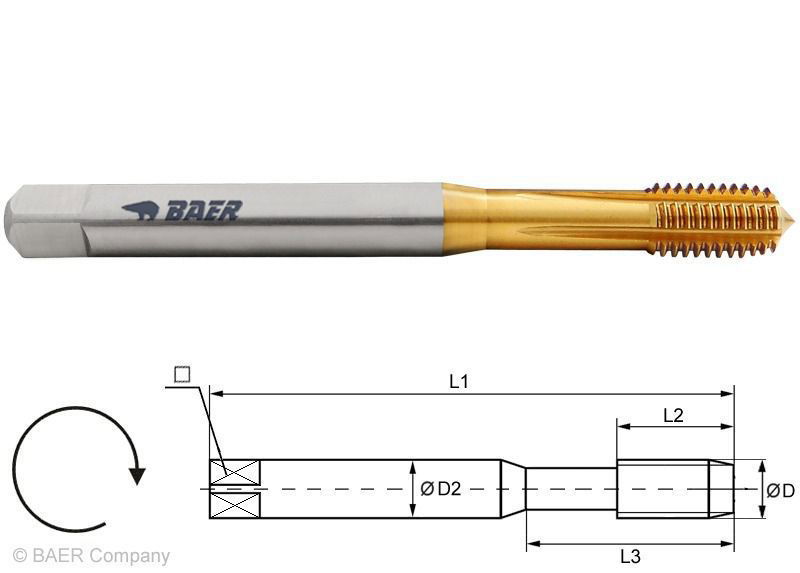

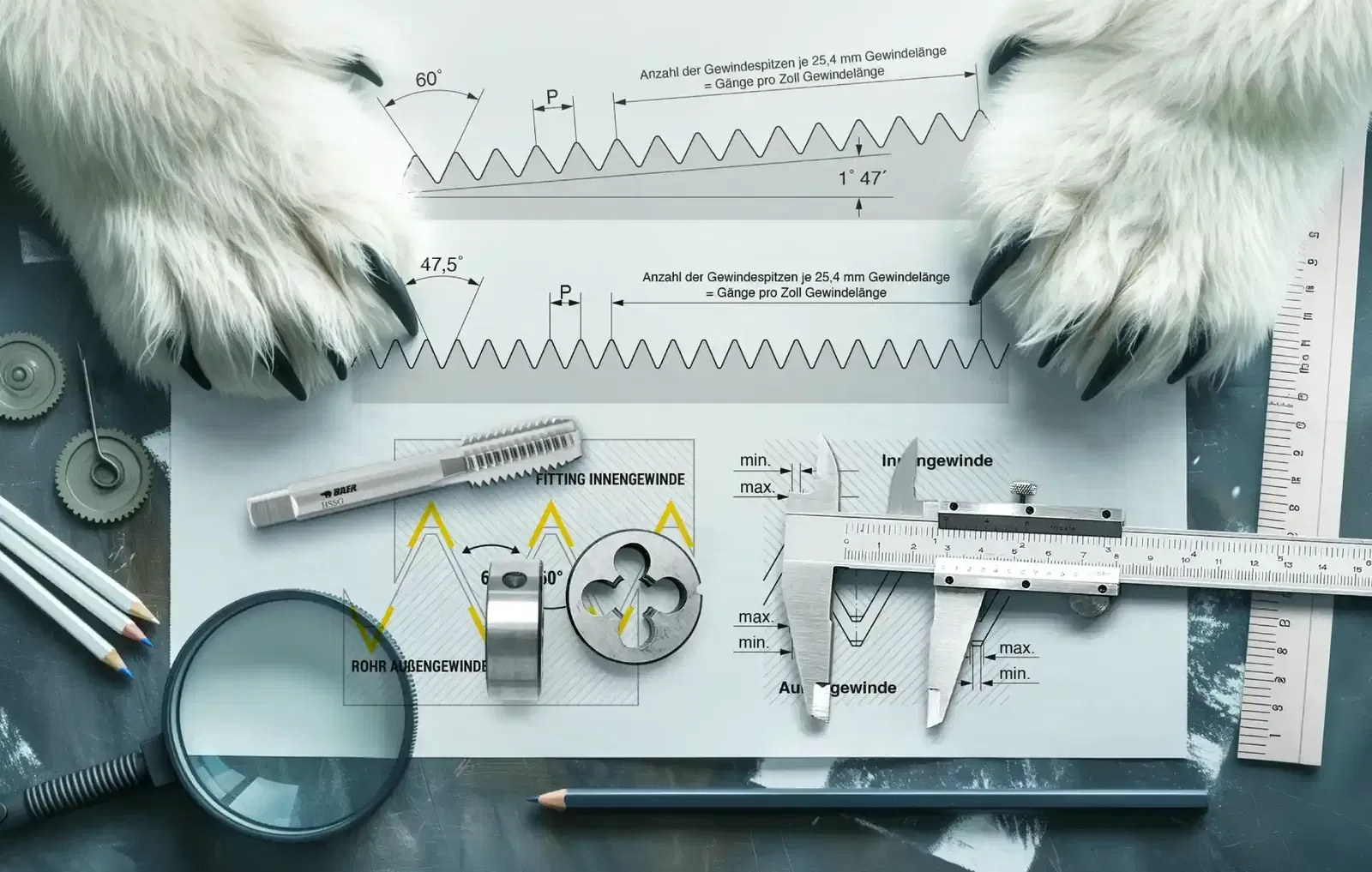

Whether made by the tap manufacturer for manual use or for the machine, all screw tap have a shank and a head. Further details can be seen on the head shape. For example, you can see here whether the screw tap is suitable for a blind hole or a through hole. However, the most important feature for screw tap manufacturers is the serrated profile, which is mainly responsible for the thread cutting process. Pitch is the term screw tap manufacturers use to describe the distance between the two tips of a tooth. The angle that results between the teeth is the thread angle. All these characteristics together define the thread type for tap manufacturers.

The characteristics of the thread type are specified for all tap manufacturers and are standardised according to international standards. This guarantees that tools of the same standard for thread dimensioning are used on all industrial applications, regardless of the place of use and screw tap manufacturer. As screw tap manufacturer, we take our task very seriously to follow the standards down to the smallest detail. In doing so, we see ourselves as an internationally operating tap manufacturer. In our range you will not only find the customary European standards, but also many other standards and special forms that are used worldwide.

At BAER you buy directly from the screw tap manufacturer

In our 40-year company history, we have gained quite a bit of experience as a tap manufacturer. Benefit from our extensive expertise by ordering your tools directly from the screw tap manufacturer. We are always there for you with advice and support, even after the purchase.

As we are screw tap manufacturers, we know our products inside out. We can answer your questions on the subject competently and well-founded down to the smallest detail. Whether you are looking for the right tool or need information on its use - our customer service is always available for you.

And if we don't have the special tool you need for your very special project? That's no problem at all for us as screw tap manufacturer. The satisfaction of our customers always comes first at BAER. That's why we do everything we can to contribute to the success of your building project. As a screw tap manufacturer, it is possible for us to respond flexibly to your special requests. We are happy to manufacture tools for you entirely according to your ideas. Of course, with the same care and precision that you are already used to from us as a tap manufacturer. And since sustainability is also close to our hearts, we also offer a regrinding service. This extends the tool life time of your customised products and, incidentally, does something good for the environment.

And there is another advantage for you as a customer if you order directly from the screw tap manufacturer. Since there are no middlemen when you order from the screw tap manufacturer, you benefit directly from our unbeatable factory outlet prices. You will only find so much quality for your money at BAER, the tap manufacturer you can rely on. If you have any questions, simply use the contact form!

