The differential thread is a simple mechanism with a big impact

We have already looked at many different types of threads in this blog and have noticed time and again how versatile these structures actually are. They provide a firm hold, move loads, transmit movements, enable fine adjustments and can be delicate and sensitive as well as robust and indestructible, even under the most difficult conditions. The geometry of a thread's profile and its pitch are decisive in determining which category it falls into.

Today we want to take a look at the additional scope that arises when two threads are combined with each other. This type of design is known as a differential thread. The idea is an old one - the first drafts of the concept date back to the 17th century - but by no means outdated. Even today, differential threads are still used in many areas and have special tasks for which they are perfectly suited thanks to their special design. You can find out what these are and what makes a differential thread in this blog post.

What is a differential thread?

With a differential thread, there are two different threads on the same axle. If you are interested in railroads, you may now be thinking of a screw coupling with two opposing round threads, which is used to connect wagons together. Although the principle looks similar at first glance, the differential thread works quite differently.

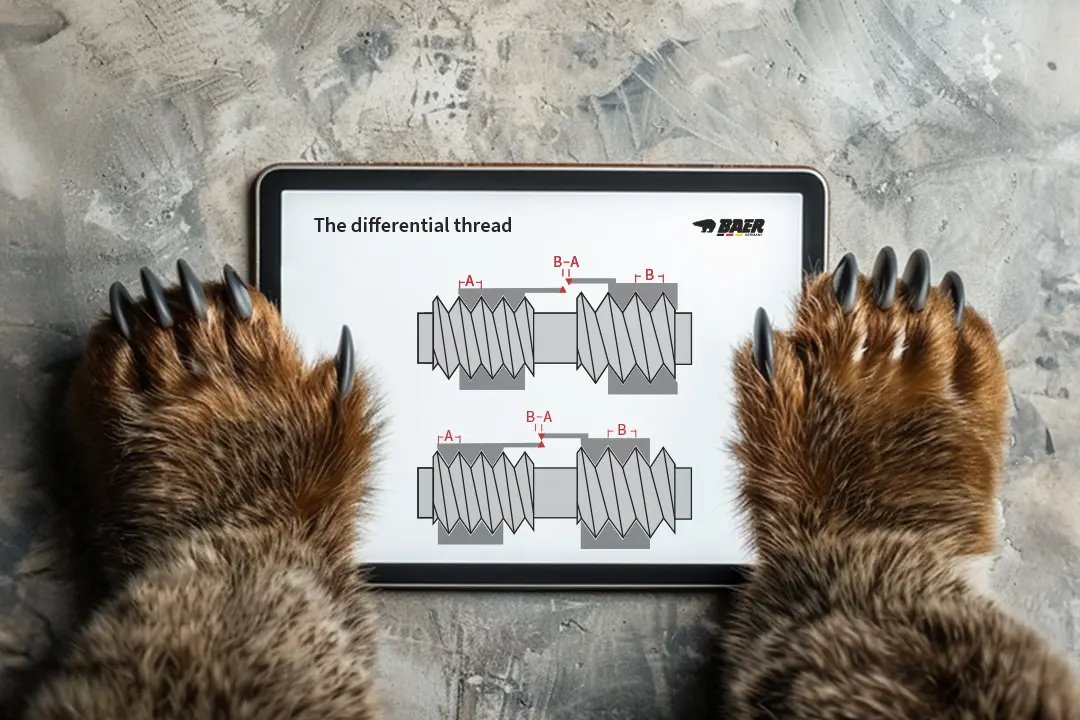

Firstly, in the vast majority of cases, the two threads of the differential thread are co-rotating threads and not a combination of left-hand and right-hand threads. Secondly, both threads have different pitches. This is the decisive criterion that defines a differential thread. Although various combinations are possible, there must always be a difference in the pitch. This is because it determines how the differential thread works.

How a differential thread works

So how does the differential thread work? As described, let's imagine a bolt on which a thread with a smaller pitch and then a thread with a larger pitch are attached one after the other. There is a matching nut on both threads of the differential thread. If we now turn the bolt, both nuts move in the same direction, as both threads have the same pitch. However, due to the different pitches of the differential thread, they do not move at the same speed. The distance between the nuts increases or decreases depending on the direction of movement.

The principle also works the other way round. A nut can also be equipped with a differential thread and fitted with the corresponding bolts.

A differential thread is used in a wide variety of areas

The functionality of a differential thread can be used for various and very different areas of application. The differential thread is suitable for changing the relationship between two components and making precise adjustments. The differential thread can therefore be used to move the lenses of a microscope in relation to each other and thus adjust the focus very precisely.

Another effect created by the different pitches of the differential thread is the possibility of firmly clamping two components. As the two components move at different speeds when rotating, the faster component will eventually reach the slower component. Both parts pull together and can be clamped together in this way.

Why the pitch difference is so important for differential threads

The pitch difference is not only the main feature of a differential thread. It is also the value that can be used to control the effect, as it determines how the distance between two nuts changes when they are turned in relation to each other. This value is referred to as the effective pitch of the differential thread. With metric threads, the effective pitch can be calculated by subtracting one pitch from the other. For example, if we work with a differential thread that combines an M 10 thread with a pitch of 1.5 mm with an M 12 thread with a pitch of 1.75 mm, the result is: 1.75 mm - 1.5 mm = 0.25 mm effective pitch. The distance between the two threads is therefore reduced by 0.25 mm per revolution. Very fine adjustments can therefore be made with the differential thread without having to resort to a fine thread and the associated complications. A small pitch difference also leads to higher clamping forces.

To perform the same calculation with the TPI values of inch threads, both pitches must first be converted into fractions according to the 1/TPI pattern, which means a little more calculation effort.

Can you produce a differential thread yourself?

You can also purchase bolts with a differential thread. However, due to the infinite number of possible combinations, it is quite possible that you will not find a product that combines the two desired threads on one axle. In such cases, you can simply cut these threads onto a bolt yourself.

As we have seen, the main thing you need to consider with differential threads is the choice of the two pitches and their relationship to each other. So think about what effective pitch you need for your project and then select two thread sizes that deliver the desired result. As the threads in the differential thread are completely separate from each other and each have their own component with a nut thread, there are hardly any limits. You can choose threads with significantly different diameters and even combine metric and imperial threads. This may even be necessary if you are aiming for a very specific effective pitch that cannot be achieved otherwise. You just need to be careful with the calculation and first convert the TPI value into a metric pitch in order to arrive at the correct values.

Do you already know which two threads you want to combine for your differential thread? Then head to the BAER online store to get the right threading tools! And if you get stuck, our customer service team will be happy to help and advise you.