How we manufacture our threading tools

Precision, care and a large experience are the ingredients that make BAER threading tools something very special. But how is a tap or thread former made from these ingredients? We take you on a journey through our production process. production process.

The materials are crucial

Everything starts with the materials used. Low-quality steel leads to an unclean thread and tool breakage. That is why That's why we choose high-quality high-speed steels (HSS) that are heat-resistant and have excellent cutting properties. have outstanding cutting properties.

From the blank to the tap

From the high-speed steel we produce a blank that is initially still soft and is alternately heated and cooled in the tempering process. is cooled. This ensures the special hardness hardness of the subsequent threading tools.

The grooves are then cut, cut and the thread itself are ground into shape. Great care is required here, as this involves work in the micrometer range. The surface of the tap and the machining of the cutting edges are particularly important. cutting edges.

From our warehouse to your home home

The finished threading tool is then sent to our state-of-the-art warehouse. We keep over 10,000 different tools and accessories in stock here ready for you at any time. BAER impresses with its high stock availability and short delivery times. Hardly in the shopping cart, already at your home!

At BAER you will find all types of threading tools

BAER is your strong partner for all questions relating to thread production. This is also reflected in our extensive range, in which you will find the right tool for you will find the tool you need for every thread.

Threading by hand or machine machine

Whether external thread or internal thread, you always have to choose between working by hand or with a machine. With us In addition to the right threading tools, you will also find holding tools, drill chucks, lubricants and other accessories.

Threading tools for all thread types thread types

Whether metric or imperial thread thread, fastening or movement thread - we cover all common and less common thread types. All our products naturally comply with current DIN requirements.

Other methods for thread production

When tapping and thread cutting tapping is by no means the end of the story. You will also find tools for thread forming in our range. You decide which process best suits your requirements!

At BAER, you buy directly from the manufacturer

Benefit from our extensive specialist knowledge and our experience from over 40 years of company history by ordering your tools directly from BAER. We are always on hand with help and advice, even after your purchase.

Custom-made products are also no problem for us. We are happy to respond flexibly to your wishes and manufacture tools for you according to your ideas. And because sustainability is also important to us, we also offer a regrinding service. This allows you to extend the service life of your threading tools and do something good for the environment at the same time.